Polymer molding is a crucial aspect of manufacturing, with injection molding and plastic injection molding often used interchangeably. Do these two terms refer to the same process? This article will analyze their essential characteristics and industry perception from a professional perspective, aiming to provide an authoritative answer regarding the relationship between the two.

The basic principle and key steps of injection molding lie in the precise injection of molten plastic and cooling for shaping. However, what does the term "plastic injection molding" represent? Does it emphasize specific aspects or application areas of injection molding? We will explore the connotation of "plastic injection molding" and its connections and differences with "injection molding" to gain a more comprehensive understanding of practical applications within the industry.

What's the difference in the technology of molten plastic injection?

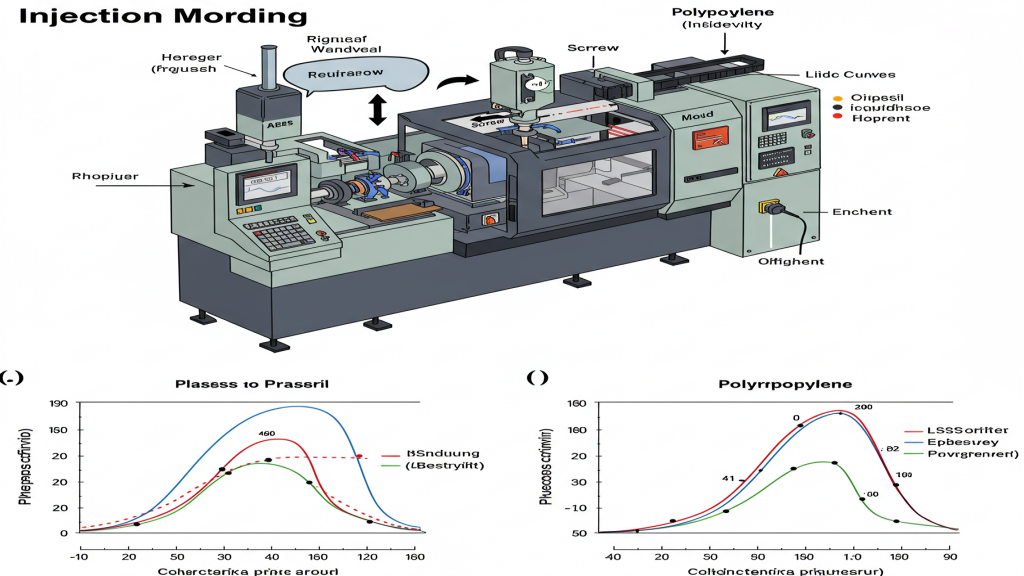

The widespread application of plastic products relies on efficient molding processes, among which injection molding and plastic injection molding are two common terms. This article will focus on the subtle differences between these two processes in the core– molten plastic injection technology, exploring whether there are fundamental differences in terms of injection unit design, control logic, and melt transport mechanisms.

- Injection Unit Design: The two terms may imply differences in the structural design of the injection unit in history or in special applications, such as screw type versus plunger type.

- Injection Pressure and Speed Control: For different needs, there may be subtle differences in the control strategies and fine adjustments of injection pressure and speed.

- Melt Transport and Nozzle Design: Theoretically, the nozzle type and melt runner design may have specific technical preferences due to the different terminologies of the process.

- Back Pressure Control and Metering Accuracy: The two terms of the process may have subtle technical differences in the implementation of back pressure control and the accurate control of the injection volume.

What are the differences in process control for different plastics?

In current industrial practice and technical literature, "injection molding" and "plastic injection molding" are, in most cases, interchangeable. Both refer to the molding method of injecting molten plastic into a mold under high pressure and cooling it to solidify. The descriptions of technical parameters, equipment principles, and process flow are usually the same, and there is no ambiguity caused by using different terms.

- Melt Temperature Control: For different thermal properties of plastics, the two processes may differ in heating control precision and strategies.

- Injection and Holding Pressure Control: To adapt to the different fluidity of plastics, the optimization and control of the pressure curve may vary.

- Cooling Rate and Mold Temperature Control: For different crystallization characteristics of plastics, cooling and mold temperature control methods may differ.

- Special Plastic Process Adjustment: For special plastics such as glass fiber reinforced plastics, the two processes may have specific parameter adjustment recommendations.

What are the key differences in mold design and process parameters?

The coexistence of these two terms is likely due to linguistic habits and translation differences. "Injection" directly describes the action of injecting molten material into a mold; while "Injection Molding" emphasizes the "molding" of "plastic" through the injection method. In different contexts or industry practices, one may be preferred over the other, but this does not mean that there is a fundamental technical difference between the two.

- Gating System Design Philosophy: The two process terms may correspond to different gating system design preferences or industry standards.

- Cooling System Optimization Strategies: For different processes, the layout and optimization strategies of the mold cooling system may differ.

- Venting System Design Considerations: The two processes may have different emphases on mold venting groove design and the application of auxiliary venting technologies.

- Process Parameters and Mold Collaboration: For specific mold characteristics, the two processes may adopt different parameter optimization methods or recommended ranges.

Comparative analysis of technological elements

| Technical Element | Injection Molding (Possible Emphasis) | Plastic Injection Molding (Possible Emphasis) | Potential Difference Description |

|---|---|---|---|

| Melt Injection | Injection Unit Structure Emphasis | Injection Process Control Emphasis | Subtle differences in injection equipment and control |

| Process Parameter Control | Temperature Control Strategy Emphasis | Pressure-Speed Control Emphasis | Different emphasis on parameter adjustments for plastics |

| Mold Design | Gate System Design Emphasis | Cooling System Design Emphasis | Potential preferences in mold structure and runner design |

| Automation & Intelligence | Automation Application Emphasis | Intelligence Application Emphasis | Different focus in automation and intelligent monitoring |

Potential Technical or Design Differences from the Perspective of Equipment and Molds

"Although 'injection molding' and 'plastic injection molding' are often used interchangeably in practice, if we examine them from the perspective of the two core elements of plastic molding—equipment and molds—we may find some subtle differences in potential technology or design.

1.Injection Unit Drive and Precision: Injection molding and plastic injection molding equipment may have differences in the driving method and precision control of the injection unit in historical or specific application areas.

2.Plasticizing Unit Design and Efficiency: The two process terms may correspond to subtle differences in the design of the plasticizing screw, affecting plasticizing efficiency and melt quality.

3.Mold Material and Surface Treatment: For different processes, there may be habitual or industry preferences in the selection of mold materials and surface treatment.

4.Mold Structure Standardization and Customization: There may be differences in the degree of standardization and customization of mold structures between injection molding and plastic injection molding."

Conclusion

In summary, "injection molding" and "plastic injection molding" generally refer to the same plastic processing technology in modern industry. The core principle is to inject molten plastic into a mold and cool it to form a solid part. Therefore, considering them as the same process is the more common and accurate understanding currently.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!