Introduction

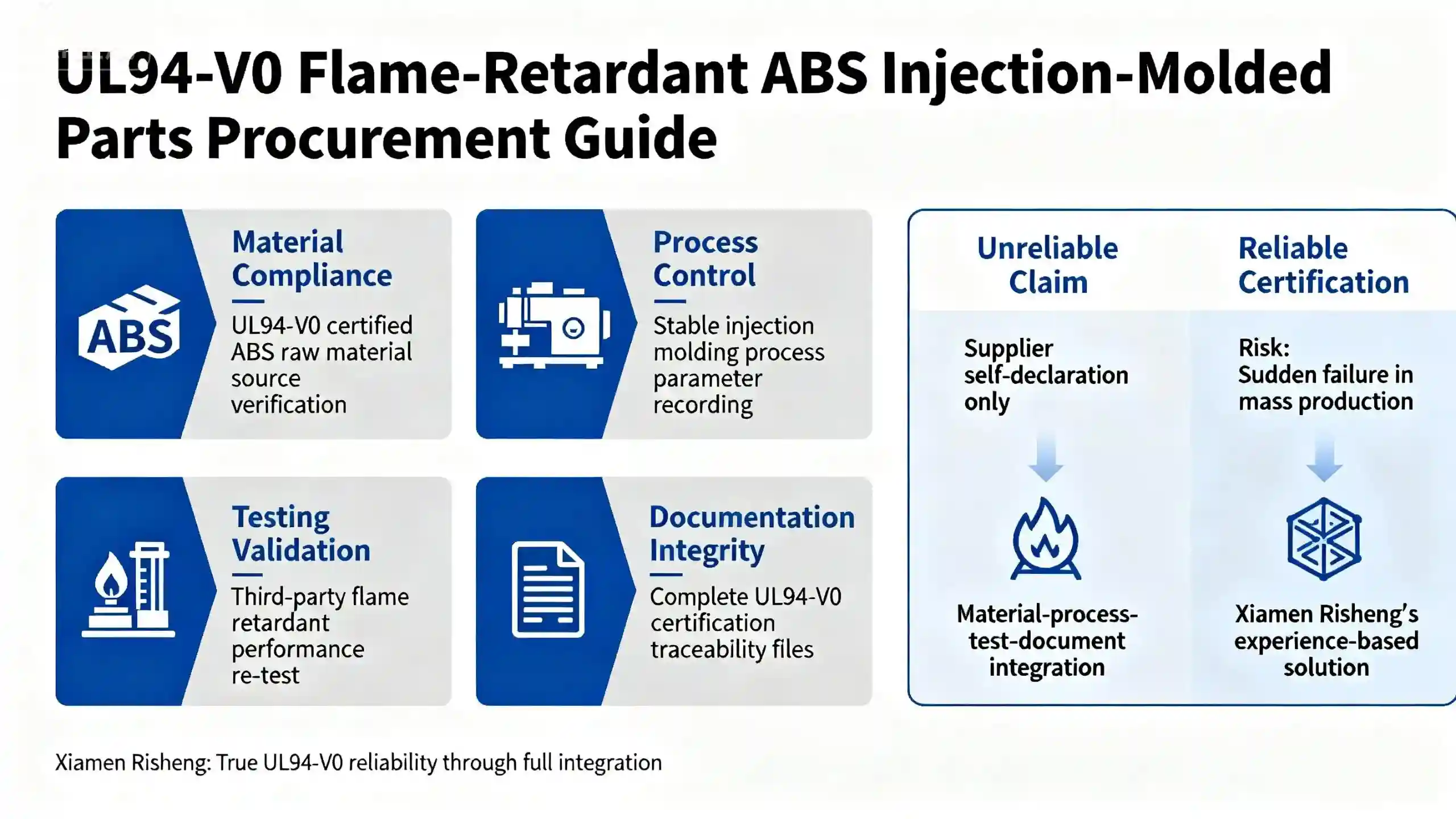

In the procurement of electrical equipment housings, ABS flame-retardant injection-molded parts are widely used in controllers, distribution units, and terminal enclosures, where flame performance directly affects safety compliance and market risk. Although many suppliers claim UL94-V0 ratings, the actual credibility behind these claims varies significantly, creating hidden uncertainty for buyers. Once flame-retardant ratings prove inaccurate, risks often emerge suddenly during mass production.

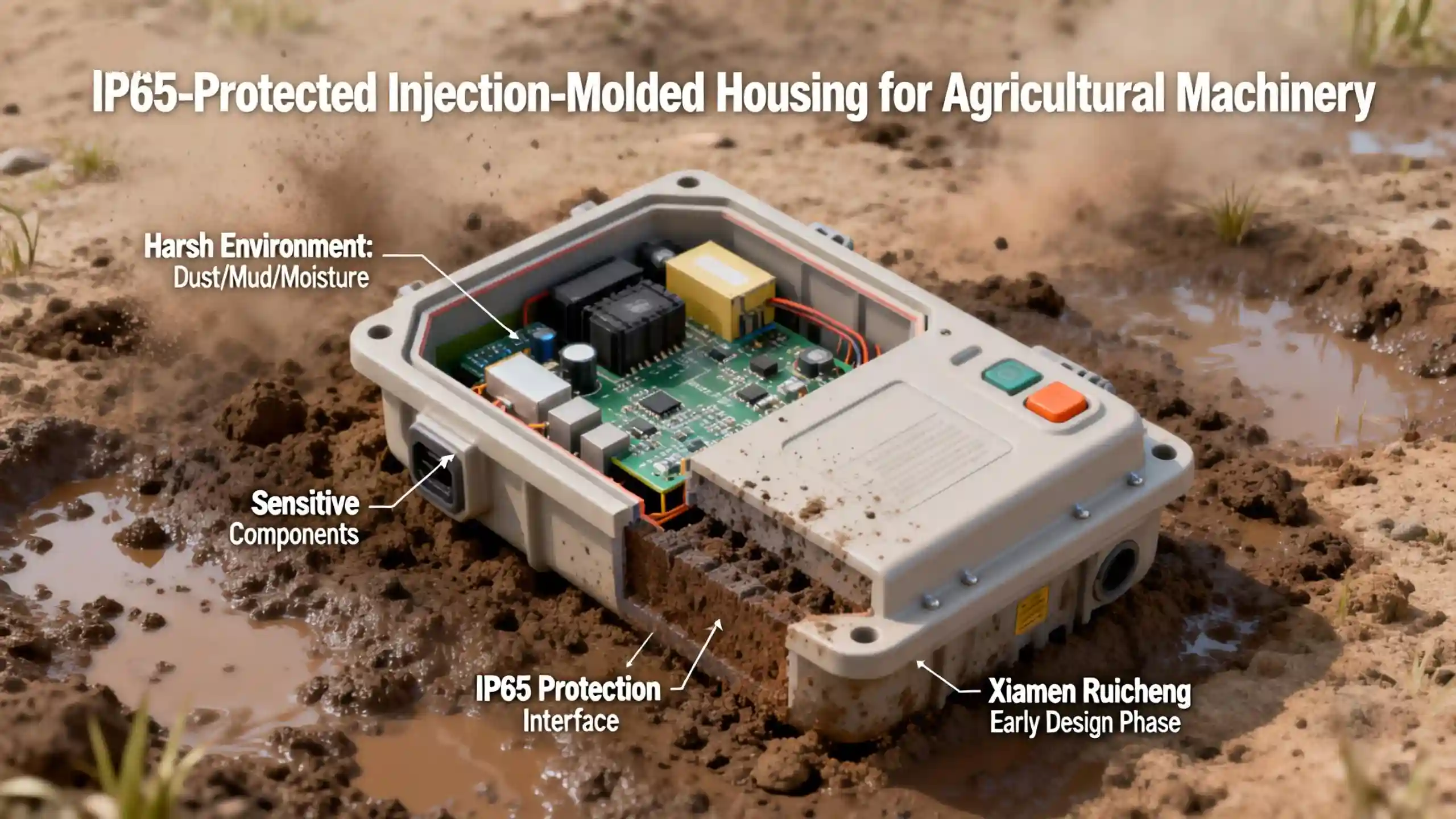

As procurement shifts from parameter comparison to risk control, decision-makers are paying less attention to labels and more attention to verification logic and supplier capability. Based on long-term experience in electrical housing injection molding, Xiamen Ruicheng has found that only when material, process, testing, and documentation are fully connected can UL94-V0 ratings remain truly reliable. The verification system itself has become a critical part of procurement safety.

Can the UL94-V0 Rating of Flame-Retardant ABS Be Independently Verified?

In real sourcing scenarios, UL94-V0 is not merely a material property but a combined result of resin formulation, flame-retardant dispersion, and injection molding conditions. Some suppliers provide only raw material declarations while ignoring the influence of molded structure on flame performance, leading to inconsistencies between certification and finished parts. A credible UL94-V0 verification must align records from the UL official database with the actual molded condition and recognized UL94 test methods.

Material traceability: Confirm resin grade and flame-retardant system via UL Yellow Card records.

Molding influence: Injection temperature and shear rate directly affect flame-retardant distribution.

Structural equivalence: Wall thickness and rib design must be equivalent to UL94 test specimens.

Documentation loop: Test reports, batch records, and production parts must be fully traceable.

🔥 Only a complete verification chain ensures UL94-V0 performance remains valid in production.

Does the Injection Molding Process Weaken ABS Flame Retardancy?

During injection molding, flame-retardant ABS undergoes high thermal and shear stress, which may cause additive migration or degradation if not properly controlled. Many buyers focus solely on material ratings while overlooking process windows, resulting in unexpected failures during audits or inspections. Only by integrating injection molding process control with a clear understanding of flame-retardant mechanisms can UL94-V0 performance be preserved in finished housings.

Temperature management: Excessive melt temperature may degrade halogenated or halogen-free additives.

Shear control: Screw speed and back pressure affect dispersion uniformity.

Mold design: Runner layout and gate position alter local burning behavior.

Process validation: Verification must be conducted on molded parts, not raw material samples.

⚙️ Flame retardancy is not inherent—it must be preserved throughout molding.

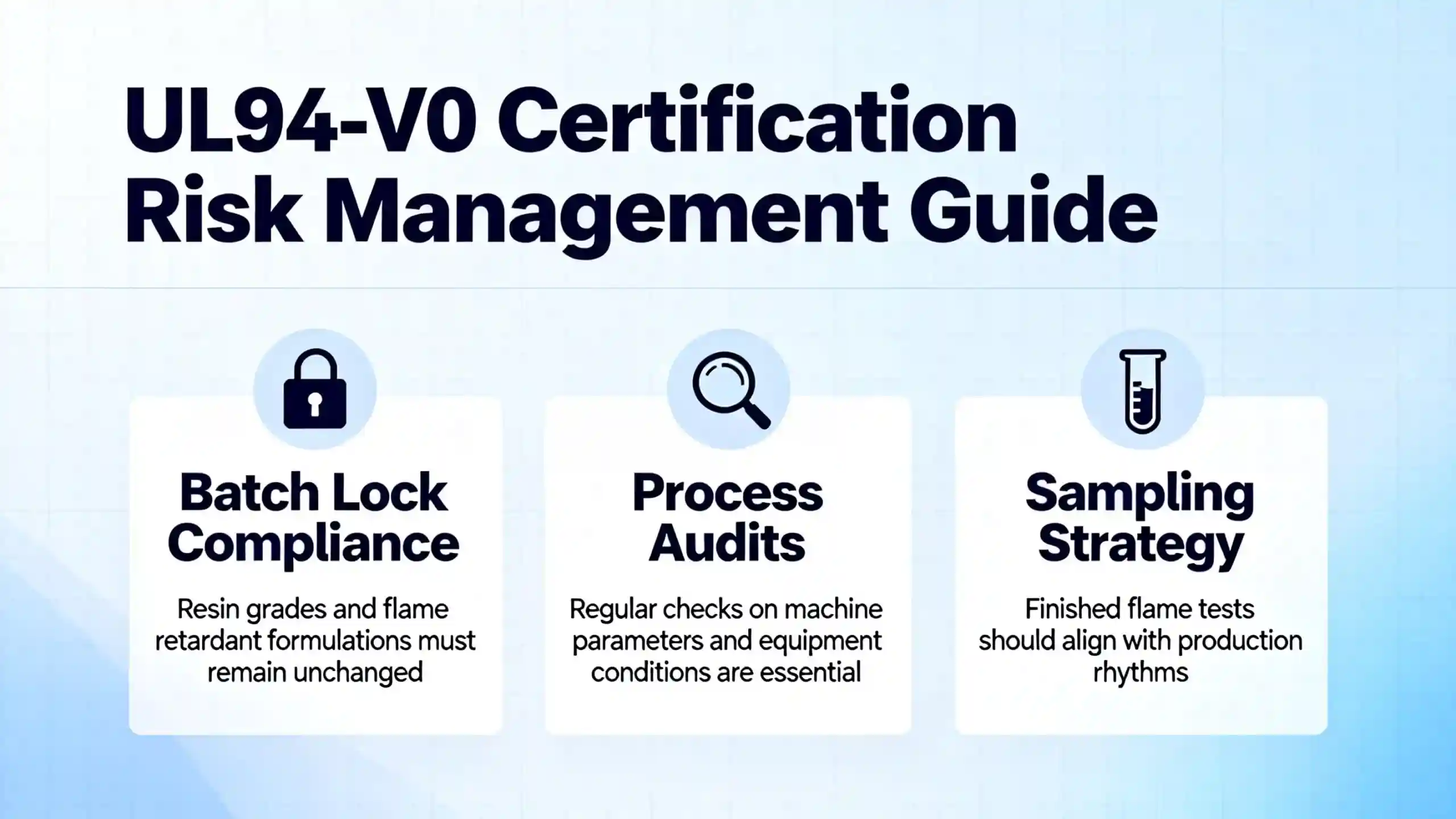

How Can UL94-V0 Certification Fail During Mass Production?

UL94-V0 failures typically occur when transitioning from prototype validation to full-scale production, often due to insufficient system-level control rather than isolated mistakes. If certification is confirmed only at the sample stage without continuous verification, risks multiply as volume increases. Embedding quality consistency control and structured batch testing management into supplier agreements is the key to preventing certification loss.

Batch locking: Resin grades and flame-retardant formulations must remain unchanged.

Process audits: Regular checks of machine parameters and equipment condition are essential.

Sampling strategy: Finished-part flame tests should follow production rhythm.

Responsibility definition: Contracts must define accountability and corrective actions.

🛡️ UL94-V0 is not a one-time result, but a continuously validated condition.

Key Checkpoints for UL94-V0 Flame Verification

| Verification Aspect | Common Practice | Risk Point | Xiamen Ruicheng Approach |

|---|---|---|---|

| Material source | Datasheet only | Grade mismatch | Full UL card traceability |

| Test sample | Raw resin bars | Not representative | Molded part testing |

| Process control | Experience-based | Batch fluctuation | Standardized parameters |

| Documentation | Single report | No traceability | Closed-loop batch records |

If you aim to lock in flame-retardant risk at the sourcing stage rather than react after mass production, we invite you to explore our verification system and contact us.

From Certification Documents to Production-Safe Decisions

In sourcing ABS flame-retardant electrical housings, real decisions extend beyond certificates into long-term production reliability. Through early technical involvement, mid-stage process locking, and ongoing consistency audits, Xiamen Ruicheng helps buyers transform UL94-V0 from paper compliance into production-level safety. This decision-companion approach significantly reduces compliance and recall risks.

1.Early evaluation: Align structure and flame-retardant systems at the design stage.

2.Process alignment: Complete dual validation of process and flame performance before mass production.

3.Ongoing monitoring: Maintain long-term tracking of batches and test results.

4.Risk mitigation: Define backup plans and responsibilities for unexpected changes.

FAQ – Common Procurement Questions

Question: What ensures the reliability of your UL94-V0 ABS electrical housings?

Answer: We use UL-certified material systems combined with molded-part testing and batch locking, ensuring flame performance remains consistent with mass-production conditions and fully traceable.

Question: What information is required for quick quotation and evaluation?

Answer: Please provide drawings, target flame rating, annual volume, and application environment, enabling us to deliver a quotation with process and verification recommendations.

Question: What are the MOQ and lead time for different order volumes?

Answer: Small-batch trial orders are supported, with optimized pricing and delivery schedules aligned to annual volume planning.

Question: How are flame-retardant inconsistencies handled in production?

Answer: Our batch traceability and re-testing mechanism allows rapid root-cause identification and corrective action, including rework or alternative solutions.

Question: Do you support customized flame-retardant or structural optimization?

Answer: Yes, we provide joint optimization of material systems and structures based on real application conditions, with clear timelines and cost evaluation.

Conclusion

The authenticity of UL94-V0 ratings in ABS flame-retardant electrical housings depends not on a single certificate but on a sustainable verification system. By integrating material selection, process control, and production management, buyers can truly control flame-retardant risk. Xiamen Ruicheng supports procurement decisions through long-term verification and production assurance. This is not just a compliance choice, but a responsible sourcing strategy for brand and market safety.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!