Introduction

In composite material processing, RTM (Resin Transfer Molding) and injection molding each excel in specific domains due to differences in material characteristics, production volume, and mold investment.RTM shows higher adaptability in low-volume, high-strength applications.

On the other hand, injection molding outperforms in automation, repeatable accuracy, and unit cost control.With advancements in mold technology and rapid changeover, injection molding continues to expand its applicability.

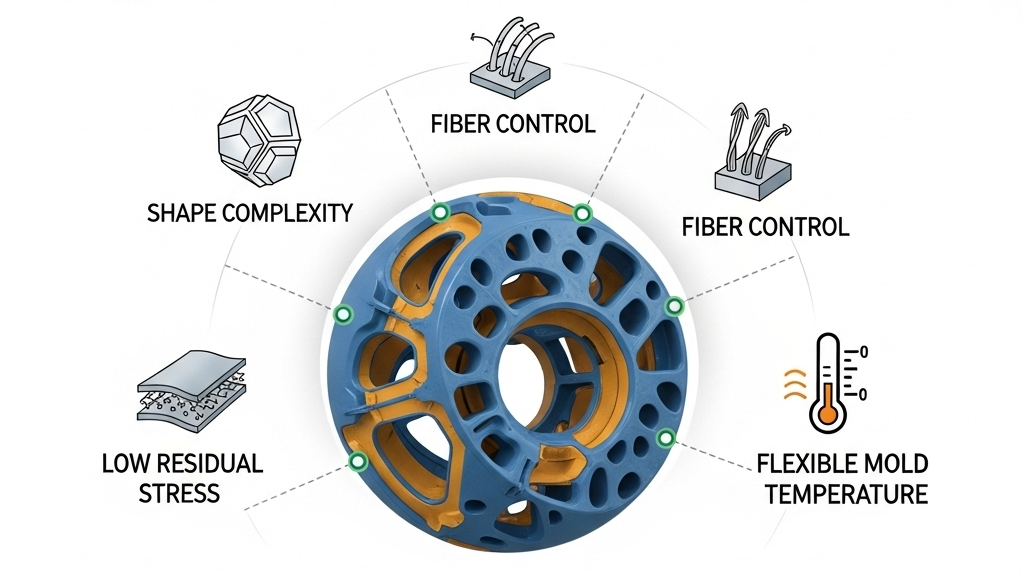

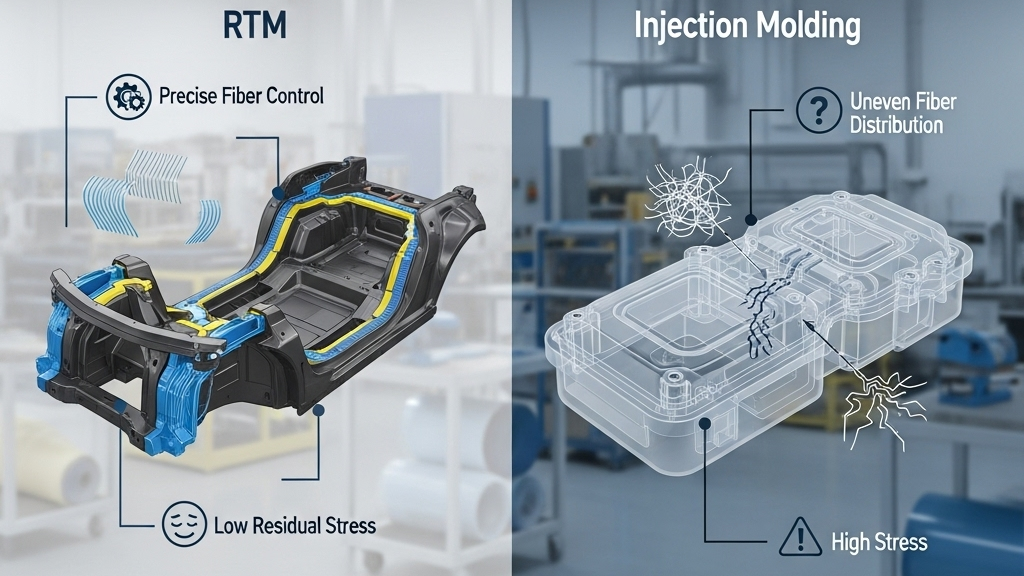

Is RTM More Suitable for Complex Structures?

Due to its low-pressure forming, RTM can better fill complex cavities and wrap fiber structures, ideal for composite parts requiring precise fiber orientation.This delivers enhanced structural integrity for applications like automotive frames and wind turbine blades.

- Shape Complexity: Ideal for complex shapes with fiber reinforcement.

- Fiber Control: Enables accurate control over fiber direction and layering.

- Low Residual Stress: Low-pressure molding results in stable parts.

- Flexible Mold Temperature: Supports diverse thermoset resin systems.

🎯 Complex shapes favor RTM for its structural flexibility

Is Injection Molding Better in Output and Speed?

Injection molding uses high-speed injection and fast cooling cycles to produce parts at high throughput.It is irreplaceable in standardized, automated mass production.

- Batch Efficiency: Supports daily outputs in the tens of thousands.

- Short Cycle Time: Each mold cycle completes in seconds.

- High Automation: Integrated with robotic arms and automated temperature systems.

- Multi-Cavity Design: Simultaneous molding of multiple parts boosts output.

🚀 Injection molding is built for speed and high-volume production

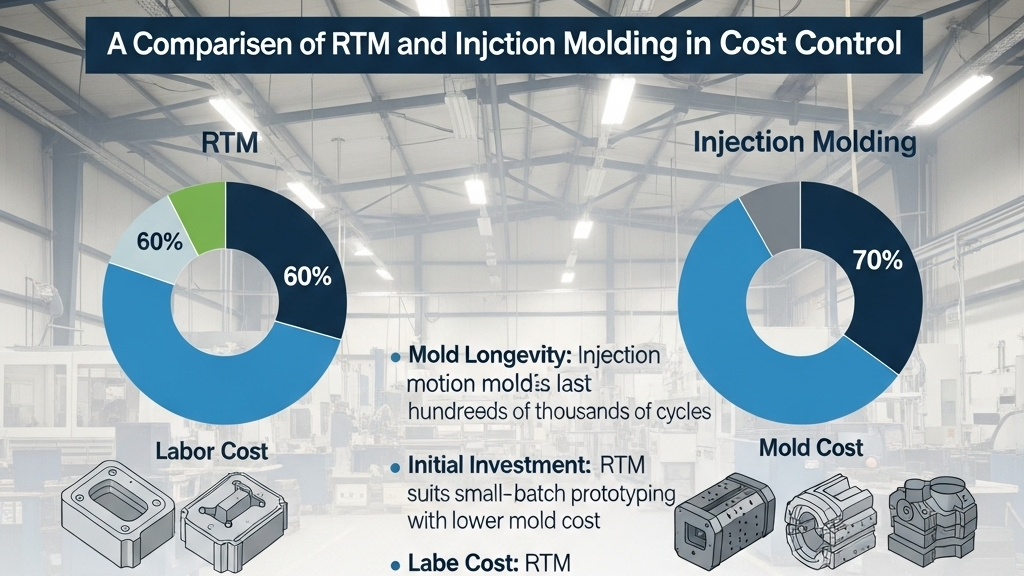

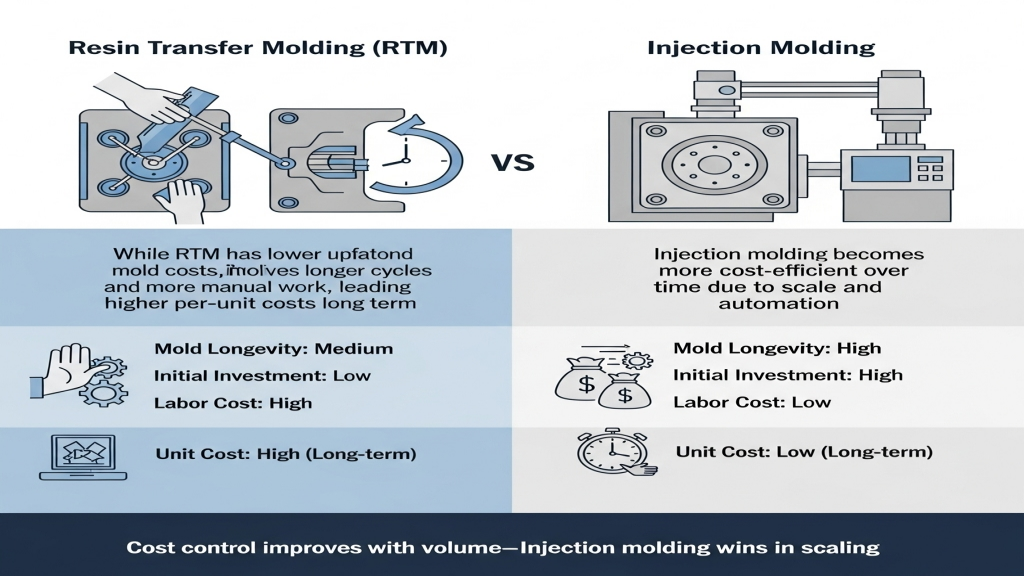

Which Process Offers Better Cost Control?

While RTM has lower upfront mold costs, it involves longer cycles and more manual work, leading to higher per-unit costs long-term.Injection molding becomes more cost-efficient over time due to scale and automation.

- Mold Longevity: Injection molds last hundreds of thousands of cycles.

- Initial Investment: RTM suits small-batch prototyping with lower mold cost.

- Labor Cost: RTM requires manual fiber layup; injection is mostly automated.

- Unit Cost: Large volumes drastically reduce injection molding cost.

💰 Cost control improves with volume—Injection molding wins in scaling

RTM vs Injection Molding

| Parameter | RTM | Injection Molding |

|---|---|---|

| Mold Cost | Low (good for customization) | High (suitable for large runs) |

| Cycle Time | Minutes to tens of minutes | Seconds to less than a minute |

| Automation | Medium (manual layup) | High (automated process) |

| Material Types | Mostly thermoset resins | Mostly thermoplastics |

| Part Precision | Moderate (fiber layout impact) | High (precise mold control) |

| Complex Structures | Good (fiber wrapping possible) | Average (wall thickness limits) |

| Post-processing | Demolding and trimming needed | Often ready for use |

| Unit Cost | Medium-High | Low in mass production |

Expansion

In sectors like aerospace and railway, where lightweight structure is crucial, RTM delivers excellent performance.In contrast, injection molding is the preferred method in consumer electronics, appliances, and auto interiors where consistency and speed matter most.The key lies in defining the application needs and matching the right process accordingly.

1.Application Segmentation: Each method suits a different market.

2.Processing Window: RTM uses narrow thermoset ranges, while injection molding handles wider thermoplastics.

3.Environmental Trends: Injection molding supports recyclability; RTM enables structural optimization.

4.Labor vs Automation: The level of automation dictates long-term cost structure.

Conclusion

RTM and injection molding are not rivals but complementary systems, each optimized for different production logics and business models.The better method depends on what you are producing.As technology evolves, both methods may integrate further, enabling new hybrid manufacturing possibilities.Understanding the core traits of each helps you make the most commercially viable decision.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!