Introduction

The watertightness of PVC injection-molded pipes depends not only on the inherent properties of the material but also on the precision of the molding process. From material drying and mold design to process parameter control, every step can determine whether leakage risks occur. In industrial and building drainage systems, consistent sealing performance ensures durability and reduced maintenance costs.

Manufacturers are realizing that watertightness has become a major competitive edge. Adopting precise molding technologies and rigorous testing standards is the key to maintaining consistent quality. This approach not only strengthens brand reliability but also builds lasting customer trust.

How Does Injection Temperature Affect the Sealing of PVC Pipes?

Excessive injection temperature can cause PVC decomposition, leading to gas formation and microvoids that compromise the pipe’s density. Conversely, too low a temperature reduces melt flowability, resulting in incomplete fusion at weld lines. For pipes of varying thickness and diameter, carefully tuned temperature profiles are critical to maintaining watertight performance.

- Temperature Control Calibration: Maintain consistent heating zones to prevent thermal fluctuation.

- Melt Homogenization: Control screw shear rate to ensure even temperature distribution.

- Cooling Time Adjustment: Optimize cooling to minimize internal stress.

- Cavity Insulation Design: Reduce heat loss with insulation layers for better fusion and sealing.

💡 Accurate temperature management is the first safeguard of PVC pipe sealing integrity.

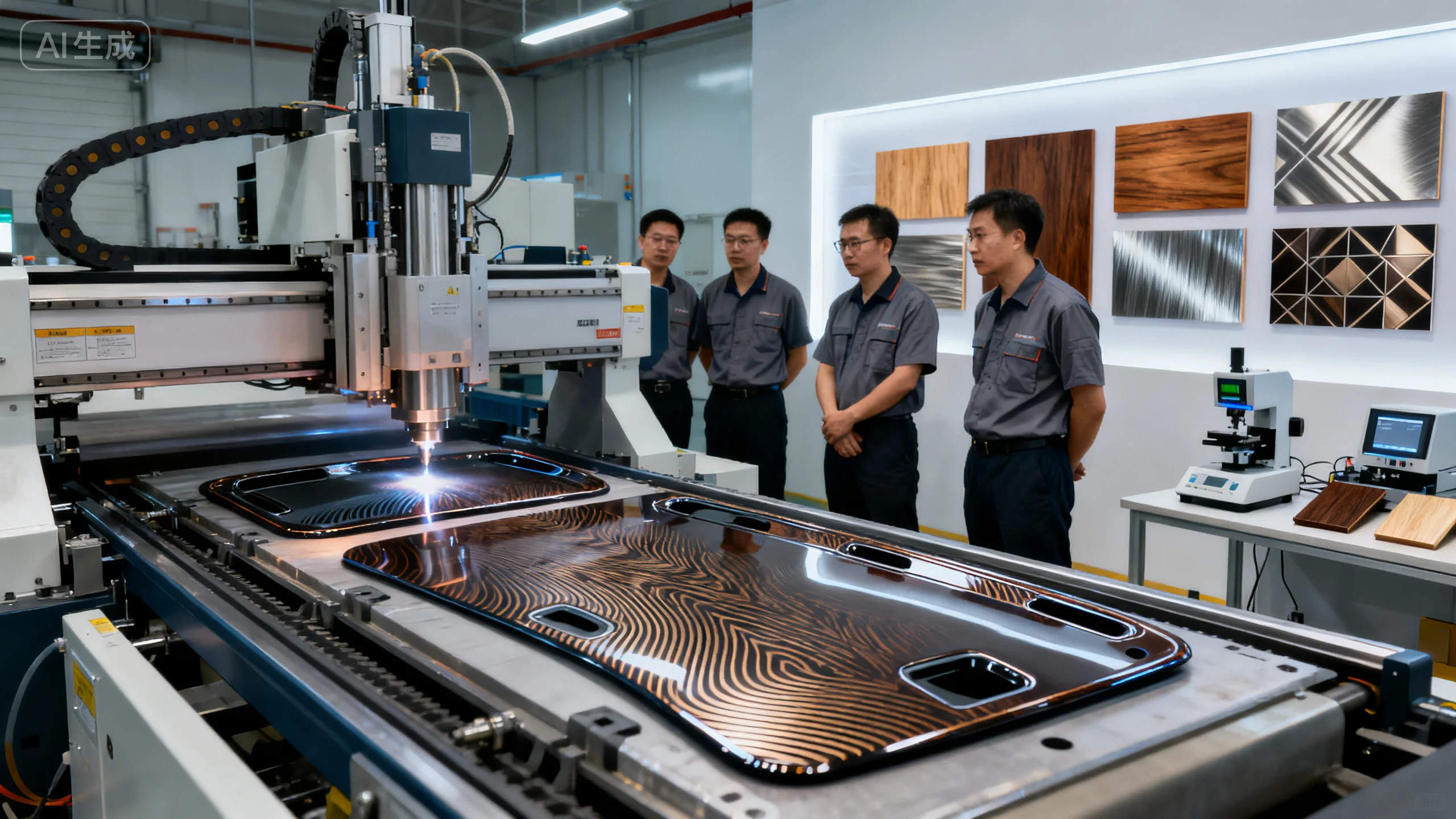

How Can Mold Design Prevent Leakage at PVC Pipe Joints?

The accuracy of the mold determines the geometric precision of PVC pipe joints. Any deviation may prevent the sealing ring from achieving full contact, leading to potential leakage. Optimizing parting surfaces, vent systems, and guiding mechanisms is essential for dimensional consistency.

- Parting Surface Accuracy: Eliminate flash and ensure tight joint fit.

- Seal Groove Optimization: Adjust groove depth and angles to match gasket material.

- Vent Hole Layout: Prevent trapped air from causing voids or surface defects.

- Core Alignment Correction: Reduce assembly errors and ensure inner diameter consistency.

🔧 High-precision mold design provides an invisible but crucial guarantee for watertight performance.

How Can Product Testing Verify the Watertightness of PVC Pipes?

Testing is the final step to ensure watertight performance. Pressure and immersion tests effectively identify hidden leakage points. A standardized testing protocol not only ensures product consistency but also enhances customer confidence in long-term reliability.

- Air Pressure Retention Test: Detect microcracks within the pipe structure.

- Vacuum Seal Testing: Verify resistance against fluid penetration at connection zones.

- Immersion Testing: Evaluate weld line bonding quality and sealing performance.

- Visual and Thickness Inspection: Ensure wall uniformity to prevent weak spots.

🧪 Standardized testing ensures every PVC pipe withstands both pressure and time.

Comparison of Factors Affecting PVC Pipe Watertightness

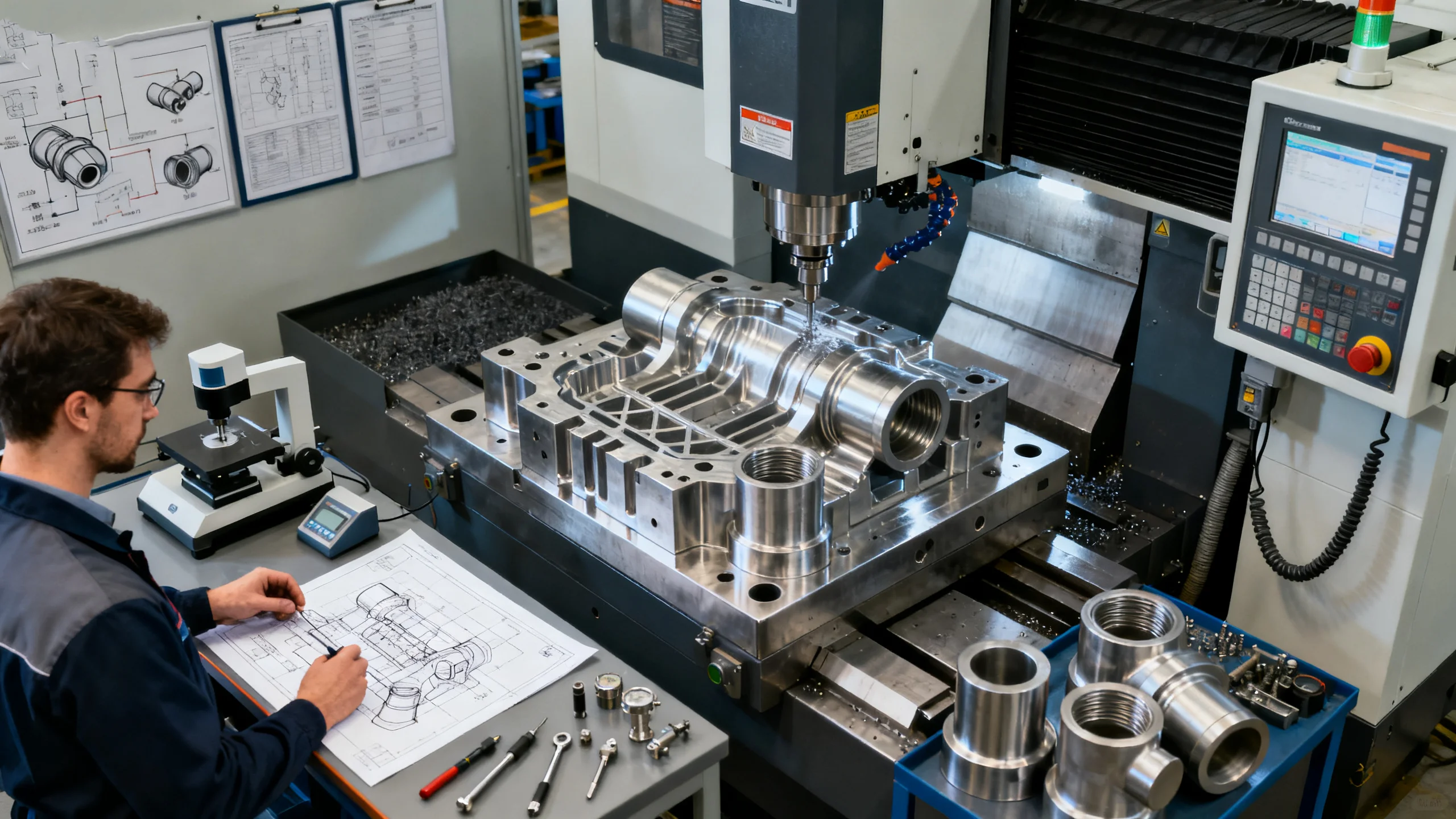

| Factor | Control Method | Impact on Sealing | Production Stage |

|---|---|---|---|

| Temperature Control | Zoned Heating Adjustment | High | Molding |

| Mold Precision | CNC Machining + Calibration | High | Mold Fabrication |

| Material Drying | Controlled Oven System | Medium | Preprocessing |

| Seal Testing | Pressure + Immersion Tests | High | Final Inspection |

Want to improve your PVC pipe molding performance? Reach out now at contact us — our engineering team will tailor a watertight solution for your production line!

Expansion

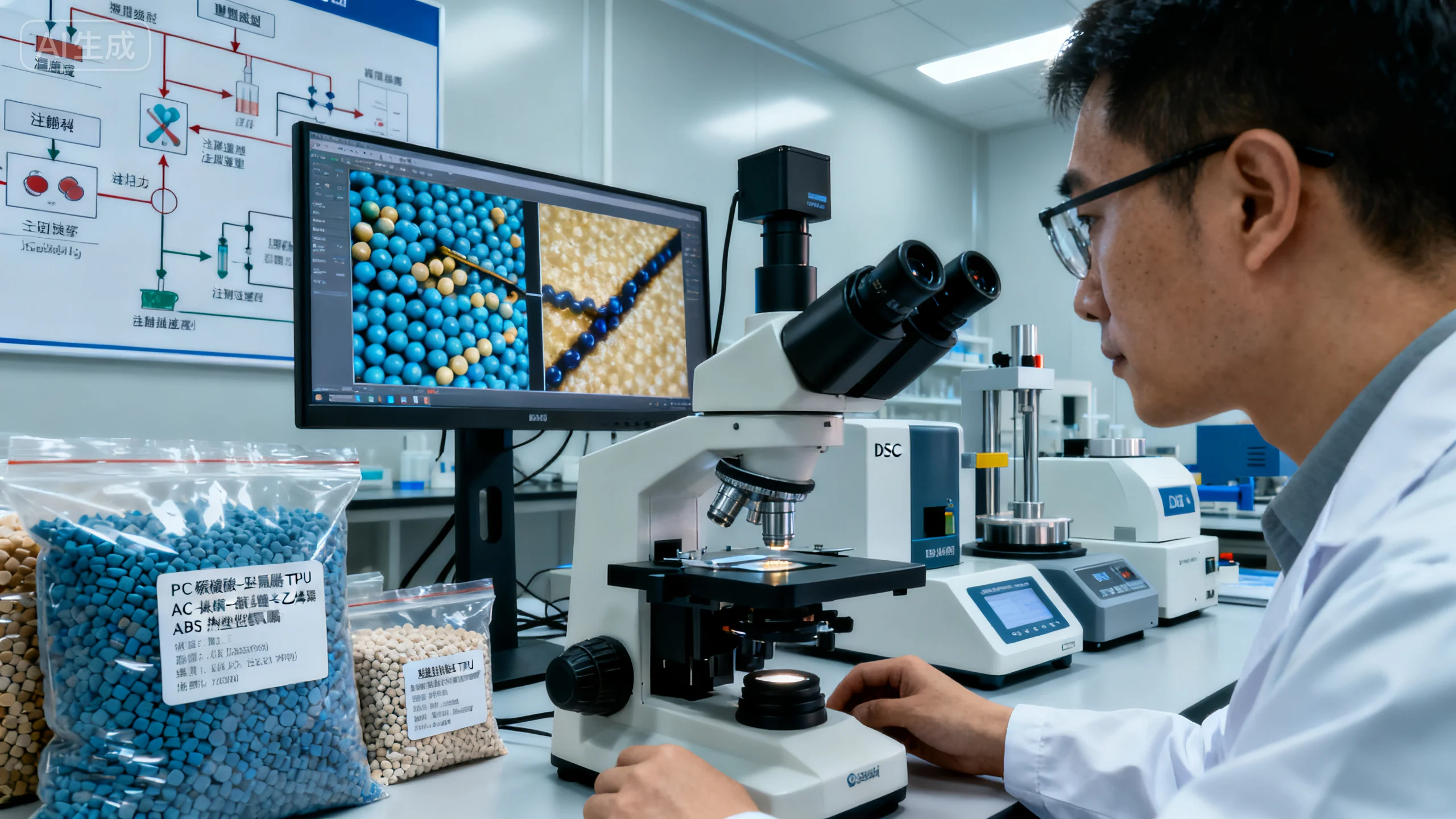

Improving the watertightness of PVC pipes requires a system-level approach rather than isolated adjustments. From molecular control of raw materials to fine-tuned cooling rates, every factor plays a decisive role. With ongoing process optimization and experience accumulation, manufacturers can transform from producing “qualified” products to “high-reliability” products.

1.Material Stability: Use low-volatility PVC compounds with uniform molecular distribution.

2.Process Optimization: Monitor injection pressure and holding time in real time.

3.Mold Maintenance: Regular polishing and inspection of sealing surfaces.

4.Testing System Upgrade: Adopt automated inspection for consistent quality.

Conclusion

Ensuring watertightness in PVC injection-molded pipes defines a company’s core quality standard. Precise process control, accurate mold design, and strict testing form the foundation of a leak-proof system. When watertight performance becomes part of the brand’s promise, it represents not only durability but also technical excellence and trust.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!