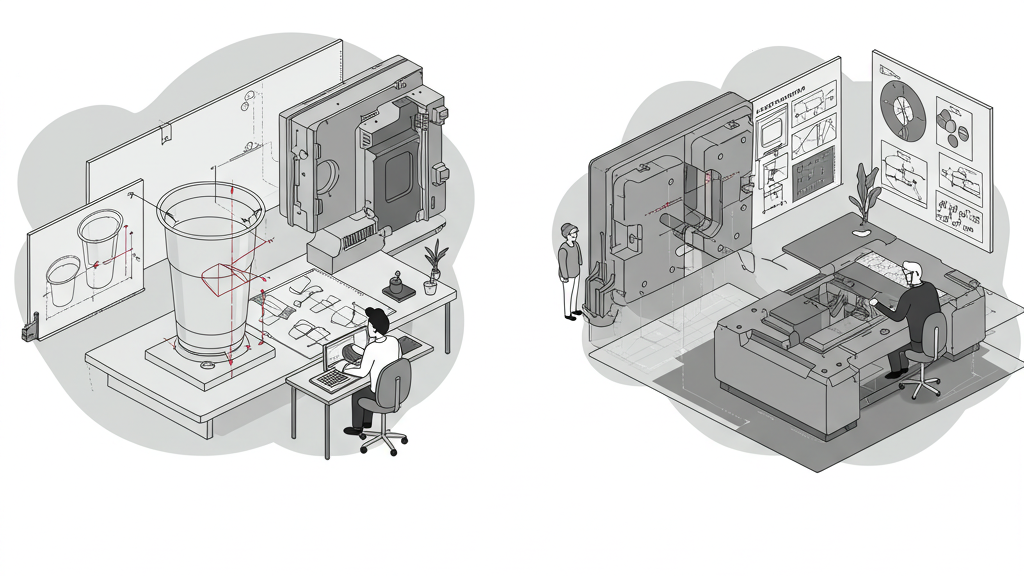

Injection molding is a critical process for manufacturing polypropylene products, and successful demolding directly affects product quality and production efficiency. Draft angle, as a core element of mold design, determines whether the product can be removed without damage. This article will explore the importance, influencing factors, and practical considerations of draft angle design for injection-molded polypropylene products from a professional perspective, providing a reference for engineers.

Draft angle is important in the molding of polypropylene products. However, a reasonable draft angle needs to comprehensively consider the material properties of polypropylene, the product structure, and mold constraints. We will analyze influencing factors such as material shrinkage, product geometry, surface texture, and process parameters to guide the selection and optimization of draft angles in practical applications.

Why is Draft Angle Needed for Polypropylene Injection Molding?

During the injection molding process, the polypropylene material tightly wraps around the mold core or cavity as it cools and shrinks, creating significant frictional resistance. Therefore, to ensure the product can be smoothly and safely removed from the mold, it is essential to carefully consider and set a reasonable draft angle during the design phase.

- Overcoming Shrinkage Resistance: Pre-setting a draft angle effectively overcomes the demolding resistance caused by the cooling shrinkage of polypropylene.

- Avoiding Mechanical Interlocking: A reasonable draft angle helps eliminate mechanical interlocking caused by mold defects or unevenness, enabling smooth demolding.

- Protecting Product Quality: Designing an appropriate draft angle significantly reduces the force required for demolding, preventing product damage.

- Improving Production Efficiency: Scientific draft angle design can reduce demolding resistance, accelerate demolding speed, and thereby improve production efficiency.

What Factors Influence Polypropylene Draft Angle?

Determining the required draft angle for injection-molded polypropylene products is a complex process involving many factors. The material properties of polypropylene itself, such as shrinkage rate and elastic modulus, as well as the product's geometry and surface treatment, will directly affect the size of the required draft angle.

- Material Shrinkage: Higher polypropylene shrinkage rates typically require larger draft angles.

- Product Geometry: Complex polypropylene product structures often require larger draft angles.

- Surface Texture: Rough textures on the product surface increase demolding resistance and require larger draft angles.

- Process Parameters: Improper injection molding process parameters may result in the need for larger draft angles.

How to Design Draft Angles for Different Shapes/Surfaces?

The diversity of polypropylene products dictates that draft angle design is not one-size-fits-all. For products with simple structures and smooth surfaces, relatively small draft angles can be used, while for products with complex curved surfaces, deep cavities, or special textures, a more cautious and detailed draft design strategy must be adopted.

- Simple Shallow Cavities: Shallow cavity products with uniform wall thickness and simple structures can use smaller draft angles.

- Complex Structures: Products with complex structures such as deep cavities, narrow slots, or reinforcing ribs require larger draft angles.

- Smooth Surfaces: Products requiring smooth surfaces should use the smallest possible and uniform draft angles.

- Textured Surfaces: Products with textured or grained surfaces must use significantly increased draft angles.

Main factors and design suggestions

| Key Influencing Factors | Specific Description | Design Recommendations | Recommended Draft Angle Range (Reference) |

|---|---|---|---|

| Polypropylene Shrinkage Rate | Degree of volume contraction of the material during cooling; higher shrinkage leads to tighter adhesion to the mold. | For PP materials with higher shrinkage rates, appropriately increase the draft angle. | 0.5° - 3°+ |

| Product Geometric Shape | Complexity of the product structure, such as deep cavities, narrow ribs, reinforcing ribs, protrusions, etc. | The more complex the structure, the larger the draft angle should be to avoid sticking or deformation. Deep cavities and narrow ribs require particular attention. | 1° - 5°+ |

| Product Surface Texture | Presence of texture, grain, or roughness on the surface. | The rougher the surface texture, the larger the required draft angle to ensure smooth demolding and protect the texture. | 3° - 7°+ |

| Injection Molding Parameters | Injection pressure, melt temperature, holding pressure time, cooling rate, etc. | Optimizing process parameters can reduce the adhesion force between the product and the mold, but draft angle design should consider the worst-case scenario. | Depends on specific circumstances |

Inspecting and Optimizing Polypropylene Draft Angles

Theoretical draft angle design is the foundation for ensuring smooth demolding of polypropylene products, but its ultimate rationality and effectiveness must be verified in actual injection molding production. Through careful observation and scientific analysis, we can assess whether the current draft design can meet production needs, avoiding problems such as poor demolding, product deformation, or damage.

1.Observe the Demolding Process: Judge whether the draft angle is appropriate by observing the smoothness of demolding and the required force.

2.Inspect Product Surface Quality: Scratches, abrasions, or deformation on the product surface may indicate insufficient draft angle.

3.Conduct Dimensional Accuracy Measurements: Large deviations between product dimensions and design may be related to deformation during the demolding process, requiring optimization of the draft angle.

4.Perform Mold Maintenance and Inspection: Regularly maintain the mold to eliminate mold factor interference and more accurately assess the effectiveness of the draft angle.

Conclusion

Draft angle design for injection-molded polypropylene products is crucial, directly affecting demolding smoothness and product quality. The design needs to comprehensively consider factors such as polypropylene properties, product shape, and surface requirements. A reasonable goal is to ensure smooth demolding while minimizing the draft angle as much as possible to improve production efficiency and product precision.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!