Introduction

HDPE one-stop injection molding solution manufacturers provide customers with a full process service from material selection and mold design to mass production, ensuring smooth project delivery. With advanced equipment and an experienced team, they can quickly respond to diverse customization needs. In a highly competitive market, this all-round service model greatly improves production efficiency and product quality.

Compared with a single service, a one-stop solution not only saves time and cost but also reduces the complexity of communication and collaboration. Customers can complete all stages on the same platform, thus achieving a stable supply chain and faster time-to-market. This allows companies to focus more on market expansion and brand building.

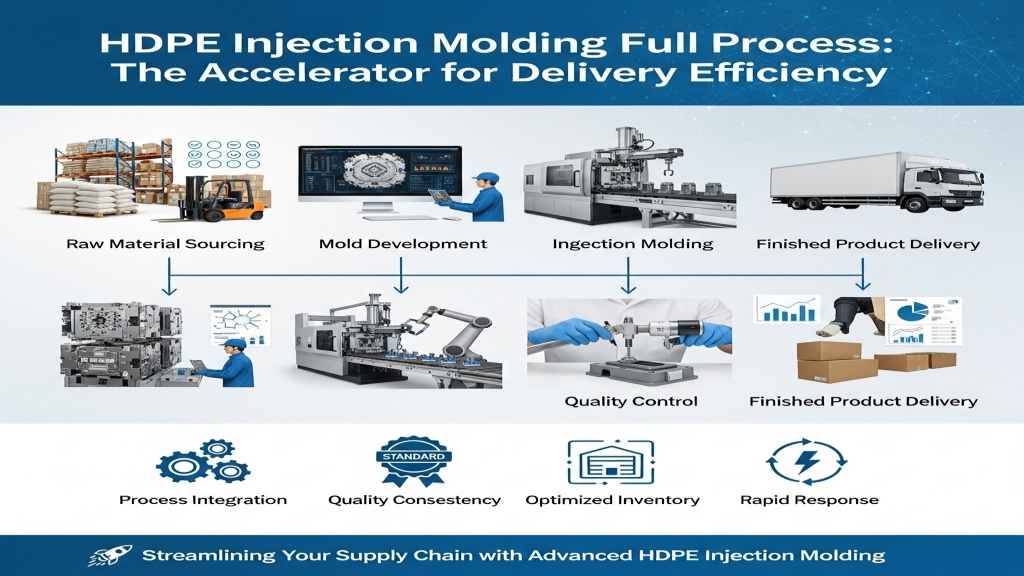

How Does the HDPE Injection Full Process Improve Delivery Efficiency?

HDPE one-stop injection molding manufacturers shorten project delivery cycles by integrating the supply chain and optimizing production processes. Every stage from mold development to finished product delivery is completed within the same system, reducing the time cost of external coordination. This model improves on-time delivery rates for large-volume orders while maintaining consistent quality.

- Process Integration Advantage: Centralized management reduces cross-supplier coordination time.

- Quality Control Consistency: Unified standards ensure batch product uniformity.

- Optimized Inventory Management: Reduce raw material and finished product backlog, lowering capital occupation.

- Improved Response Speed: Quickly adapt to order changes and market demands.

🚀 Full-process mode makes delivery more efficient and stable.

How Does Custom HDPE Molding Ensure Forming Quality?

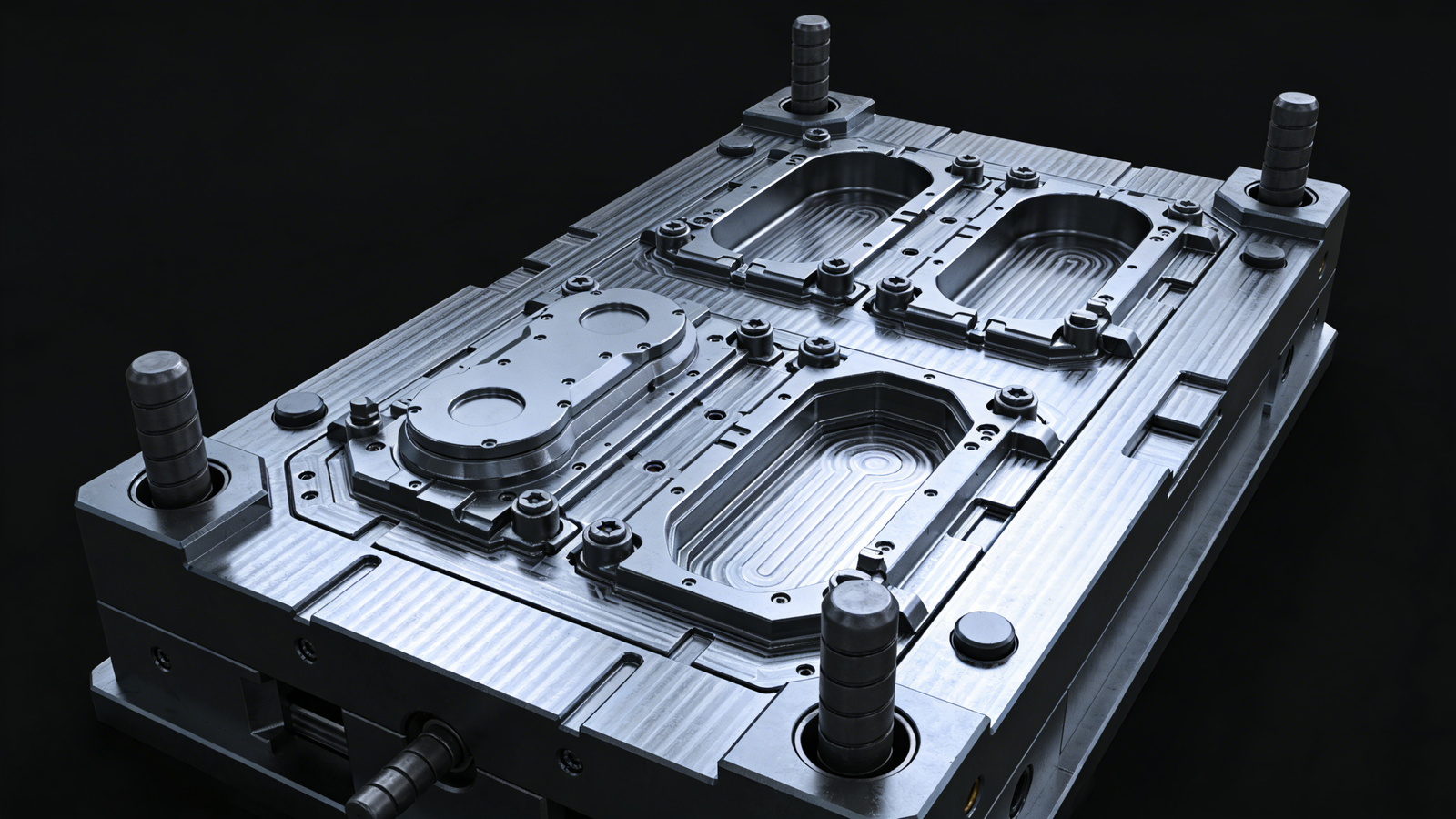

In HDPE injection molding, mold design directly affects the dimensional accuracy and appearance quality of the finished product. Through customized mold solutions, optimal balance between melt flow, cooling efficiency, and demolding process can be ensured. One-stop manufacturers often have in-house mold workshops to enable rapid iteration during design, trial, and improvement stages, reducing defect rates.

- Precision Machining Capability: High-precision processing ensures detail perfection.

- Reasonable Material Selection: Choose the best mold steel and treatment based on HDPE characteristics.

- Optimized Cooling System: Improve molding efficiency and dimensional stability.

- Diverse Surface Treatments: Achieve glossy, textured, or anti-slip effects.

🔧 Custom molds are the core guarantee of product quality.

How to Control Costs in Mass HDPE Injection Production?

HDPE one-stop injection molding manufacturers reduce costs in mass production through process optimization and resource integration. Precise material usage control, automated production equipment, and standardized operations collectively reduce waste and labor expenses. These measures maximize profit margins while ensuring product performance.

- Automated Production Line: Reduce labor dependence and improve efficiency.

- Bulk Raw Material Purchasing: Centralized procurement lowers unit price.

- Waste Recycling: Reuse to reduce production costs.

- Standardized Production Processes: Minimize rework and defect rates.

💰 Efficient production means lower costs and higher profits.

HDPE Injection Solution Type Comparison

| Solution Type | Cost Control | Quality Stability | Delivery Speed | Customization Level |

|---|---|---|---|---|

| One-Stop Full Process | High | High | Fast | High |

| Single Processing Stage | Medium | Medium | Medium | Medium |

| Outsourced Multi-Supply | Low | Medium | Slow | Medium |

| Traditional Segmented | Medium | Low | Slow | Low |

Advantages of Working with One-Stop Manufacturers

Working with HDPE one-stop injection molding manufacturers reduces supply chain risks and increases project execution flexibility. They can find the optimal balance between technology, cost, and delivery time, helping clients stay ahead in fierce competition. During the entire project cycle, supplier collaboration and technical support are key to achieving goals.

1.Centralized Supply Chain: Reduce external coordination risks.

2.Transparent Costs: Better budget control.

3.Continuous Technology Optimization: Maintain product competitiveness.

4.Predictable Delivery Times: Ensure market timing accuracy.

Conclusion

HDPE one-stop injection molding solutions bring integrated advantages in production efficiency, quality assurance, and cost control. It is not only a production model choice but also an important part of a competitive strategy. In a rapidly changing market environment, this model helps companies reduce trial-and-error costs and accelerate product launches. Choosing the right partner will directly impact business growth and brand image.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!