Introduction

Nylon parts often suffer from dimensional instability during injection molding, especially when rib design is not optimized, leading to sink marks. Proper rib layout significantly reduces deformation risks while enhancing structural strength.

In industrial applications, the reliability of nylon parts directly impacts assembly precision and product life span. With optimized rib design and process control, shrinkage defects can be minimized, delivering high-quality molded solutions.

How can rib design reduce shrinkage in nylon parts?

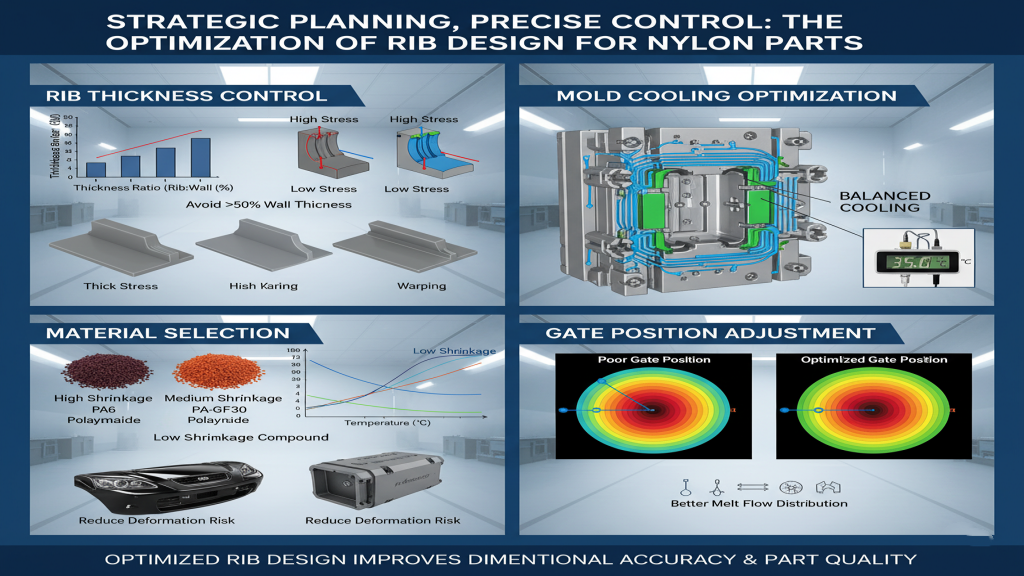

In nylon injection molding, rib thickness, position, and proportion are critical for product stability. Overly thick or thin ribs tend to worsen sink marks, so rib design must align with the material’s flow properties. Applying standardized design principles helps eliminate common surface defects.

- Rib Thickness Control: Rib thickness should not exceed 50% of wall thickness to avoid stress concentration.

- Mold Cooling Optimization: Balanced cooling ensures uniform shrinkage around rib areas.

- Material Selection: Low-shrinkage nylon compounds reduce deformation risks.

- Gate Position Adjustment: Better melt flow distribution minimizes rib-area shrinkage.

😊 Optimized rib design helps reduce sink marks and improves overall part quality.

How to prevent structural warpage caused by nylon ribs?

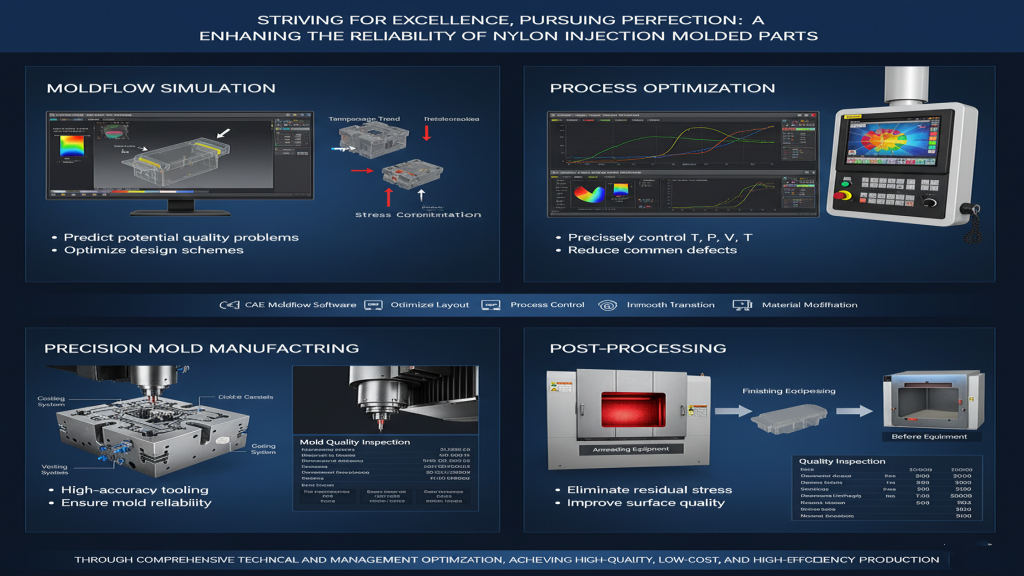

Poor rib design often results in warpage or residual stresses after molding. Balanced rib distribution and thoughtful placement help minimize deformation risks. Precision mold design and process control are equally critical to ensuring dimensional stability.

- Balanced Layout: Avoid excessive ribs on one side to prevent structural imbalance.

- Moldflow Simulation: CAE analysis predicts shrinkage trends before production.

- Fiber Orientation Control: Adjust molding parameters to reduce fiber-induced shrinkage.

- Smooth Rib Transition: Rounded rib-to-wall junctions help reduce stress concentration.

🔧 A balanced rib design significantly lowers deformation issues in nylon parts.

How to optimize rib placement during mold development?

Rib placement strongly affects shrinkage and molding efficiency in nylon products. Aligning rib and gate positions properly reduces sink marks and improves quality. At the same time, uniform cooling within rib areas is essential to achieving dimensional stability.

- Rib-Gate Coordination: Proper alignment avoids flow marks and improves appearance.

- Balanced Cooling Channels: Dedicated cooling near ribs reduces localized shrinkage.

- Smooth Wall Transitions: Natural rib-to-wall transitions help prevent shrinkage concentration.

- Improved Venting: Adequate venting reduces shrinkage and gas marks.

⚙️ Optimized rib placement ensures greater stability and aesthetics in molded parts.

Nylon Rib Design Approaches Compared

| Approach | Thickness Control | Placement Balance | Cooling Uniformity | Shrinkage Risk |

|---|---|---|---|---|

| Standard Thickness | ✅ | ✅ | ✅ | Low |

| Over-Thick Ribs | ❌ | ✅ | ❌ | High |

| Balanced Layout | ✅ | ✅ | ✅ | Low |

| Random Design | ❌ | ❌ | ❌ | High |

Want to know the best rib design for your product? Reach out today contact us for tailored design support!

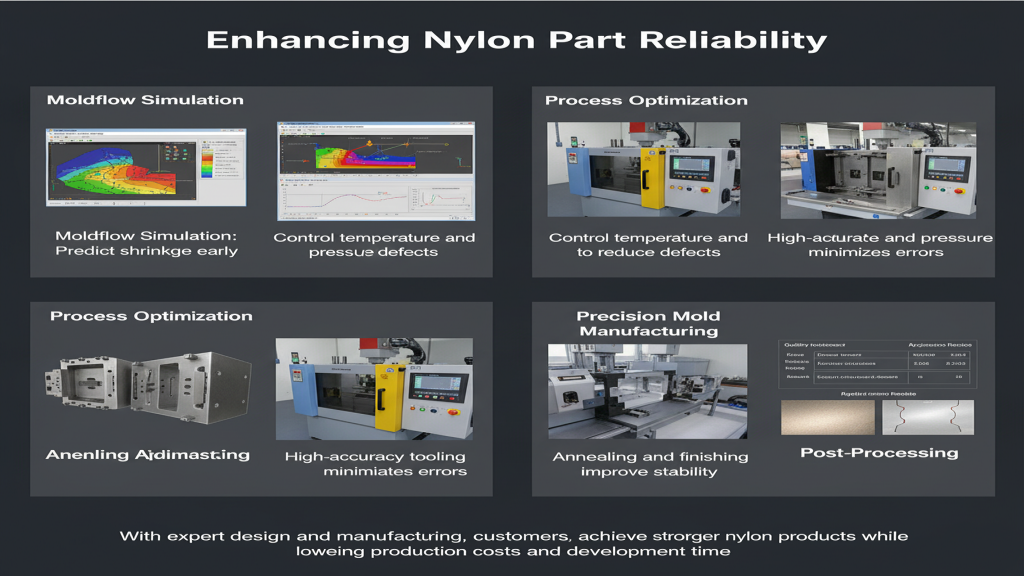

Enhancing Nylon Part Reliability

The quality of nylon molded parts depends not only on material choice but also on mold and process optimization. Advanced moldflow simulation and standardized rib design can proactively prevent shrinkage risks.For different application needs, manufacturers can deliver tailored solutions to ensure both structural strength and aesthetics.

1.Moldflow Simulation: Predict shrinkage early.

2.Process Optimization: Control temperature and pressure to reduce defects.

3.Precision Mold Manufacturing: High-accuracy tooling minimizes errors.

4.Post-Processing: Annealing and finishing improve stability.

Conclusion

In nylon injection molding, rib design is a critical factor influencing product quality. Proper rib thickness, placement, and process settings reduce shrinkage risks and improve overall part reliability.With expert design and manufacturing, customers can achieve stronger nylon products while lowering production costs and development time.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!