Acrylonitrile-Butadiene-Styrene (ABS) copolymer, as a commonly used engineering plastic, is favored for its mechanical and processing properties. In electrical applications, the electrical insulation of ABS is crucial. This article will focus on the electrical characteristics of ABS plastic sheets from a professional perspective, evaluate their potential as electrical insulating materials, and analyze the key factors affecting their insulation performance, providing a reference for material selection.

After understanding the basic properties of ABS, it is crucial to examine its electrical performance indicators in depth. Parameters such as volume resistivity, surface resistivity, and dielectric strength directly reflect the insulation capability of ABS. Next, we will specifically analyze the numerical ranges of these key parameters and, in combination with practical applications, evaluate the insulation performance of ABS plastic sheets in different electrical environments.

What are the main electrical properties of ABS?

As a common engineering plastic, the electrical properties of ABS plastic are crucial for its application in the electronic and electrical fields. Understanding its key electrical parameters and benchmarking them against industry standards is the primary step in evaluating whether ABS is suitable as an electrical insulation material.

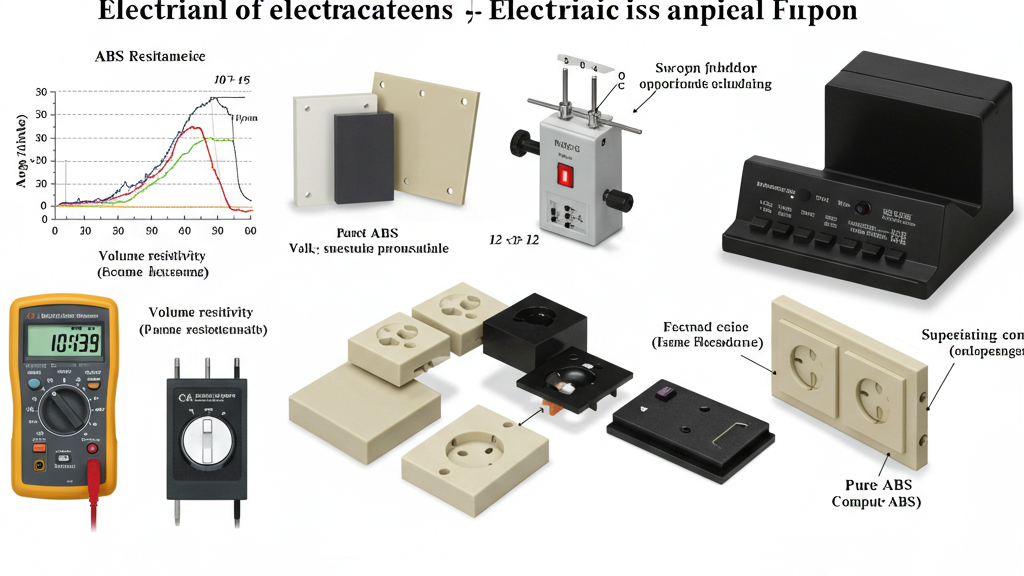

- Volume Resistivity: The volume resistivity of pure ABS is typically in the range of 10^14 ~ 10^16 Ω·cm, which may decrease with modified ABS.

- Dielectric Strength: The dielectric strength of ABS is generally 15 ~ 35 kV/mm.

- Industry Standards: The electrical performance of ABS is referenced against general plastic testing standards, but is not as strict as professional insulation materials.

- Application Assessment: ABS is suitable for some low-to-medium voltage insulation applications. Specific applications require evaluation and may necessitate the use of modified materials.

What factors influence the insulation properties of ABS?

The electrical insulation performance of ABS plastic sheets is not fixed and unchangeable; various external and internal factors can significantly affect it. A deep understanding of these influencing factors and their extent is crucial to ensuring the reliability of ABS in electrical applications.

- Environmental Humidity: Increased humidity significantly reduces the resistivity of ABS, impairing its insulation.

- Temperature: Increased temperature typically reduces the resistivity of ABS, with a sharp decline in insulation performance at high temperatures.

- Material Modification: Adding different substances can significantly alter the electrical insulation properties of ABS.

- Frequency and Voltage: High frequency and high voltage increase the dielectric loss of ABS, reducing its insulation capacity.

In which insulation scenarios is ABS commonly used?

Although ABS plastic is not a professional insulating material, its comprehensive properties make it visible in certain electrical applications. Understanding the specific applications and performance of ABS in these scenarios, as well as its inherent limitations, helps us to more reasonably assess its scope of application.

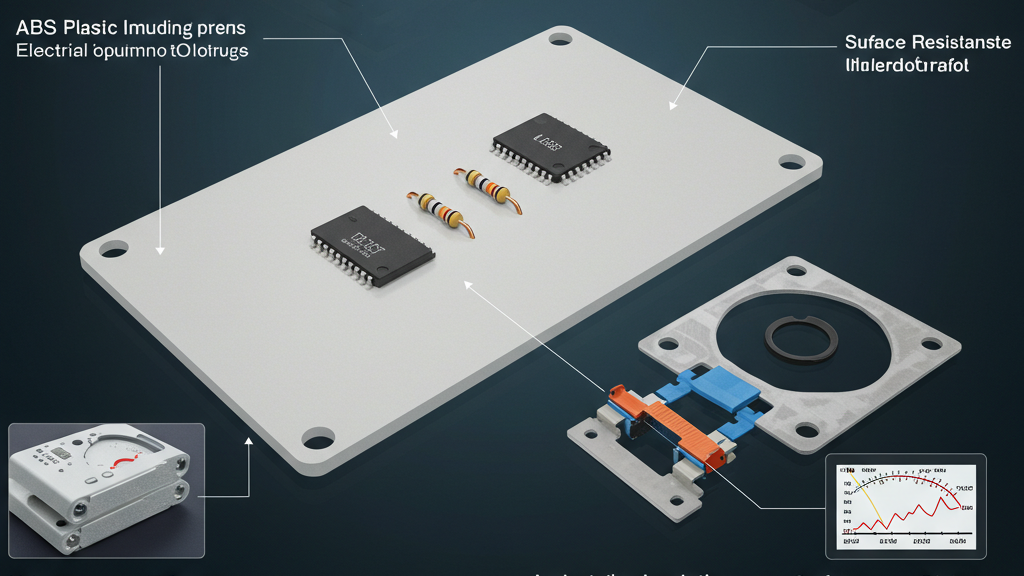

- Low-Voltage Electrical Appliance Housings and Structural Components: ABS is commonly used for low-voltage electrical appliance housings, but its use is limited in high-humidity, high-temperature, or arc-resistant scenarios.

- Non-Critical Insulation Parts in Electronic Devices: ABS can be used as non-critical insulation parts in electronic devices, but it is not suitable for components with high insulation requirements.

- Automotive Interior and Low-Voltage Electrical Components: ABS is used in low-voltage components in automotive interiors, but it is not suitable for high-temperature environments.

- Low-Voltage Insulation Components in Laboratory and Teaching Equipment: ABS can be used in low-voltage experimental teaching equipment, but it is not suitable for high-precision, high-voltage environments.

Application and performance consideration of ABS plastic sheet in electrical insulation field

| Application Scenario | ABS Performance | Key Performance Considerations | Limitations |

|---|---|---|---|

| Low-Voltage Electrical Enclosures | Basic Insulation, Easy to Mold | Insulation Strength, Moisture Resistance, Flame Retardancy | High Humidity/Temperature, Poor Arc Resistance |

| Non-Critical Electronic Components | Insulation Support and Fixing | Insulation Resistance, Heat Resistance | Not Suitable for High Insulation Requirements, Limited Heat Resistance |

| Automotive Interior Low-Voltage Components | Some Insulation Protection, Wear Resistant | Insulation Performance, Temperature Resistance | Not Suitable for High-Temperature Environments |

| Low-Voltage Lab Insulation Components | Easy to Process, Various Colors | Insulation Performance, Chemical Resistance | Not Suitable for High-Voltage or Strong Corrosive Environments |

ABS Insulation Compared to Other Materials

Compared to other common insulating materials, the electrical insulation performance of ABS plastic sheets is generally at a medium level. Its advantages are relatively low cost, ease of processing and molding, and certain mechanical strength and chemical corrosion resistance, making it competitive in some low-voltage electrical and electronic applications where insulation requirements are not high.

1.Electrical Insulation Performance: The insulation capacity of ABS is generally inferior to engineering plastics such as polycarbonate and polyamide and is comparable to polyvinyl chloride but with some differences.

2.Main Advantages: Relatively low cost, easy processing and molding, and certain comprehensive mechanical and chemical properties.

3.Main Disadvantages: Relatively poor high-temperature resistance, arc resistance, and susceptibility to humidity, leading to a decrease in insulation performance.

4.Trade-offs for Applicable Scenarios: Suitable for low-voltage electrical applications where insulation requirements are not high but cost and processability are important.

Conclusion

ABS plastic sheets, as a common engineering plastic, offer a moderate level of electrical insulation performance. When selecting ABS as an electrical insulation material, it is essential to fully assess the specific application environment and electrical performance requirements, weigh its cost and processing advantages against its inherent insulation limitations, and, when necessary, consider using specialized insulating materials with superior performance to ensure the safety and reliability of the electrical system.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!