Introduction

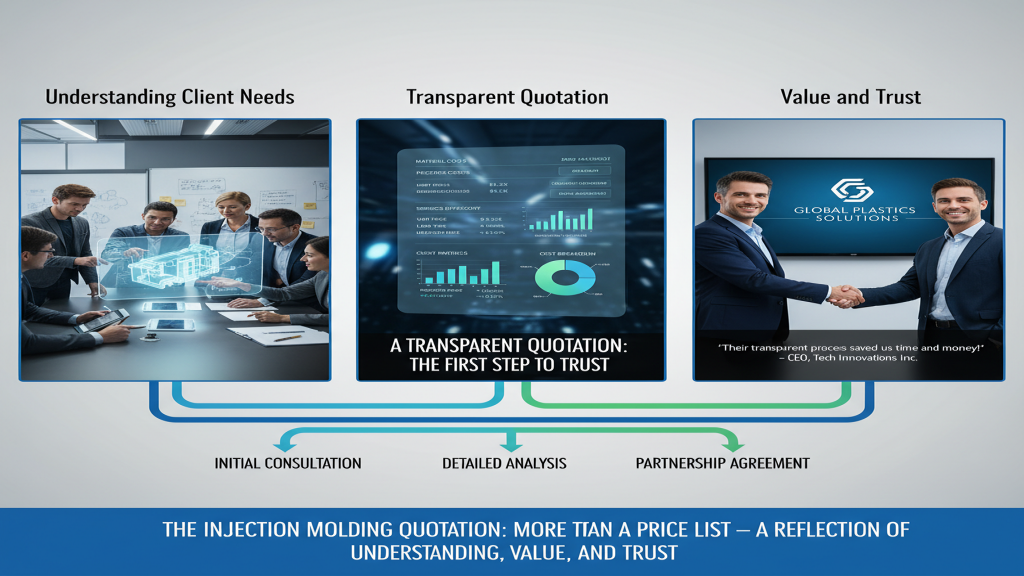

In the injection molding industry, a quotation is not just a price list but a reflection of our understanding of client needs. It clearly presents the match between process, material, and service, enabling clients to assess cooperation value quickly. A transparent quotation is the first step to trust and professionalism.

Beyond data, our quotation also conveys a promise of quality, efficiency, and cost control. Through standardization and detailed presentation, we help clients make faster decisions in a complex market. It is more than a list—it is a safeguard for cooperation.

How does our quotation reflect transparency?

Transparency means every item is open and easy to understand, from raw materials to processing steps. It avoids hidden costs and allows clients to accurately evaluate total budgets. This openness ensures clients can decide with confidence and reduced uncertainty.

- Clear material specification: Material grades and sources are always listed.

- Standardized process: Workflow details are described according to industry standards.

- Cost breakdown: Labor, mold, and processing fees are separated.

- Comparative reference: Directly comparable with common market quotations.

😊 A clear quotation builds trust and confidence in cooperation.

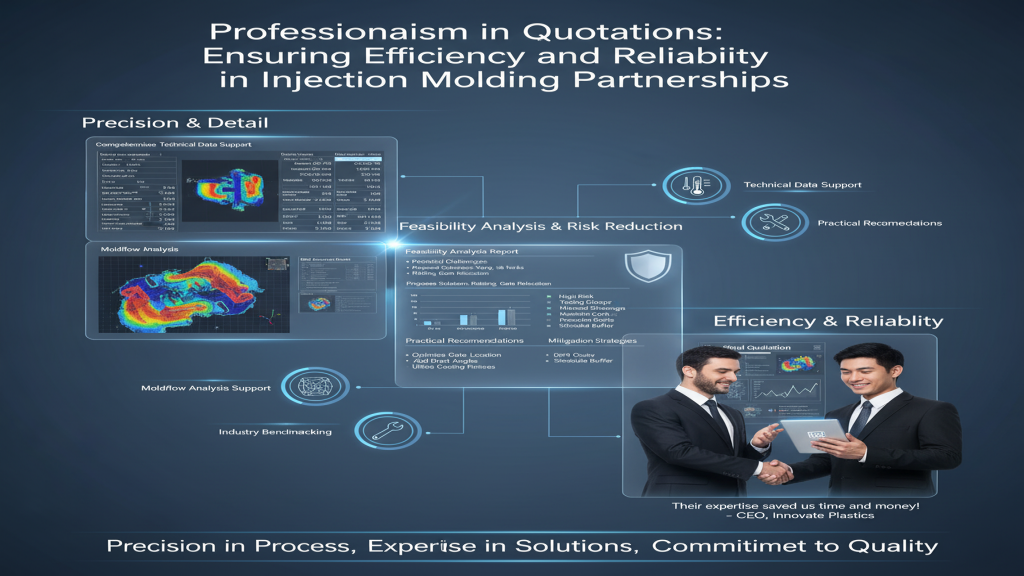

How does our quotation reflect professionalism?

Professionalism is shown in our precision over process and details. We don’t just provide a price—we add process parameters and feasibility analysis. This professional approach reduces risks of later changes and rework.

- Technical data support: Includes molding temperature, pressure, and other parameters.

- Moldflow analysis support: Provides scientific data for design optimization.

- Practical recommendations: Suggestions tailored to project specifics.

- Industry benchmarking: Quotation compared against best practices.

🔧 A professional quotation ensures efficiency and reliability.

How does our quotation reflect added value?

Added value goes beyond numbers—it lies in service and long-term collaboration potential. Through quotations, we convey advantages like after-sales support and supply chain integration. This ensures clients see long-term gains beyond immediate costs.

- After-sales commitment: Covers mold maintenance and process optimization.

- Supply chain integration: Reduces client procurement workload.

- Customization options: Tailored solutions for different industries.

- Long-term cooperation benefits: Flexible terms for bulk orders.

🚀 Our quotation carries not just cost, but sustained value for partnership.

Comparison of Quotation Value Dimensions

| Dimension | Xiamen Ruicheng | Arburg | ENGEL | Milacron |

|---|---|---|---|---|

| Material clarity | High | High | High | Medium |

| Process detail | Comprehensive | Advanced automation | Innovative precision | Broad solutions |

| Added services | Diverse & localized | Sustainability & Industry 4.0 | Digital integration | Post-sale support |

| Long-term value | Strong with client focus | Global reliability | Tech innovation | Established presence |

Why Ruicheng?

Unlike multinational machine makers, Xiamen Ruicheng focuses directly on client-side support, localized service, and flexible cooperation—delivering real advantages in the Chinese and global markets.

How Our Quotation Supports Client Competitiveness

Our quotation is not limited to cost presentation—it is a driving factor for client project success. With precise data and added services, clients can gain higher competitiveness in bidding and mass production. This document becomes an invisible advantage for project success.

1.Save time: Minimizes repeated confirmations.

2.Reduce risks: Avoids omission of key details.

3.Boost decision-making: Helps management finalize faster.

4.Improve project success: Enhances overall competitiveness.

Conclusion

A complete injection molding quotation is more than a price—it is our proactive response to client needs and market challenges. It provides comprehensive support in transparency, professionalism, and added value. Through our quotation, we deliver both assurance and future potential in cooperation.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!