As a high-performance engineering plastic, Nylon (PA) is widely used in the injection molding field. However, accurately balancing its inherent high strength with the necessary flexibility is the core challenge faced by engineers. This not only involves material selection but also relies on precise control of the injection molding process. This article will explore the key strategies for achieving the optimal balance of strength and flexibility in nylon injection molding.

Material selection is fundamental, but the injection molding process profoundly affects the performance of nylon. The final mechanical properties of the product, especially the balance of strength and flexibility, largely depend on the thermal history and cooling rate during the injection molding process, which directly affects crystallinity. High crystallinity enhances strength but may sacrifice toughness, while the opposite increases flexibility but reduces strength. Therefore, precisely controlling process parameters is key to unlocking the potential of nylon.

The Relationship Between Nylon Structure and Mechanical Properties

The macroscopic mechanical properties of nylon materials, such as strength and flexibility, are rooted in their unique molecular structure. The regular arrangement and interaction of polyamide segments directly determine the crystallization behavior of the material.

- Hydrogen Bonds and Strength: Hydrogen bonds between nylon molecular chains are the core forces that provide high strength, and their presence directly affects the stiffness of the material.

- Crystallinity and Performance: The performance balance of nylon materials depends on their crystallinity. Crystalline regions provide strength and rigidity, while amorphous regions provide flexibility.

- Crystal Size and Toughness: By controlling the crystal size, the toughness performance of nylon can be further fine-tuned. Small crystals can usually improve the impact resistance of the material.

- Key to Process Control: Understanding and precisely controlling the crystallization behavior of nylon is the fundamental way to achieve a balance between the strength and flexibility of the product.

How to Control the Mechanical Properties of Nylon Through Injection Molding?

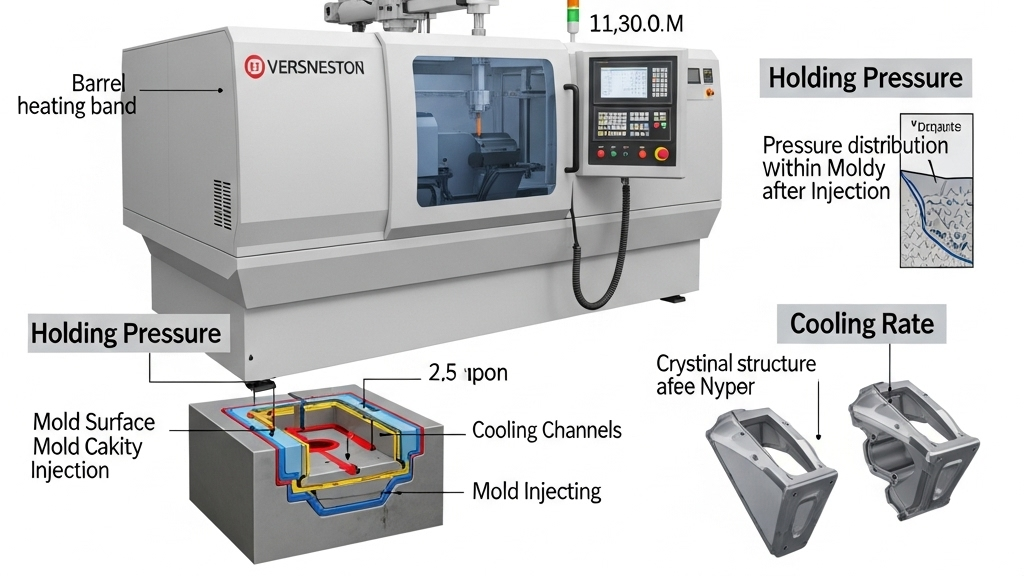

The parameter settings during the nylon injection molding process directly shape the final properties of the material. By precisely controlling key process variables, we can effectively control the strength and flexibility of nylon parts.

- Melt and Injection: Precisely controlling the melt temperature and injection speed can optimize the molecular orientation and crystallization process of nylon, affecting the final mechanical properties.

- Mold Temperature: Mold temperature is key to controlling the crystallinity and crystal size of nylon, directly determining the strength and flexibility ratio of the product.

- Holding Pressure Strategy: Appropriate holding pressure and holding time can ensure the density of the product, affecting internal stress and overall strength performance.

- Cooling Rate: The cooling rate directly affects the crystalline morphology of nylon. Rapid cooling tends to increase flexibility, while slow cooling increases strength.

How Does Nylon Modification Improve Overall Performance?

In addition to the fine control of the injection molding process, innovation in the field of materials science has also opened up new avenues for improving nylon performance. By introducing various modification strategies, we can significantly broaden the application boundaries of nylon materials without sacrificing processability.

- Fiber Reinforcement: Adding glass fiber or carbon fiber can significantly improve the strength, rigidity, and heat resistance of nylon while maintaining good processability.

- Toughening Agent Application: Adding elastomer toughening agents can effectively improve the flexibility and impact toughness of nylon, optimizing performance while maintaining strength.

- Nanomaterial Composites: Introducing nanofillers can comprehensively improve the mechanical properties of nylon. Even small additions can produce significant effects without impairing processability.

- Copolymerization and Blending: By copolymerizing nylon or blending it with other polymers, the molecular structure and crystallization behavior can be adjusted, thereby balancing and improving overall performance.

Key to nylon injection molding

| Control Dimension | Influencing Factor/Method | Leaning Towards Strength (Enhancement) | Leaning Towards Flexibility (Enhancement) | Notes |

|---|---|---|---|---|

| Material Intrinsic Properties | Crystallization Behavior | High crystallinity, large crystals | Low crystallinity, small crystals | Nylon grade selection is fundamental |

| Injection Molding Process Control | Mold Temperature | Higher mold temp for larger crystals | Lower mold temp for smaller crystals/amorphous regions | Directly impacts crystallization morphology |

| Material Modification Methods | Fiber Reinforcement | Glass/Carbon fiber significantly enhances | - | Suitable for high rigidity demands |

| Toughener Addition | - | Elastomers (e.g., POE, SEBS) | Significantly improves impact resistance |

Strength and Flexibility of Nylon Products

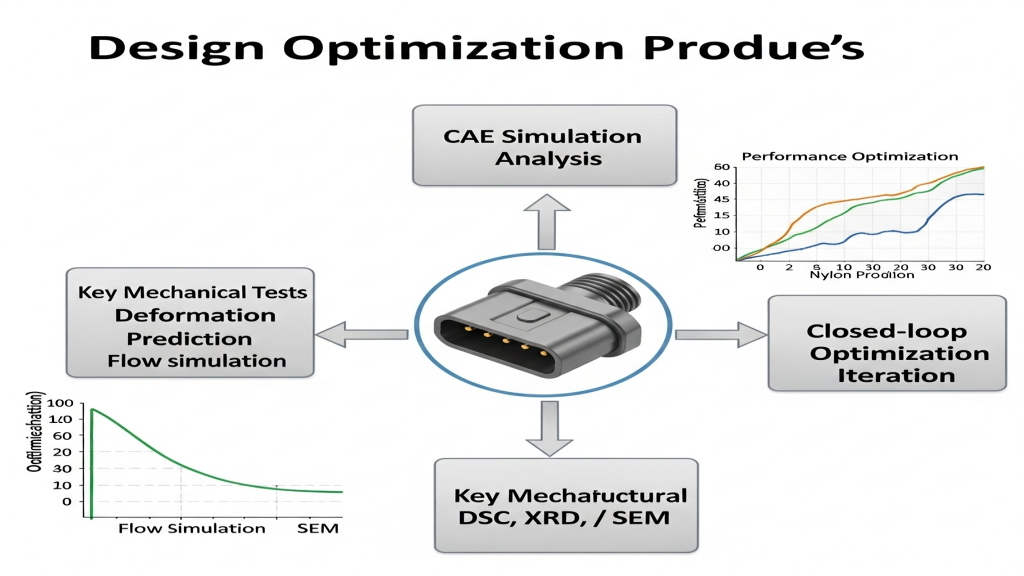

In the development of high-performance nylon products, relying solely on theoretical knowledge and experience adjustment is insufficient. To ensure that the product achieves the expected balance of strength and flexibility, early simulation analysis and rigorous post-testing have become the two pillars of verifying and optimizing the design. These engineering practices can provide data support, guide design iterations, and ultimately achieve excellent product performance.

1.CAE Simulation Analysis: Using CAE tools to predict the stress, strain, and flow behavior of the product under stress during the injection molding process, thereby guiding design optimization.

2.Key Mechanical Tests: Directly assess the strength, modulus, and toughness of the product through tensile, impact, and flexural tests, verifying performance.

3.Microstructural Characterization: Using techniques such as DSC, XRD, and SEM to analyze crystallinity and crystal morphology, explaining and optimizing macroscopic properties from a microscopic level.

4.Closed-Loop Optimization Iteration: Combine simulation and test data to continuously adjust design, materials, and processes to achieve the best balance of nylon product performance.

Conclusion

Nylon injection molded parts rely on a deep understanding of the molecular structure and crystallization behavior of nylon, as well as the application of material modification strategies. By using early simulation analysis to predict problems and combining post-testing with mechanical tests and microstructural characterization to verify the effects, a closed-loop optimization iteration process is formed. This comprehensive strategy is key to ensuring that nylon products achieve the ideal balance of strength and flexibility in practical applications.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!