Introduction

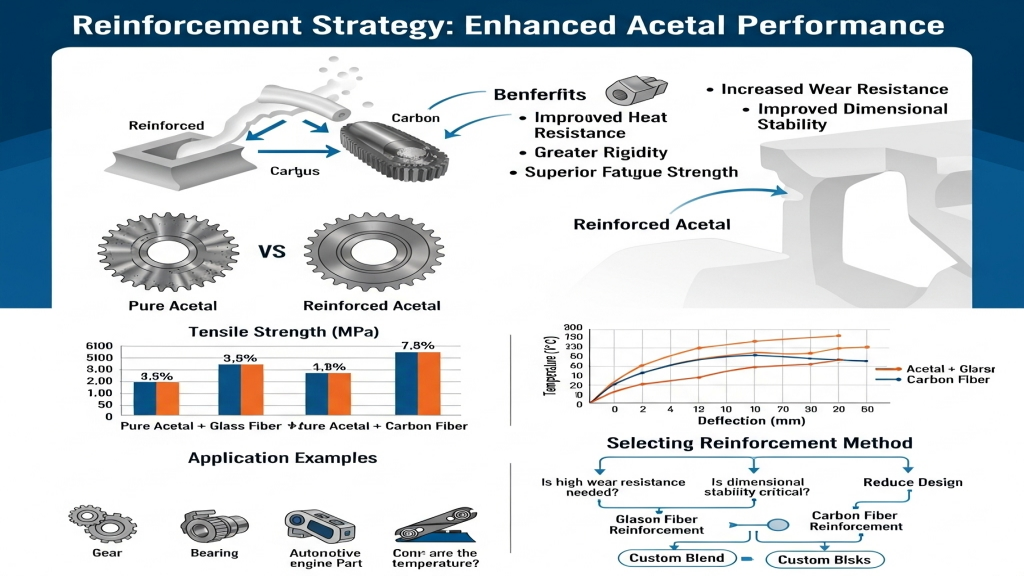

Acetal, as one of the engineering plastics, offers excellent wear resistance and dimensional stability. With the addition of glass fiber or carbon fiber, its structural performance and molding adaptability are significantly enhanced. This type of reinforcement has become a key solution for improving cost-performance ratio in functional injection parts.

The reinforced Acetal shows marked improvements in heat resistance, rigidity, and fatigue strength. Whether in high-load moving parts or lightweight structural components, this modified formula provides an optimized choice. Selecting the right reinforcement method is critical in reducing design failure risks.

Does adding glass fiber improve strength and dimensional stability?

As a rigid filler, glass fiber significantly enhances the tensile and flexural strength of Acetal, while also reducing creep under high temperatures. In complex-shaped parts, glass-filled Acetal maintains better dimensional accuracy.

- Mechanical Enhancement: Tensile and flexural strength nearly double

- Thermal Control: HDT increases by 10–15°C

- Dimensional Stability: Shrinkage rate decreases, better product consistency

- Molding Adaptability: Good demolding behavior during injection molding

🔍 Glass-filled Acetal delivers both high strength and high precision.

Does carbon fiber affect conductivity and stiffness?

Carbon fiber not only enhances the rigidity of Acetal, but also imparts a certain degree of electrical conductivity, making it suitable for static-dissipative applications. Compared to glass fiber, carbon-filled Acetal is more ideal for lightweight and anti-static components.

- Weight Reduction: Lower density, lighter parts

- Conductive Performance: Surface resistivity below 10⁶Ω possible

- Mechanical Stiffness: Higher modulus, ideal for thin-walled, high-load parts

- Thermal Behavior: Faster heat transfer, but local heating must be controlled

⚙️ Carbon-filled Acetal is ideal for high-performance electronics and sporting parts.

Does fiber addition affect flowability and mold life?

Reinforced Acetal tends to have slightly lower flowability, and the abrasive nature of glass or carbon fibers can wear molds. Optimizing runner design and mold surface treatment is key to maintaining production efficiency.

- Flow Control: Higher injection pressure or temperature may be required

- Mold Material Suggestion: Hardened steel or surface coatings are recommended

- Fiber Orientation Issues: Warpage or stress concentrations may occur

- Demolding Strategy: Larger draft angles recommended to protect mold surfaces

🛠️ Fiber-reinforced Acetal demands optimized tooling and molding processes.

Performance Comparison Table: Pre- and Post-Reinforcement Acetal

| Property | Virgin Acetal | Glass-Filled Acetal | Carbon-Filled Acetal | Commercially Modified Acetal |

|---|---|---|---|---|

| Tensile Strength (MPa) | 65 | 110 | 105 | 90 |

| Flexural Modulus (MPa) | 2500 | 5000 | 5500 | 4300 |

| Shrinkage Rate (%) | 2.0 | 0.8 | 0.9 | 1.2 |

| HDT (°C) | 110 | 125 | 130 | 120 |

| Flowability | Excellent | Medium | Medium | Medium-High |

| Coefficient of Friction | Low | Medium | Medium | Low |

| Electrical Conductivity | None | None | Yes | Optional |

| Cost Index | 1.0 | 1.5 | 1.8 | 1.6 |

Expansion

Reinforcing Acetal with fibers is not just about performance—it extends business possibilities. As client demands diversify in terms of accuracy, strength, weight, and cost, material customization becomes increasingly important.

1.Multi-Industry Expansion: Reinforced Acetal enables high-end applications

2.Client Customization Support: One-stop service from formulation to tooling

3.International Certifications: Quality assurance across all orders

4.Long-Term Cooperation: Strategic partnership to reduce cost and boost efficiency

Conclusion

Glass or carbon fiber reinforced Acetal is rapidly becoming a go-to material in high-performance injection molding. It excels in strength, precision, and heat resistance, while adapting to challenging conditions. However, it also calls for experienced tooling and processing teams to fully unlock its value.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!