Achieving a flawless surface finish in injection-molded parts is like crafting a fine piece of furniture—it takes precision, attention to detail, and the right tools. Whether it’s for aesthetics or functionality, the surface quality of your parts can greatly impact their performance and appeal.

To improve the surface finish of injection-molded parts, you need to focus on material selection, mold design, processing parameters, and post-molding techniques. Each of these factors plays a key role in minimizing defects and achieving a smooth, polished finish.

Let’s explore each of these strategies and how they contribute to enhancing surface quality.

Why does material selection impact surface finish?

Think of material selection as choosing the perfect paint for your wall—without the right base, even the best technique won’t yield great results.

The material used in injection molding significantly affects the surface finish. Certain plastics, like ABS, PMMA, and polycarbonate, naturally have better flow properties and produce smoother finishes. Additives such as lubricants, fillers, or pigments can further enhance the appearance and reduce surface imperfections.

Examples of materials and their surface finish quality:

| Material | Surface Finish | Best Application |

|---|---|---|

| ABS | High gloss, smooth | Consumer electronics, automotive trim |

| PMMA (Acrylic) | Transparent, scratch-resistant | Optical lenses, displays |

| Polycarbonate | Impact-resistant, clear | Protective covers, medical devices |

By selecting a resin optimized for your application, you can reduce flow lines, weld lines, and other defects that impact surface quality.

How does mold design improve surface finish?

Mold design is like creating the blueprint for a building—if it’s poorly planned, the end result will show flaws.

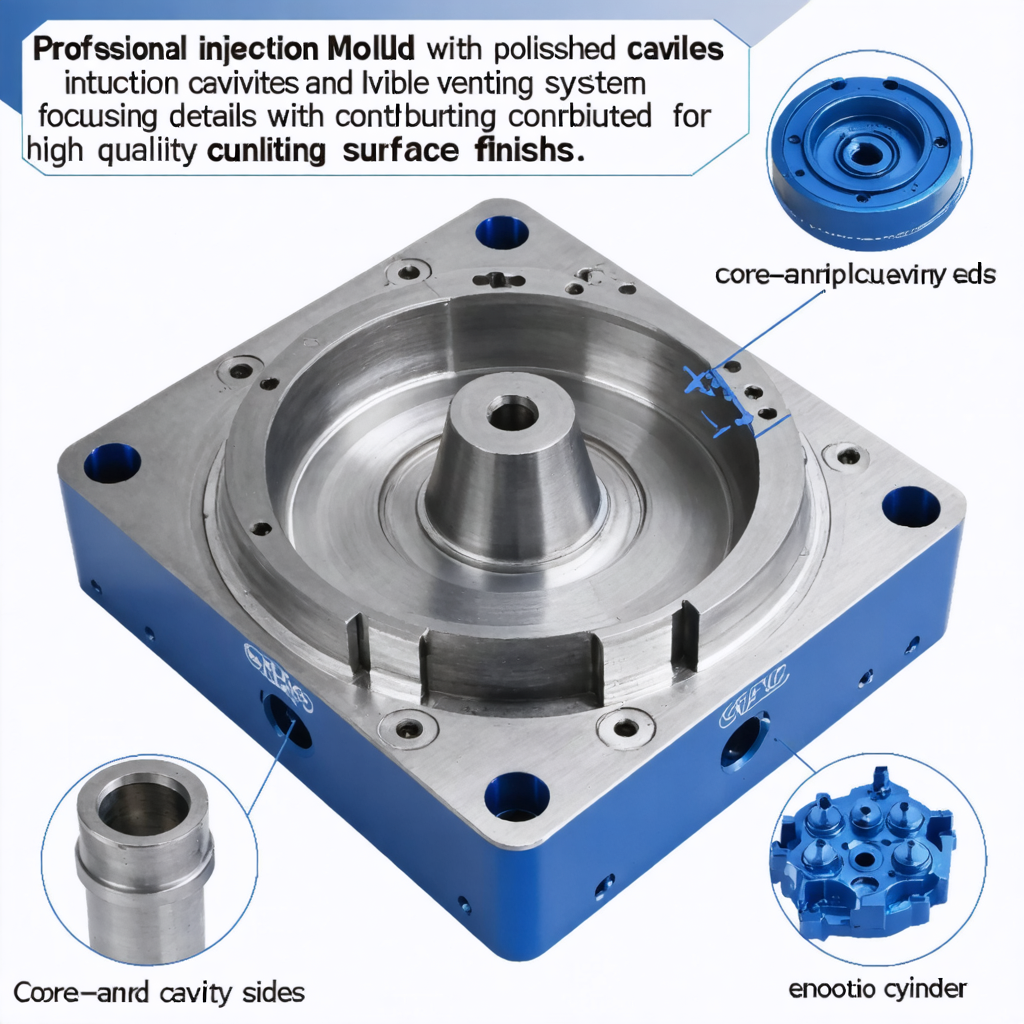

Key mold design features that improve surface finish:

- Polished Mold Cavities: Polishing the mold cavity surface transfers directly to the part, ensuring smoothness.

- Venting: Adding vents prevents trapped air, which can create rough patches or voids.

- Gate Placement: Proper gate location minimizes weld lines and flow marks.

By optimizing the mold design, you ensure uniform material flow, which reduces surface defects and enhances the overall finish.

What processing parameters affect surface finish?

Processing parameters are like the dials on a machine—tuning them correctly can make all the difference.

Key parameters to adjust for better surface quality:

- Injection Speed: Faster speeds help eliminate flow lines but must be balanced to avoid defects.

- Mold Temperature: A higher mold temperature ensures the material flows smoothly and produces a polished finish.

- Packing Pressure: Proper packing pressure ensures that the cavity is fully filled, reducing sink marks and voids.

| Parameter | Effect on Surface Finish | Suggested Adjustment |

|---|---|---|

| Injection Speed | Reduces flow lines | Adjust based on material |

| Mold Temperature | Enhances material flow and gloss | Increase slightly |

| Packing Pressure | Eliminates voids and sink marks | Optimize for part geometry |

Fine-tuning these parameters allows you to minimize common surface defects and achieve a superior finish.

What post-molding techniques can enhance surface finish?

If achieving perfection in molding is like building a solid foundation, post-molding techniques are the final polish that brings everything together.

Post-molding techniques to improve surface finish:

- Polishing and Buffing: Smooths out minor imperfections and enhances gloss.

- Coating or Painting: Adds color or texture while covering up surface irregularities.

- Texturing: Applies a deliberate pattern to the part, masking defects and adding aesthetic value.

These methods are especially useful for parts where the initial molding process can’t achieve the desired level of surface quality.

Conclusion

To improve the surface finish of injection-molded parts, focus on material selection, mold design, processing parameters, and post-molding techniques. By addressing these factors, you can achieve parts that are visually appealing, functionally superior, and free from defects.

For more insights on achieving high-quality injection-molded parts, visit our resource center or contact us. Let’s work together to create flawless surfaces for your next project!