ABS injection molding is widely used, but the melt flow directly determines the filling effect and product quality. Precise control of melt flow is key to obtaining high-quality products. This article will explore how to effectively control the flow of ABS melt from materials, processes, and mold design to ensure perfect filling of the cavity.

Evidently, the melt flow of ABS is crucial for filling. So, what are the core factors influencing its flow behavior? And how should we finely control these factors to ensure smooth melt injection into the mold? Next, we will focus on analyzing the key elements that affect the melt flow of ABS and explore how to achieve effective control through process optimization, mold adjustment, and material selection.

What are the main influencing factors of ABS melt flow?

The flowability of ABS injection molding melt is a complex behavior influenced by a variety of factors. Understanding these key influencing factors is the primary prerequisite for effectively controlling melt flow and ensuring complete filling of the cavity.

- Temperature: Increasing the melt and mold temperature can effectively reduce the viscosity of the ABS melt and enhance its flowability.

- Pressure: Appropriately increasing the injection and holding pressure can drive and maintain the flow of ABS melt within the mold cavity.

- Shear Rate: A higher injection speed can increase the shear rate of the ABS melt, reduce viscosity, and improve flowability.

- Material Properties: Selecting ABS materials with a high melt flow index or adjusting the components can directly affect the flow capability of the melt.

How to optimize melt flow through process parameter optimization?

After understanding the key factors influencing ABS melt flowability, the next step is to explore how to achieve optimized control of melt flowability in actual injection molding production through fine-tuning process parameters. Reasonable process parameter settings can significantly improve the filling capacity of the melt, reduce defects, and ultimately obtain high-quality injection molded parts.

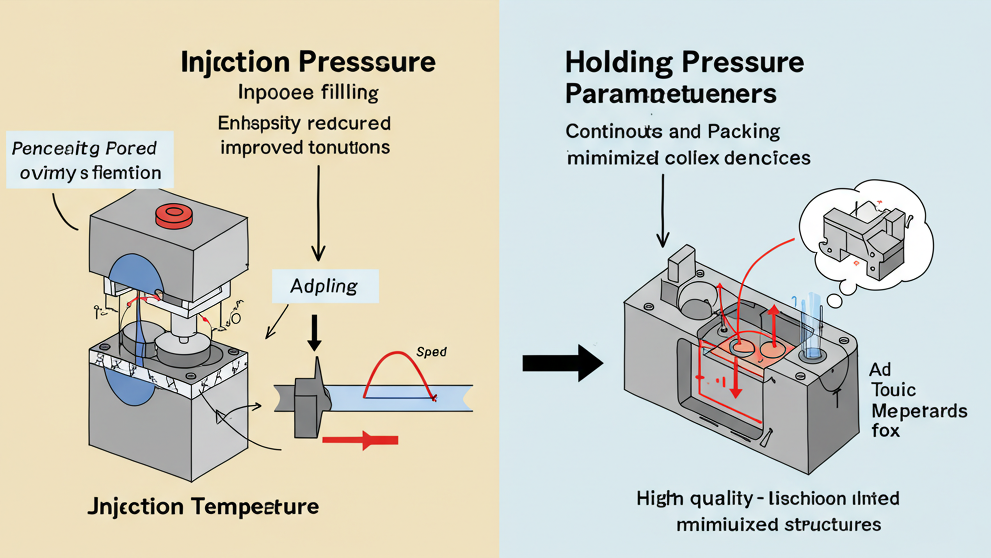

- Injection Temperature: Appropriately increasing the injection temperature can significantly reduce the viscosity of the ABS melt and improve filling.

- Injection Pressure and Speed: Increasing the injection pressure and optimizing the injection speed profile can enhance the driving force of the melt and improve flowability.

- Holding Pressure Parameters: Reasonably setting the holding pressure and time ensures continuous filling and packing of the melt.

- Mold Temperature: Appropriately increasing the mold temperature extends the melt flow time, which is conducive to filling complex structures.

How does mold design control melt flow?

As the key carrier for plastic molding, the design details of the mold have a direct and profound impact on the flow behavior of ABS melt. Through ingenious structural optimization, the flow direction of the melt can be effectively guided and controlled, reducing flow resistance, and ensuring that the melt can be evenly distributed to every corner of the mold cavity, thereby achieving the desired filling effect.

- Feed System: Optimizing the feed system design can reduce melt flow resistance and ensure smooth filling.

- Venting System: Properly setting the venting system can discharge gas in time, avoiding obstruction of melt flow.

- Runner Layout: Balancing the runner layout ensures that the melt arrives at each cavity or part synchronously, achieving uniform filling.

- Auxiliary Flow Structures: Using auxiliary structures such as flow guides can guide melt flow and improve filling efficiency.

Practical guide to melt fluidity control

| Control Aspect | Key Adjustment | Expected Outcome |

|---|---|---|

| Material | Select High MFI ABS | Improved Flow, Facilitates Filling |

| Temperature | Increase Melt & Mold Temp | Reduced Viscosity, Enhanced Flow |

| Pressure & Speed | Increase Injection P, Opt Speed | Increased Driving Force, Fast Fill |

| Holding Pressure | Proper Hold P & Time | Ensured Filling, Reduced Shrinkage |

| Gating System | Optimize Runner Design | Reduced Resistance, Smooth Fill |

| Venting | Implement Effective Vents | Avoided Air Traps, Complete Fill |

| Runner Balance | Balance Runner Layout | Uniform Fill, Reduced Weld Lines |

| Auxiliary Struct | Use Flow Aids, etc. | Guided Flow, Improved Local Fill |

The Impact of Material on Flowability and Filling

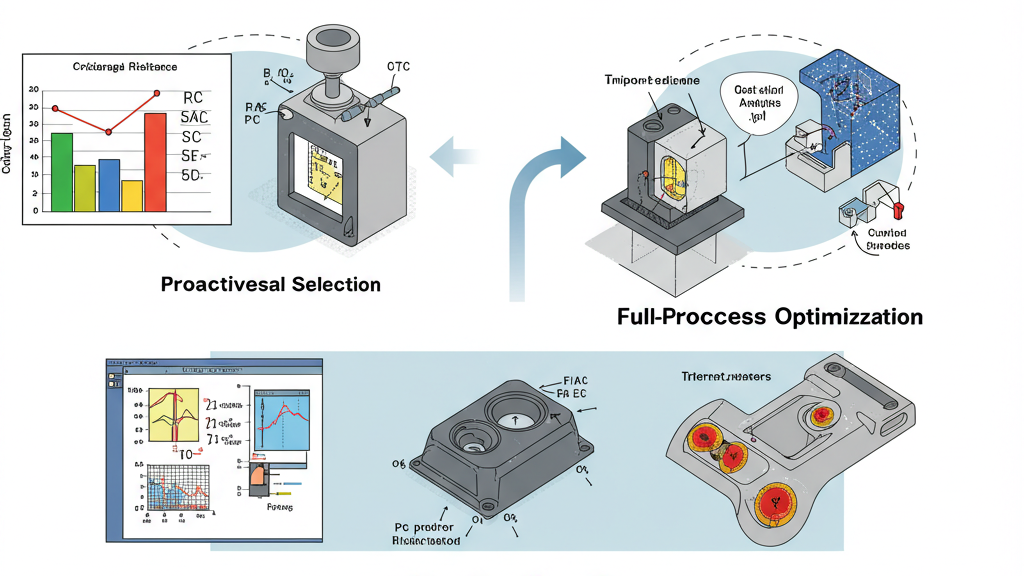

In addition to optimizing injection molding process parameters and mold design, selecting the appropriate ABS material itself is crucial for melt flowability and the final filling effect. For different grades of ABS resin, the inherent melt flow index directly determines the melt's flow capability under the same conditions. Choosing ABS materials with a higher melt flow index can improve melt flowability from the source and reduce filling difficulty. This often achieves twice the result with half the effort, especially when facing complex structures or thin-walled products.

1.Melt Flow Index: Selecting ABS materials with a high melt flow index can directly improve melt flowability and improve filling effect.

2.Molecular Weight Distribution: ABS with a narrow molecular weight distribution typically has more stable melt flowability, which is beneficial for filling control.

3.Fillers and Reinforcing Agents: Adding fillers and reinforcing agents may reduce the flowability of the ABS melt, requiring a trade-off to be considered.

4.Modification and Blending: The melt flow performance of ABS can be improved by blending with other polymers or adding additives.

Conclusion

Effectively controlling the flowability of ABS injection molding melt and ensuring filling requires comprehensive consideration of materials, processes, and molds. Understanding temperature, pressure, shear rate, and material properties is fundamental. Fine-tuning injection temperature, pressure and speed, holding pressure, and mold temperature is essential. Only by combining material selection, process optimization, and mold design can a synergistic effect be achieved, precisely controlling the flowability of ABS melt and obtaining high-quality products.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!