Introduction

In modern high-precision electronic devices and electrical systems, Electromagnetic Interference (EMI) is a universal and critical issue that must be addressed. If EMI is not effectively controlled, it can lead to degraded system performance, data errors, or even equipment failure. Therefore, seeking highly efficient and reliable EMI shielding solutions has become an industry consensus. Traditional metal shields are effective, but they have limitations in terms of cost, weight, and design flexibility.

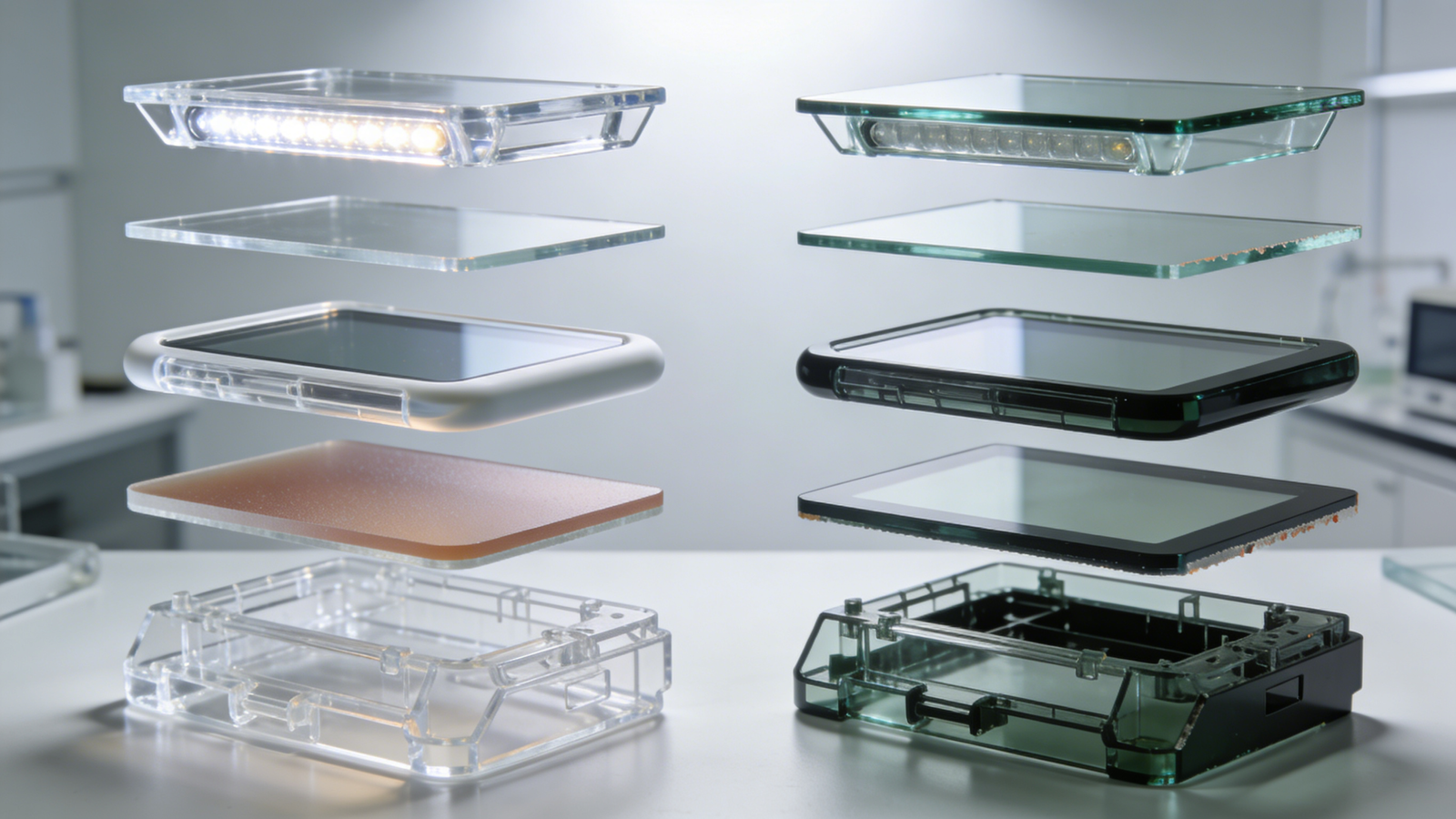

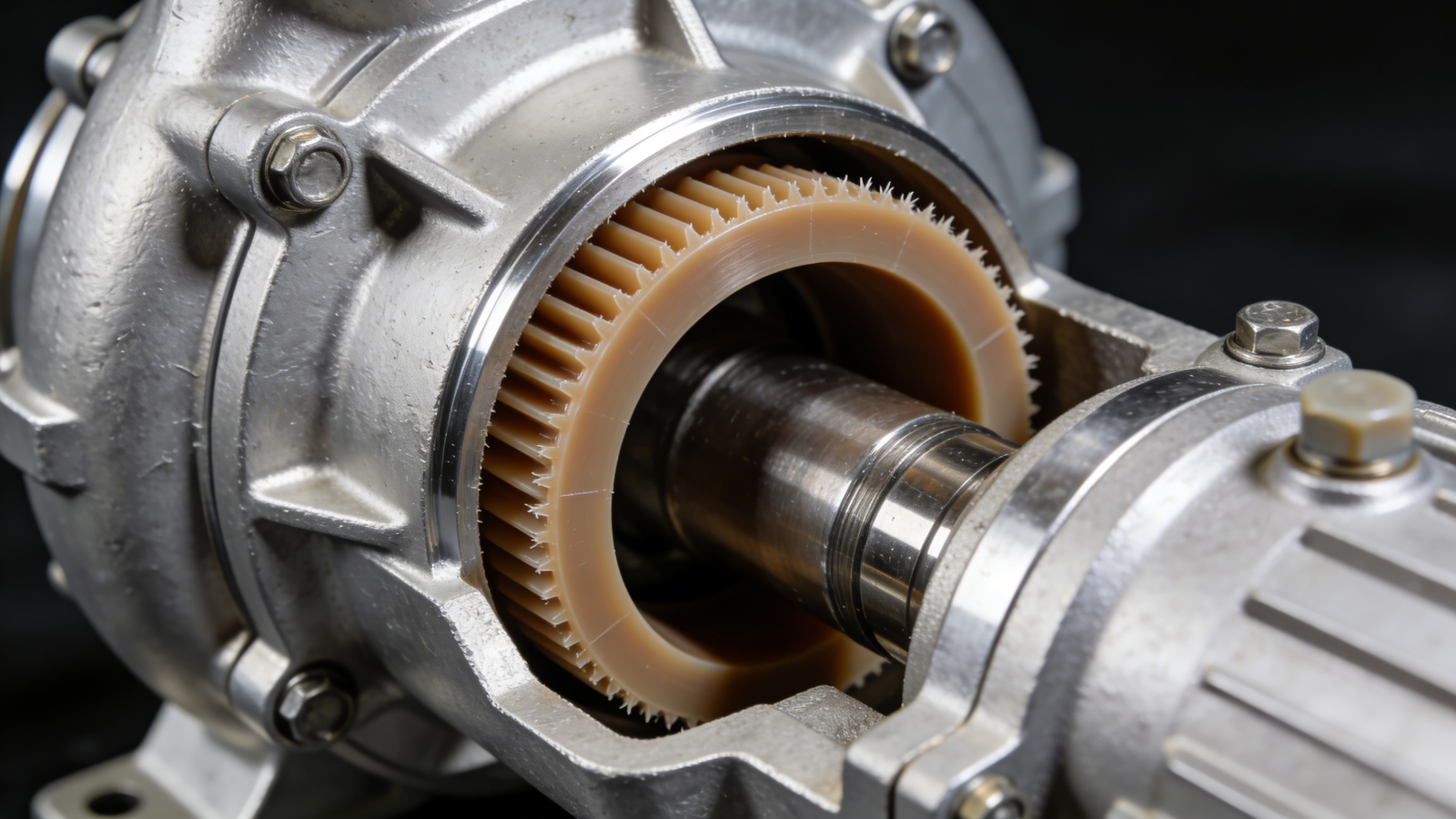

Injection molded Nylon (Polyamide) washers are emerging as a new choice for EMI protection, leveraging their excellent mechanical properties, chemical resistance, and lightweight nature. By adding specialized conductive or absorbing fillers to the nylon matrix, injection molded nylon washers provide structural support while simultaneously offering superior electromagnetic shielding functionality. This presents an innovative and economical path toward miniaturization and high performance in electronic products.

How Do Injection Molded Nylon Washers Eliminate EMI?

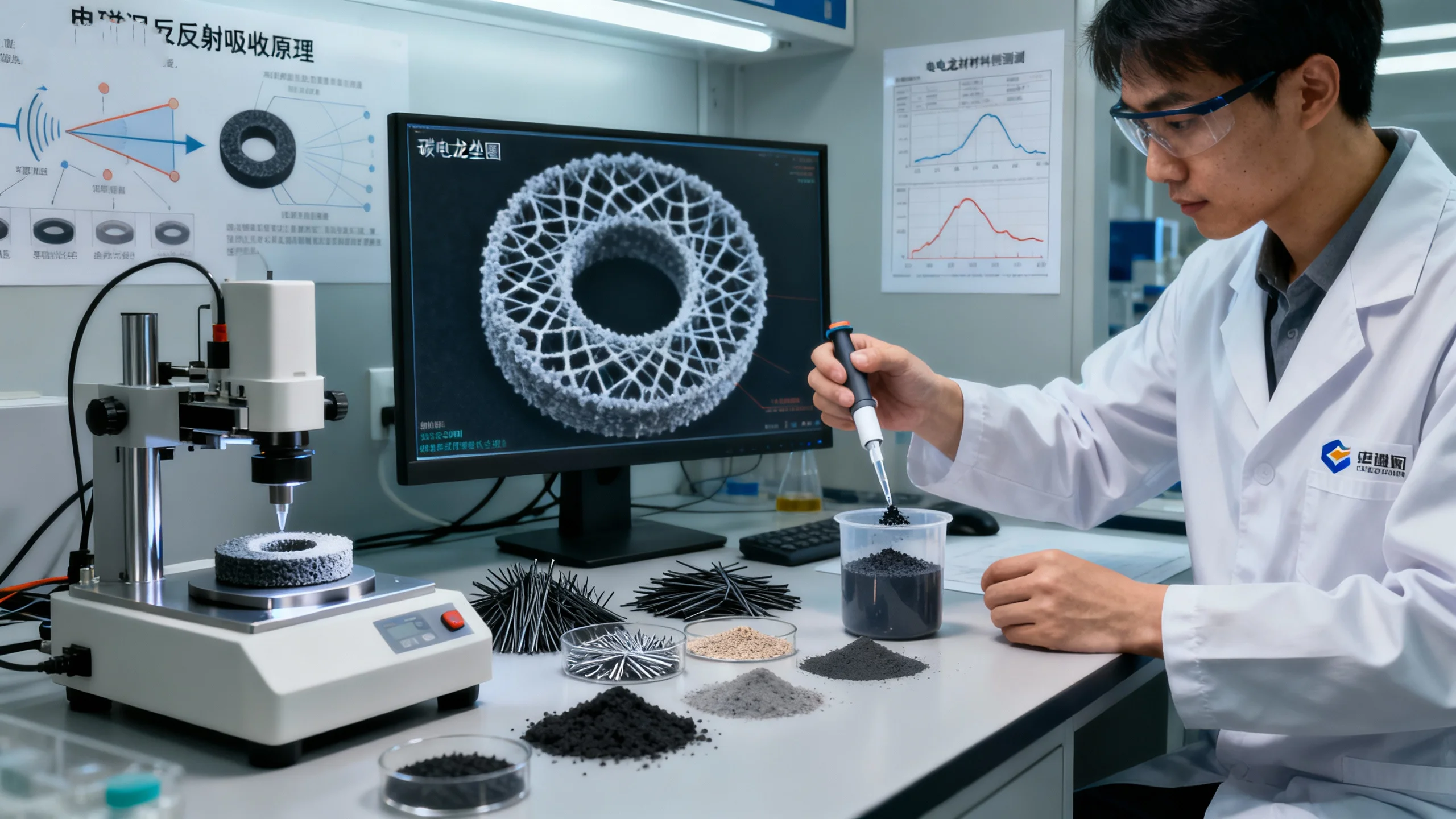

Injection molded nylon washers are not inherently conductive; the core of their EMI shielding capability lies in composite material modification technology. By precisely adding fillers such as conductive carbon materials (e.g., carbon fiber, carbon nanotubes), metal-coated fibers, or conductive powders into the nylon resin, a continuous conductive network is formed. This conductive network uses the principles of electromagnetic wave reflection and absorption to effectively block or attenuate the propagation of electromagnetic waves. The precision injection molding process ensures that these conductive fillers are uniformly distributed within the washer, thereby guaranteeing stable and consistent shielding effectiveness.

- Reflection Mechanism: The conductive fillers in the nylon washer form a low-impedance surface, where electromagnetic waves are reflected at the interface with the shielding body.

- Absorption Mechanism: Electromagnetic waves that are not reflected enter the washer interior, where they are attenuated by converting electromagnetic energy into heat through interaction with the conductive materials.

- Grounding Path: Conductive Filler Selection: The composite material provides a low-resistance connection point, facilitating the discharge of static charges and interference currents, acting as a grounding path.

- Injection Process Optimization: Precise control of the molding process ensures the continuity of the conductive network, maximizing the shielding potential.**

😁 Modified injection nylon achieves EMI shielding by using an internal conductive network for the reflection and absorption of electromagnetic waves.

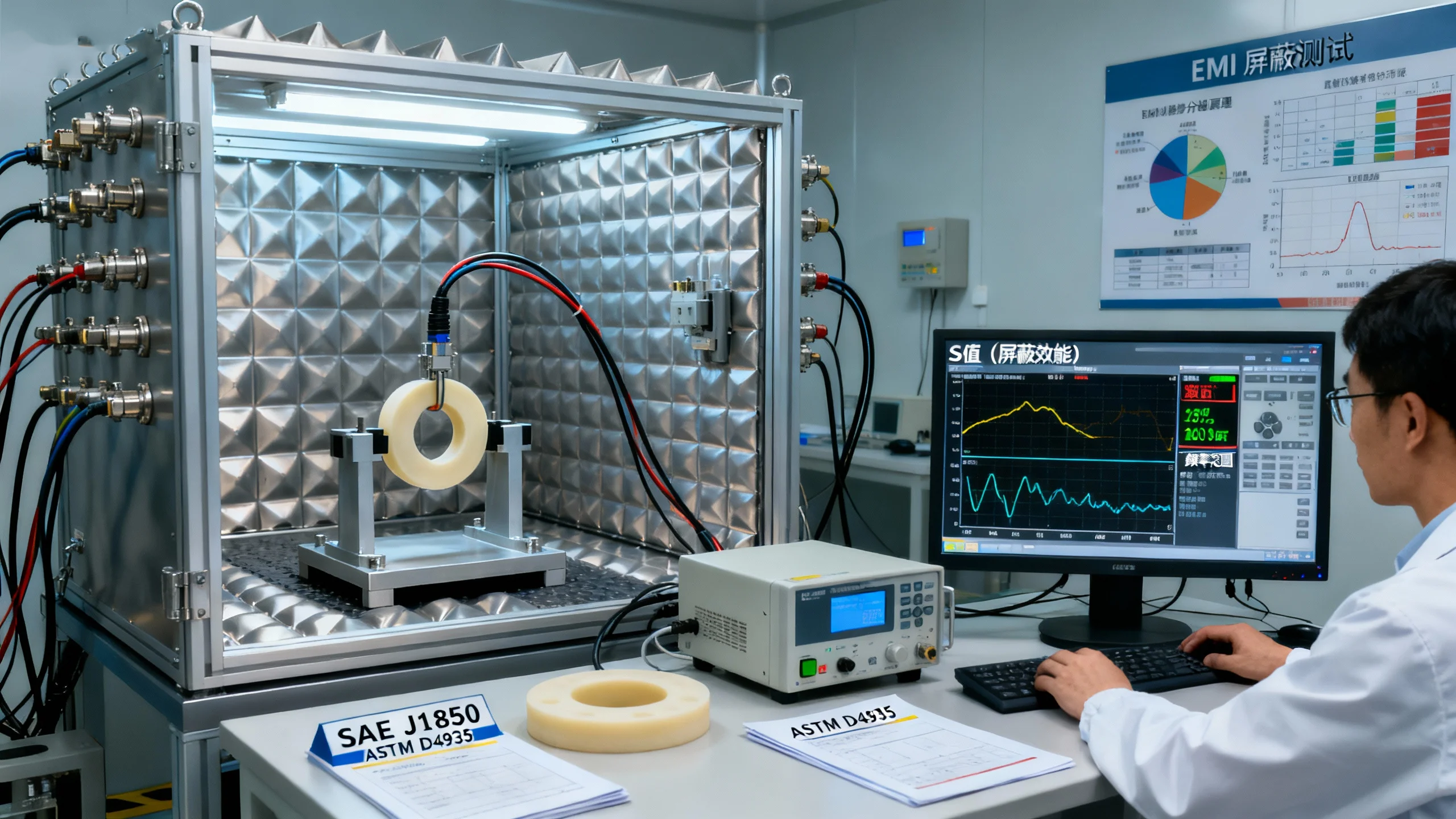

How to Evaluate the EMI Shielding Effectiveness of Custom Nylon Washers?

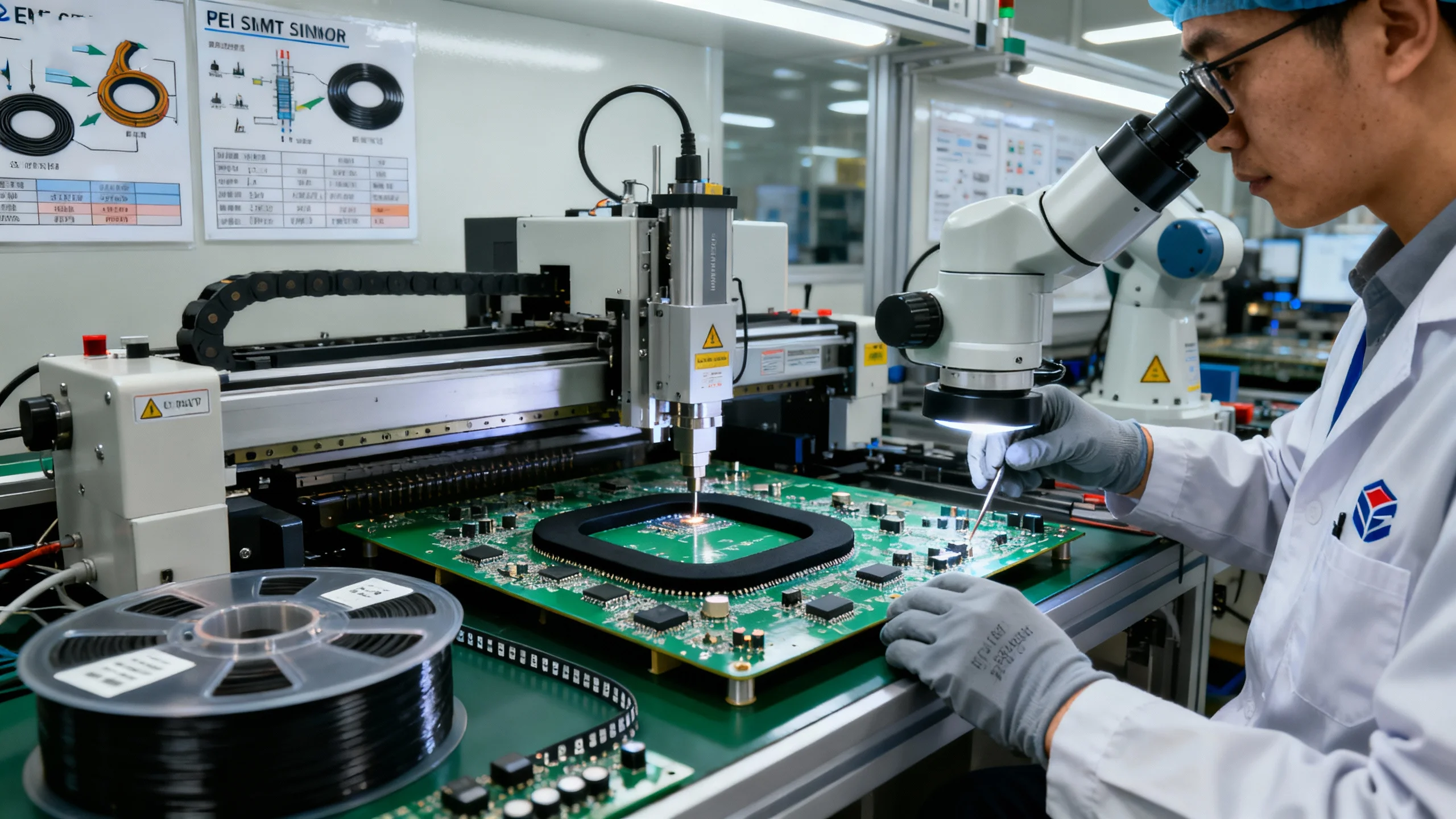

Evaluating the EMI shielding effectiveness (SE) of custom injection molded nylon washers is a critical step to ensure they meet the requirements of specific applications. Shielding Effectiveness (SE) is typically measured in decibels (dB), representing the degree of attenuation of electromagnetic wave energy penetrating the shielding material. Professional evaluation relies on standardized testing methods and precise instrumentation to ensure the accuracy and reliability of the data. Engineers select the most suitable composite material formulation and molding parameters based on the product's operating frequency range and the required level of interference suppression.

- Testing Standards: Industry standards such as SAE J1850 or ASTM D4935 are often employed to ensure the comparability of test results.

- SE Value Definition: Measures the ability of the shielding body to attenuate electromagnetic wave signals; a higher SE value indicates better shielding performance.

- Frequency Range: Shielding Effectiveness Testing: Must be tested specifically for the washer's actual application frequency range to ensure effectiveness within the target frequency band.

- Material Formulation: The type, proportion, and dispersion uniformity of the conductive fillers are adjusted according to the required SE value and mechanical strength.

🧐 EMI shielding effectiveness is assessed through standardized testing, where a high SE value signifies stronger electromagnetic interference suppression capability.

What are the advantages of choosing injection-molded nylon washers?

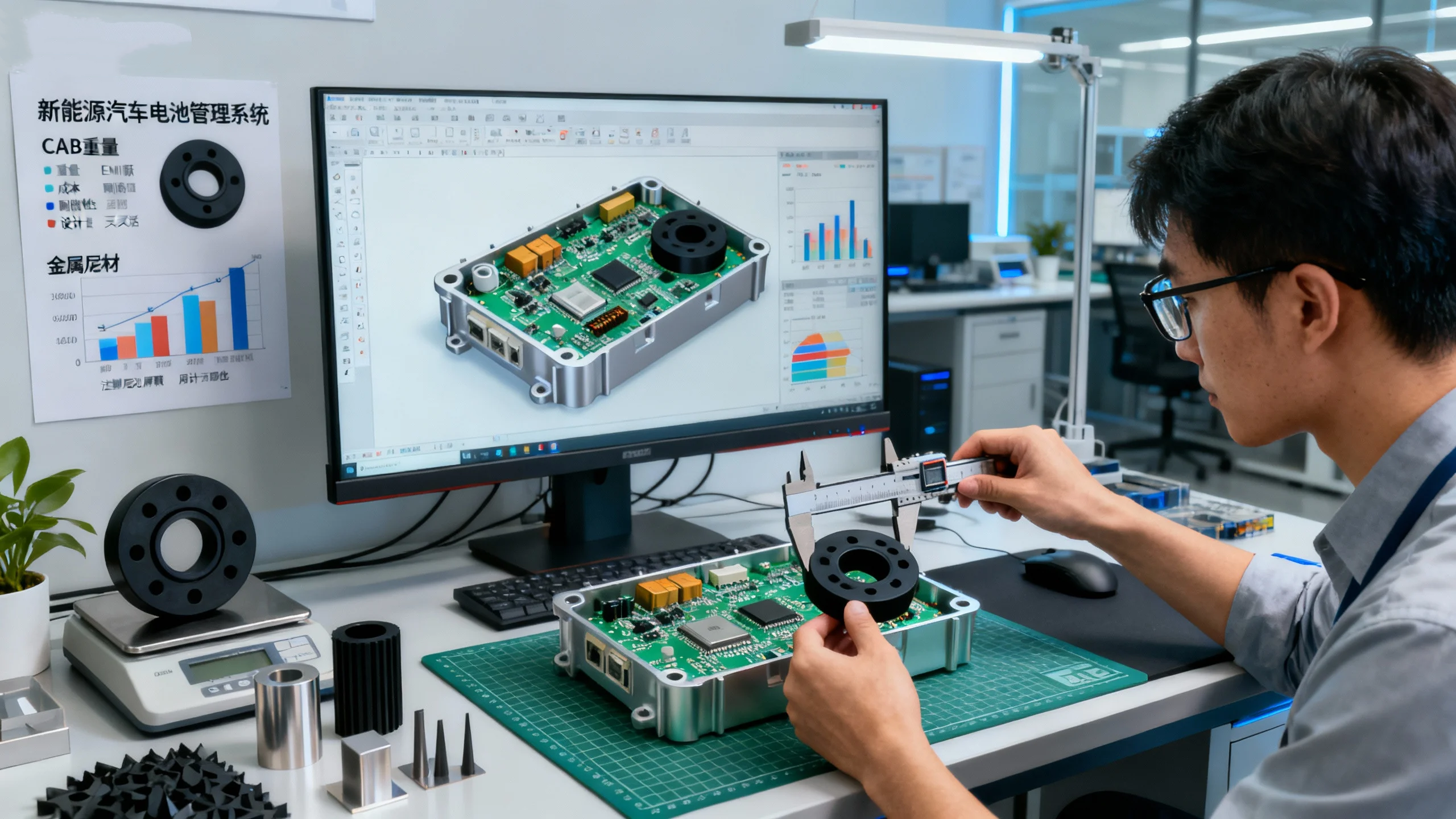

Choosing injection molded nylon washers for EMI shielding components offers advantages over traditional metal shielding in several aspects. The most significant are lightweight and design flexibility; nylon's density is much lower than metal, helping electronic devices meet weight reduction goals, while the injection molding process can easily achieve complex three-dimensional geometries, meeting the design requirements of confined spaces. This is particularly important for weight and space-sensitive sectors such as new energy vehicles, aerospace, and portable electronic products.

- Weight Advantage: The density of injection molded nylon composites is significantly lower than metal, contributing to the lightweight design of end products.

- Cost Efficiency: In mass production, the injection molding process has short cycles and high automation, often making it more cost-effective than machined metal parts.

- Corrosion Resistance: Nylon material offers excellent resistance to various chemicals and environmental factors, making it more durable than many metals.

- Design Integration: Injection molding allows for the integration of shielding functions with other structural functions into a single component, reducing the number of parts and assembly steps.

👍 Injection molded nylon washers offer commercial advantages over traditional metal shielding, including lightweight, lower cost, corrosion resistance, and design flexibility.

Comparison of Shielding Material Performance

| Feature/Material | Conductive Nylon Composite | Conductive Rubber (Silicone) | Metal Stamped Gasket | Conductive Fabric (Gasket) |

|---|---|---|---|---|

| Molding Complexity | High (Achieves complex shapes) | Medium | Low | Low |

| Weight | Light | Medium | Heavy | Extremely Light |

| Durability | High (Good wear/chemical resistance) | Medium (Prone to compression set) | Extremely High | Low (Prone to wear) |

| Cost (High Volume) | Medium-Low | Medium | Medium-High | Medium |

| Sealing Capability | Good | Excellent | Poor (Requires secondary sealing) | Good |

| Primary Function | EMI Shielding/Structural Support | EMI Shielding/Sealing | EMI Shielding/Grounding | EMI Shielding/Flexible Connection |

Looking to find the perfect EMI solution for your next project? Our injection molding experts can customize the optimal formulation and design for you! contact us

Expansion

In today's environment, where the demands on performance and reliability in electronic devices are constantly increasing, high-performance injection molded nylon washers have become a powerful weapon in tackling EMI challenges. They not only provide the necessary electromagnetic shielding but also meet the stringent requirements of modern design for lightweighting, integration, and cost control. Selecting a professional injection molding partner is a critical step in ensuring washer performance and product reliability. We specialize in the injection molding of high-performance composite materials, dedicated to providing customers with one-stop solutions from material selection to mass production.

1.Injection Process Value: Precision molding ensures uniform dispersion of conductive fillers, guaranteeing stable and consistent EMI shielding effectiveness for every washer.

2.Composite Material Advantage: Professional formulation design balances EMI shielding, mechanical strength, and environmental resistance to meet demanding application requirements.

3.Customization Service: Providing completely customized washer design and manufacturing solutions based on the customer's specific equipment structure and operating frequency.

4.Cost Efficiency: Maximizing commercial value by reducing unit costs while maintaining high performance through efficient molding processes and material optimization.

Conclusion

Injection molded nylon washers, thanks to their composite material modification capability and precision injection molding technology, have become an ideal solution for addressing Electromagnetic Interference (EMI) issues in the electronic and electrical industries. They seamlessly combine high-performance shielding functionality with lightweight design, freedom of design, and cost-effectiveness, providing robust assurance for the reliable operation of new-generation electronic devices. By selecting the appropriate conductive fillers, optimizing the molding process, and conducting rigorous shielding effectiveness testing, we can deliver customized EMI shielding washers for any complex application.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!