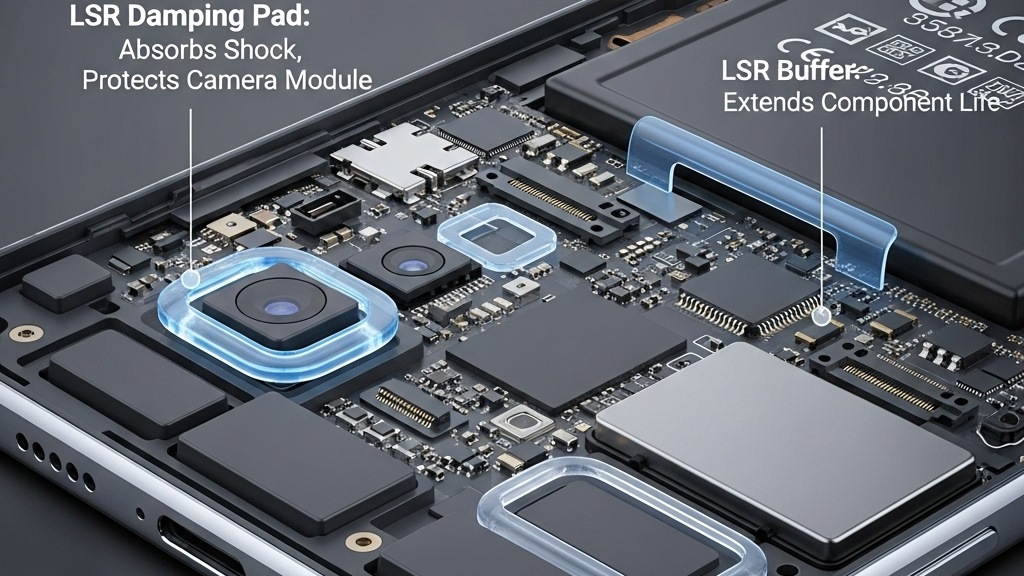

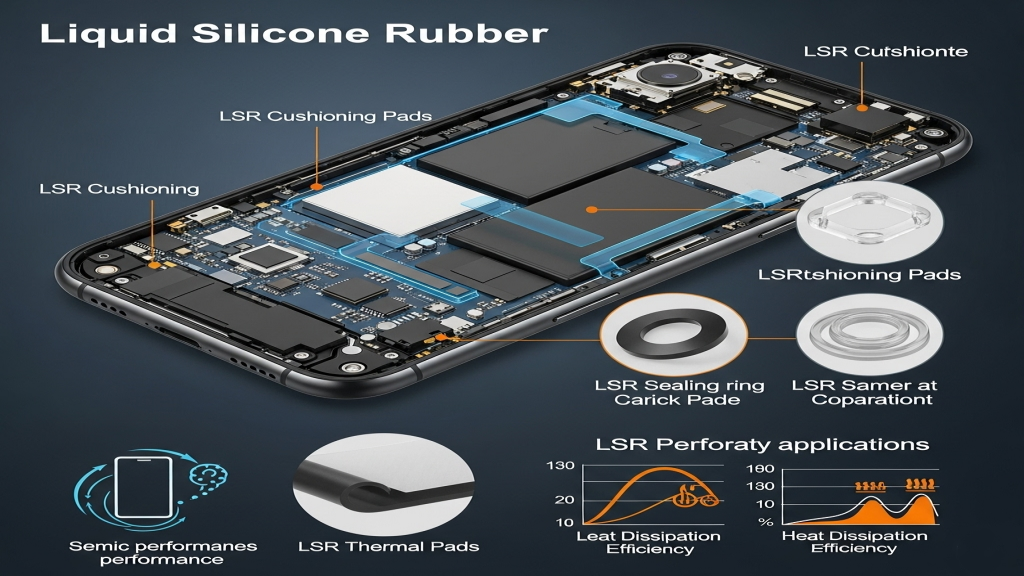

Liquid Silicone Rubber (LSR) is playing a vital role in the damping systems of modern electronics due to its outstanding elasticity and fatigue resistance. Especially in premium consumer electronics, LSR cushions impact, extends component life, and reduces maintenance. It has become an indispensable functional part in electronic products.

As electronics become thinner and more precise, the demand for advanced damping materials increases. The high fluidity of LSR and compatibility with high-precision injection molding processes allow for complex insert molding. This offers highly integrated and reliable solutions for high-end electronics manufacturing.

How Does LSR Improve Electronic Product Performance?

LSR components have excellent rebound and low compression set, making them ideal structural damping materials. It not only improves shock resistance but also enhances the overall user experience.

- Structural Protection: Reduces component damage during drops or vibrations.

- Thermal Conduction: Aids in dissipating heat from modules to prevent thermal damage.

- Lightweight Integration: Simplifies assembly and improves consistency.

- High Fatigue Resistance: Maintains stability under long-term repeated use.

How Does Injection Molding Influence LSR Performance?

High-performance LSR damping parts rely on precise injection molding control. Mold design, injection uniformity, and cure time directly affect product performance. Consistency in molding determines the functional effectiveness of LSR damping components.

- Mold Design Optimization: Enhances molding efficiency and reduces bubbles or stress.

- Automation Improves Efficiency: Automated systems increase yield and throughput.

- Accurate Temperature Control: Ensures full crosslinking and stable output.

- Mature Demolding Mechanism: Suited for high-frequency cycles with minimal surface defects.

Which Electronics Sectors Benefit from LSR Damping?

LSR's flexibility and durability make it ideal for sectors like wearables, portables, and telecom. Diverse product shock-resistance demands drive the wide application of LSR damping structures.

- Wearables: Used in bands, sensor housing, and internal buffers.

- Small Appliances: Reduces vibration from motors or switching operations.

- Telecom Devices: Maintains signal integrity with structural support.

- Audio Equipment: Enhances speaker damping and sound insulation.

Comparison of LSR vs. Common Damping Materials

| Feature | LSR Silicone | TPE Elastomer | PU Polyurethane | Rubber Materials |

|---|---|---|---|---|

| Compression Set | Excellent | Moderate | Good | Poor |

| Heat Resistance | High (-50~200°C) | Medium (-20~120°C) | Average | Average |

| Process Stability | High | Medium | Low | Low |

| Electronic Compatibility | High | Moderate | Moderate | Low |

| Precision Molding | High Precision | Average | Poor | Poor |

| Product Life | Long | Medium | Medium | Short |

| Cost Efficiency | Medium | High | High | High |

| Eco-Friendliness | Excellent | Moderate | Poor | Poor |

How Does LSR Enhance Product Competitiveness

As an innovative damping material, LSR meets functional needs and aligns with eco-friendly trends. Its durability and design flexibility make it stand out in a saturated market. Especially with smart manufacturing, LSR enables modular integration for creative product design.

1.Brand Value Boost: LSR enhances product quality and perceived reliability.

2.Lower After-Sales Cost: High fatigue resistance reduces failure rates.

3.Product Differentiation: Unique injection potential enables design innovation.

4.Environmental Compliance: LSR meets global environmental regulations.

Conclusion

LSR damping components are now key to structural integration in modern electronics. Their performance, cost-effectiveness, and sustainability make them a holistic solution. Through precise injection molding, LSR materials offer significant commercial and competitive value. As electronics evolve, LSR applications will continue expanding into smarter, more efficient product lines.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!