The stability of large injection molded parts is of utmost importance, and material selection is critical. ABS and PLA are common injection molding materials with distinct characteristics. For large parts, which material is more stable? This article will provide a basis for material selection through professional analysis and comparison of mechanical properties, environmental adaptability, and long-term performance.

Basic characteristics of ABS and PLA. Both have their advantages in the injection molding field. However, large injection molded parts have higher stability requirements. Next, we will focus on analyzing the mechanical behavior of materials under long-term loads, sensitivity to the environment, and potential deformation problems, and deeply compare the stability differences between ABS and PLA in large applications.

ABS vs PLA Which is Stronger?

From the perspective of basic mechanical properties, ABS and PLA exhibit significant differences in tensile strength, flexural modulus, and impact strength. These differences directly affect their performance when subjected to various stresses that large injection molded parts may encounter. Understanding the initial mechanical characteristics of these two materials is the primary step in assessing their stability in practical applications.

- Tensile Strength: PLA typically exhibits higher tensile strength, making it more resistant to tensile stress.

- Flexural Modulus: PLA has a higher flexural modulus, meaning it has better rigidity and is more resistant to bending deformation.

- Impact Strength: ABS generally has higher impact strength, making it less prone to fracture when facing sudden impact loads.

- Comprehensive Consideration: For large injection molded parts, if they mainly bear static loads or require extremely high dimensional stability, PLA may be more stable. However, if the parts are susceptible to impact or require some flexibility, ABS may offer greater stability.

Who Can Maintain Stability Better?

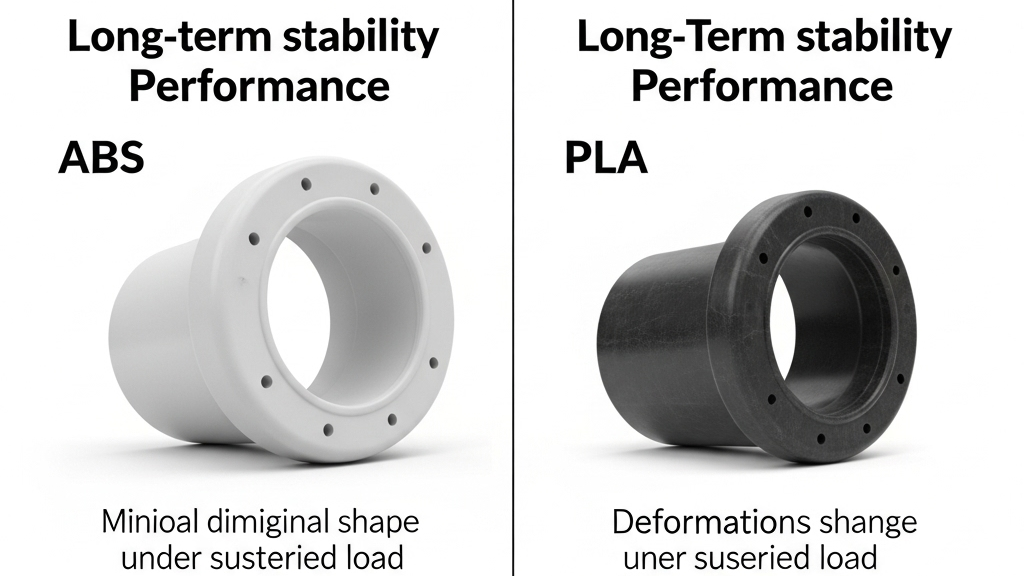

The long-term service performance of large injection molded parts is a key aspect of assessing material stability, and creep resistance, dimensional stability, and tolerance to environmental factors directly affect the long-lasting reliability of components. Examining the differences between ABS and PLA in these three aspects helps us predict and evaluate their performance degradation and deformation trends during long-term use.

- Creep Resistance: ABS is more resistant to slow deformation under long-term loads, exhibiting superior creep resistance.

- Dimensional Stability: ABS is insensitive to temperature changes and humidity, and usually maintains better long-term dimensional stability.

- Temperature Resistance: ABS typically has a higher upper temperature limit and can be used stably in a wider temperature range.

- Moisture Resistance: ABS has low moisture absorption, and is better able to maintain the stability of its performance and dimensions in humid environments.

What are the Stability Issues?

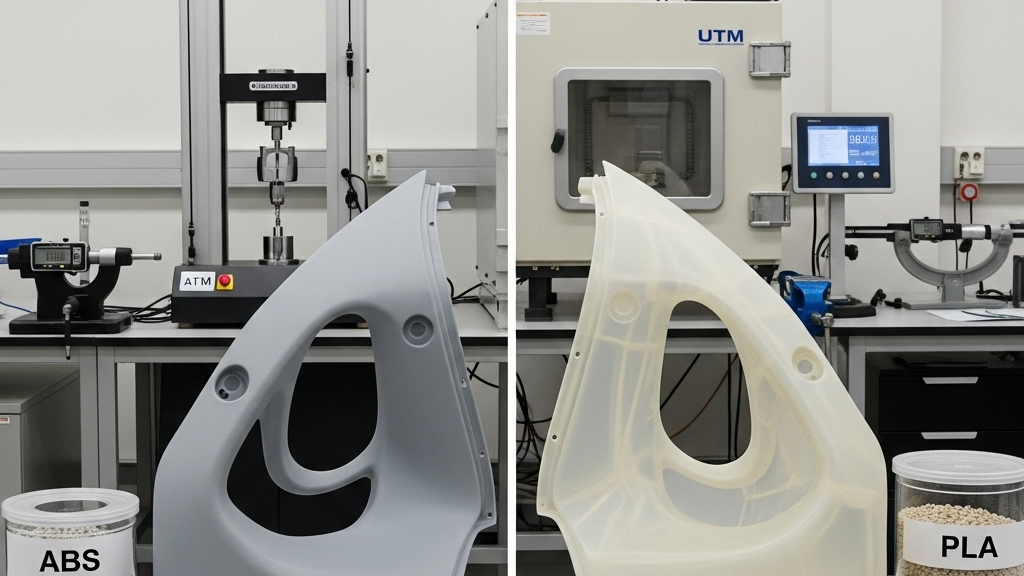

Real-world application cases can more intuitively reveal the stability differences and challenges of ABS and PLA in large injection molded parts. By analyzing the problems exposed by the two materials in different industries and application scenarios, we can gain a deeper understanding of their performance limitations and corresponding solutions. Discussing these real-world cases helps us better assess the reliability of the two materials under complex operating conditions.

- ABS Problems and Solutions: Large ABS parts are prone to deformation and internal stress due to uneven cooling, which can be alleviated by optimizing mold design and process control.

- PLA Problems and Solutions: Large PLA parts are prone to creep and softening at high temperatures or under long-term loads, which can be improved through modification, process optimization, or post-processing.

- Environmental Factors: PLA is susceptible to degradation due to moisture, and ABS is susceptible to aging due to ultraviolet light, requiring protective measures respectively.

- Dimensional Accuracy Maintenance: Material shrinkage may lead to dimensional deviations, requiring precise mold design and process control to improve accuracy.

Stability comparison

| Property | ABS(Acrylonitrile Butadiene Styrene) | PLA(Polylactic Acid) | Stability Impact Assessment |

|---|---|---|---|

| Creep Resistance | Good | Poor, prone to creep | ABS is more stable under long-term load |

| Dimensional Stability | Good, less susceptible to environment | Poor, susceptible to temp/humidity | ABS maintains dimensions more stably long-term |

| Impact Strength | High | Low, brittle | ABS is more resistant to unexpected impacts |

| Temperature Resistance | High | Low, prone to softening | ABS is more stable at higher temperatures |

Overall Material Stability

Different types and applications of large components have different focuses on the material's mechanical strength, dimensional stability, environmental adaptability, and long-term reliability. In-depth analysis of these factors, combined with specific application scenarios, is necessary to determine which material can provide more reliable overall stability.

1.High-Precision Load-Bearing Components: For components that require high dimensional accuracy and load-bearing capacity over the long term, ABS typically provides more reliable stability.

2.High-Impact Toughness Components: For applications requiring high-impact toughness, ABS can better resist cracking, ensuring long-term structural integrity.

3.Harsh Environment Applications: In high-temperature or humid environments, ABS is typically more stable due to its better temperature and moisture resistance.

4.Trade-offs and Applications: ABS often provides more reliable overall stability in a wider range of applications due to its balanced performance, but the final choice should be made based on the specific application scenario.

Conclusion

PLA is more prone to stability issues in high-temperature, high-humidity, or long-term load-bearing situations. Therefore, for large injection molded parts where long-term overall stability is desired, especially when used in complex environments, ABS is often the more reliable choice. Comprehensive assessment of performance requirements and long-term reliability is necessary. Although high-performance PLA is also under development, ABS currently typically provides more reliable overall stability in a wider range of applications.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!