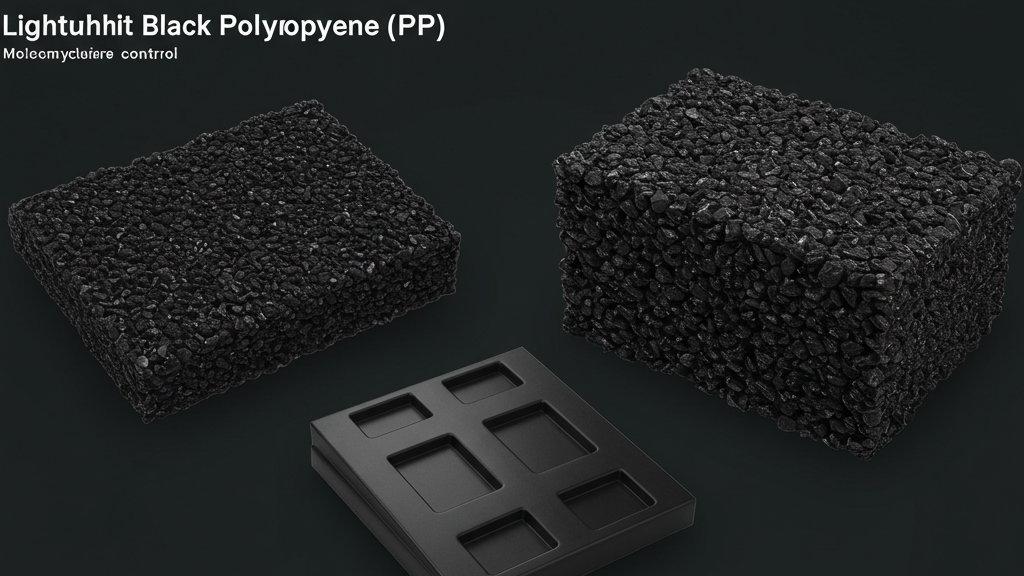

Lightweighting is a significant trend in current industrial development, and black PP material is no exception. How to achieve weight reduction while ensuring key strength performance is a common focus of materials science and the business sector. Companies that master the core technology of lightweight black PP will gain an advantage in market competition.

Achieving lightweighting of black PP is not simply about reducing density. The key lies in how to ensure or even improve material strength while reducing weight. We will focus on introducing several core technology strategies to explore how to strike a balance between "strength" and "lightweighting" through innovation in molecular structure, microscopic morphology, and macroscopic design.

What are the main technical challenges of lightweight black PP?

Currently, the primary technical bottleneck in the pursuit of lightweighting black polypropylene (PP) materials lies in how to maintain its key mechanical properties while reducing the material density. Overcoming this challenge requires a thorough understanding of the limitations of traditional lightweighting methods for black PP and actively exploring new material modification and structural optimization strategies.

- Density and Strength Balance: How to maintain the strength of black PP while reducing density is the primary challenge.

- Performance Impact of Black Pigments: The addition of pigments such as carbon black may negatively affect the mechanical properties and processability of black PP.

- Cost of Lightweighting Modification: Advanced lightweighting technologies are relatively expensive, requiring a balance between performance improvement and economics.

- Design and Process Compatibility: The application of lightweight materials also needs to address the compatibility of structural design and traditional molding processes.

What are the innovative strategies and technologies for lightweight black PP?

Faced with the technical bottlenecks in lightweighting black PP, materials scientists and engineers are actively exploring diverse innovative strategies and cutting-edge technologies. These methods encompass everything from microscopic optimization of material components to macroscopic product structure innovation, as well as fine-grained control of the production and manufacturing process, aiming to provide practical solutions for the realization of high-strength lightweight black PP.

- High-Performance Fillers and Foaming: Integrating high-strength fillers and foaming technology can achieve lightweighting and strength enhancement of black PP.

- Lightweight Structures and Integrated Molding: Innovative structural design and integrated molding help manufacture high specific strength lightweight black PP components.

- Precision Injection Molding and Micro-Molding: Precise control of molding processes enables the manufacture of thin-walled and high-strength black PP products.

- Intelligence and Sustainability: The combination of intelligent materials and recycling technology provides new ideas for lightweighting black PP.

What are the differences in requirements for lightweight black PP across different industries?

The demand for lightweight black PP is not uniform across different industries. The automotive and home appliance sectors, due to their product characteristics and application scenarios, have significant differences in the strength indicators and weight reduction goals for the material. These differences directly determine the direction of technology selection.

- Automotive Industry: The automotive industry has the most stringent requirements for strength and safety while pursuing extreme weight reduction in lightweight black PP.

- Home Appliance Industry: In the application of lightweight black PP, the home appliance industry focuses more on achieving cost-effectiveness while meeting basic performance needs.

- Packaging Industry: The packaging industry's demand for lightweight black PP lies in balancing lightness and protective function, and also paying attention to the environmental friendliness of the material.

- Electronics and Electrical Appliance Industry: The electronics and electrical appliance industry needs to balance thinness, structural strength, and specific functional integration requirements in the application of lightweight black PP.

Realization method of high strength and lightweight black PP

| Method | Key Technologies/Strategies | Strength Assurance Measures | Lightweighting Effect | Applicable Fields |

|---|---|---|---|---|

| High-Performance Fillers | Nanofillers, Long Glass Fiber Reinforcement | Enhances Matrix Strength and Stiffness | Significantly Reduces Material Density | Automotive Structural Parts, Electronics |

| Advanced Foaming | Supercritical Fluid, Physical/Chemical Synergistic Foaming | Controls Cell Structure, Maintains Impact Strength | Effectively Reduces Part Weight | Automotive Interior, Packaging |

| Lightweight Structure | Biomimetic Designs like Honeycomb, Rib Reinforcement | Optimizes Load-Bearing Capacity, Reduces Material Usage | Achieves Significant Weight Reduction | Automotive Components, Construction |

| Precision Injection Molding | Dynamic Mold Temperature, High-Pressure Injection Molding | Improves Part Density and Uniformity | Enables Thin-Wall Design | Precision Electronics, Thin-Wall Packaging |

The Commercial Value of High-Strength, Lightweight Black PP

Developing and applying high-strength, lightweight black PP materials will enable companies to build significant competitive advantages and expand vast market opportunities. Companies that are the first to master related technologies can meet the growing lightweighting demands of downstream industries with high-performance, low-weight products, thereby occupying a more favorable position in the supply chain and earning higher product added value.

1.Seize Market Opportunities: Companies that are the first to meet lightweighting demands will gain a market advantage.

2.Expand High-End Applications: High-performance materials help companies enter high value-added fields.

3.Establish an Eco-Friendly Image: Lightweight products enhance a company's brand competitiveness and attractiveness.

4.Build Technical Barriers: Unique technical advantages ensure a company's long-term market leadership.

Conclusion

Achieving lightweighting of black PP while ensuring strength is not only an inevitable trend to meet environmental protection and market demands, but also holds tremendous commercial value. Companies that successfully develop and apply high-strength, lightweight black PP materials will gain a first-mover advantage in a rapidly growing market, expand into high-end applications, establish an environmentally friendly image, and build hard-to-replicate technological barriers, ultimately achieving sustainable commercial success.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!