Introduction

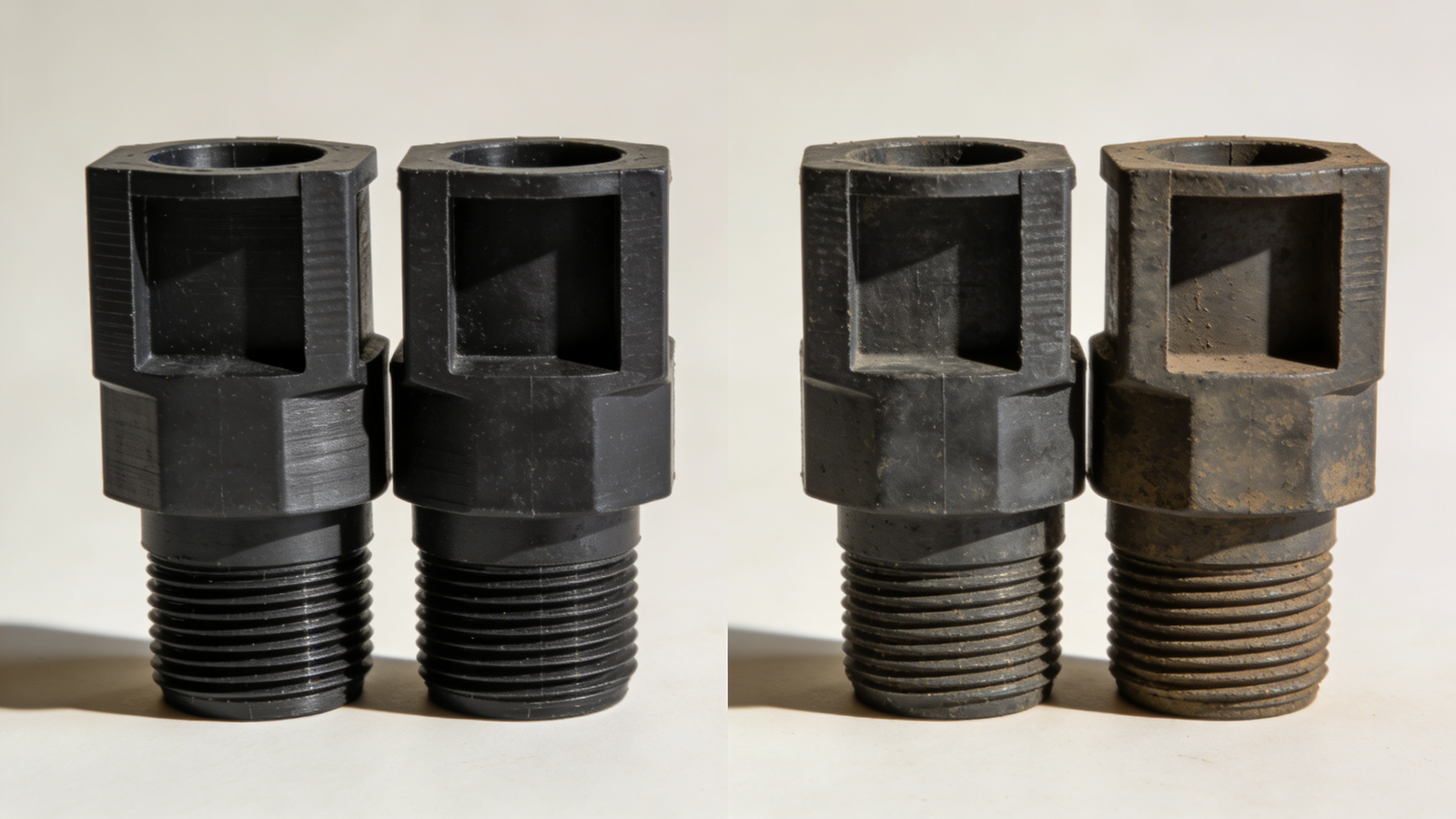

Chemical processing equipment operates long-term under harsh conditions such as strong acids, strong alkalis, elevated temperatures, and continuous media erosion. Traditional metal anti-corrosion solutions are increasingly limited by service life, maintenance cost, and design flexibility. PPS chemical-resistant injection molded parts, thanks to their highly stable molecular structure and outstanding chemical inertness, are becoming a key alternative for corrosion-resistant components.For chemical manufacturers pursuing long-term stable operation, the chemical resistance boundary of the material directly determines equipment safety margins and total cost of ownership.

In real purchasing decisions, buyers are more concerned about whether PPS injection molded parts truly fit specific chemical equipment components rather than material data alone. From the perspective of injection molded part manufacturing, Xiamen Ruicheng helps customers transform “material properties” into “deployable corrosion-resistant solutions.”

Which Core Corrosion-Resistant Components in Chemical Equipment Are Suitable for PPS Injection Molded Parts?

PPS chemical-resistant injection molded parts mainly serve structural support, media isolation, and long-term corrosion protection functions in chemical equipment. Their applications are not generic but focused on components exposed to high corrosion, complex geometries, and strict dimensional stability requirements. In pumps, valves, and reaction systems, PPS injection molded parts balance chemical resistance with molding consistency and reliability. Through optimized injection molding processes, Xiamen Ruicheng integrates PPS material performance with chemical equipment corrosion protection design, helping customers reduce overall corrosion-control complexity and improve system reliability.

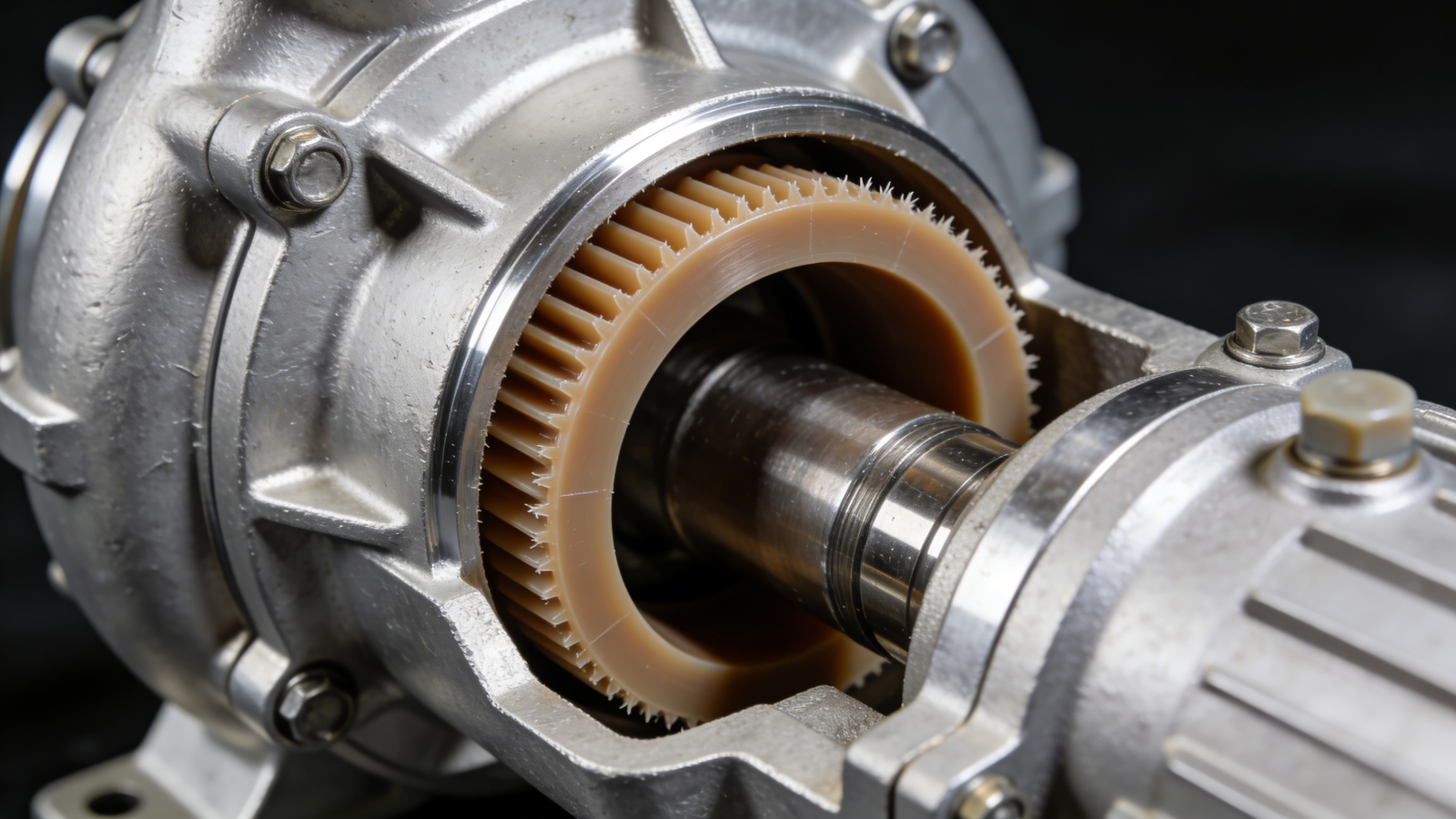

Pump liners: PPS injection liners isolate corrosive media inside chemical pumps while maintaining long-term dimensional stability.

Valve seats and valve core components: PPS valve seats withstand repeated opening and closing cycles while resisting chemical attack on sealing surfaces.

Auxiliary reactor components: PPS is ideal for non-pressure-bearing but highly corrosive zones requiring positioning or support structures.

Pipeline connectors: Injection molding enables complex flow channel designs, reducing corrosion risks at metal joints.

🔧 The true value of PPS injection molded parts lies in making corrosion resistance a structural capability, not an added protection layer.

How Do PPS Injection Molded Parts Ensure Long-Term Stability in Complex Chemical Media Environments?

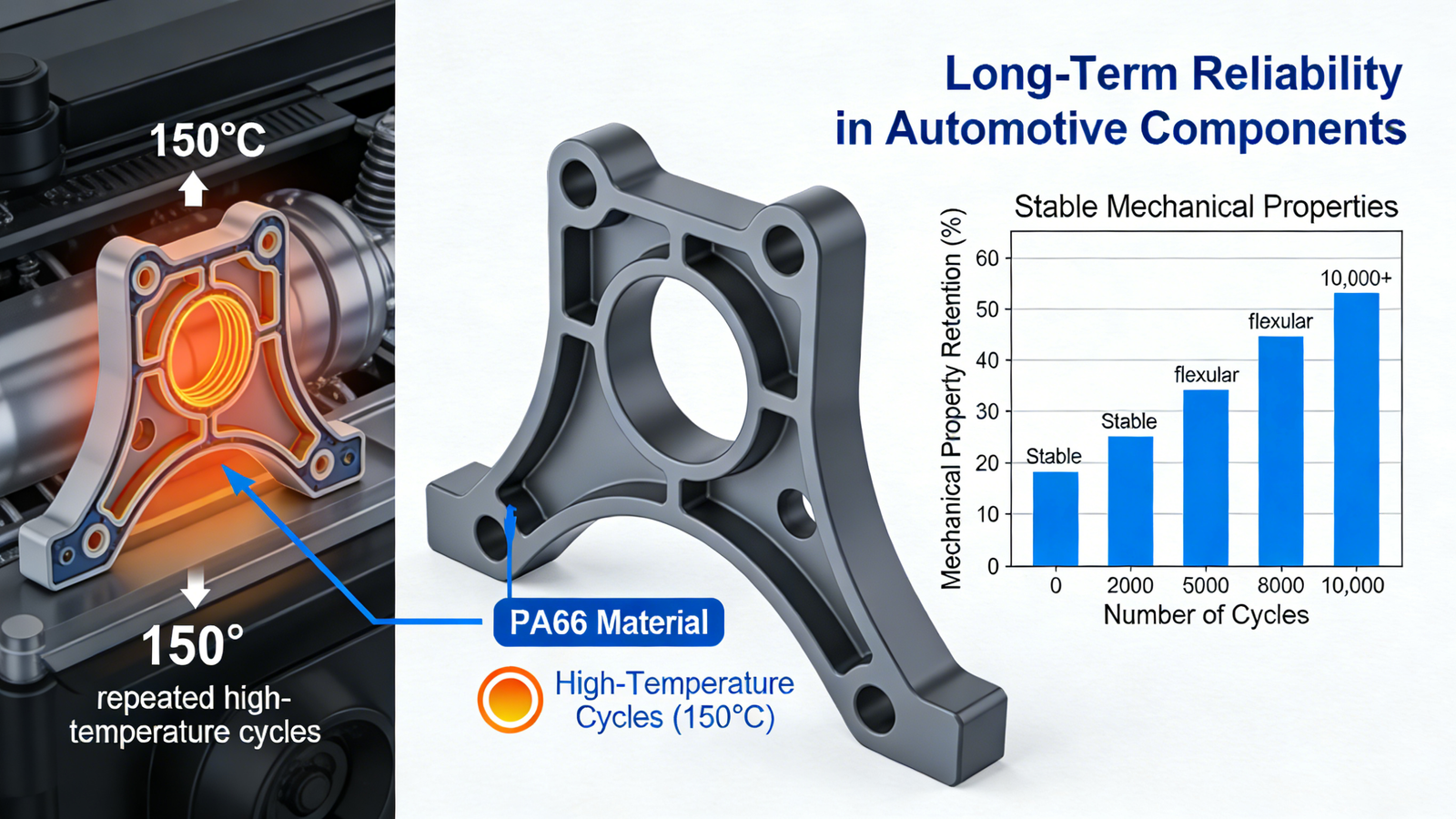

In chemical environments with multiple interacting media, single corrosion-resistance parameters are insufficient to guarantee long-term service. Real challenges arise from temperature fluctuations, media switching, and combined mechanical stresses. PPS chemical-resistant injection molded parts maintain consistent performance over time due to molecular stability and low moisture absorption. By combining PPS chemical resistance data with chemical compatibility analysis, Xiamen Ruicheng ensures every application scenario is supported by verifiable stability.

Resistance to media degradation: PPS exhibits minimal structural change under strong acids and alkalis, allowing predictable long-term performance.

Thermal-chemical synergy: PPS maintains mechanical and chemical balance even under high-temperature reaction conditions.

Long-term dimensional control: Low creep properties prevent deformation throughout the equipment lifecycle.

Process consistency: Stable injection molding windows reduce batch-to-batch variation during mass production.

🧪 Stability is not about stacking parameters—it is about long-term alignment between material and operating conditions.

How Can Buyers Determine Whether PPS Corrosion-Resistant Injection Parts Truly Fit Their Equipment?

Many chemical companies focus solely on whether PPS is corrosion-resistant, overlooking the importance of structural, processing, and application synergy. Truly compatible PPS corrosion-resistant injection molded parts must be designed by reverse-engineering actual equipment operating conditions. Xiamen Ruicheng integrates chemical equipment operating condition analysis with injection molded part design principles to help buyers eliminate mismatch risks during the procurement stage.

Condition-driven design: Component geometry is defined based on media type, temperature, and service cycles.

System-level evaluation: Parts are assessed within the equipment system rather than as isolated components.

Manufacturability verification: Injection molding feasibility is validated early in the design phase.

Lifecycle maintenance perspective: Replacement frequency and maintenance cost are evaluated beyond initial purchase price.

📌 Choosing the right PPS injection molded part is essentially a lifecycle-level decision.

Comparative Selection Reference for PPS Chemical-Resistant Injection Molded Parts in Corrosion Applications

| Comparison Dimension | PPS Injection Parts | PTFE Components | PVDF Injection Parts | Metal Corrosion-Resistant Parts |

|---|---|---|---|---|

| Chemical resistance stability | High | Very high | High | Medium |

| Design freedom | High | Low | Medium | Low |

| Dimensional stability | High | Low | Medium | High |

| Overall maintenance cost | Low | High | Medium | High |

For application-specific selection guidance tailored to your operating conditions, feel free to contact contact us

From Material Selection to Mass Production: PPS Corrosion-Resistant Injection Solutions

The real value of PPS chemical-resistant injection molded parts lies not only in material properties but in full-process control from design validation to mass production. Centered on injection molding manufacturing, Xiamen Ruicheng helps customers convert corrosion-resistance requirements into implementable engineering solutions. Through early-stage evaluation, mold development, and process control, customers achieve stable and repeatable supply of corrosion-resistant components.

1.Requirement analysis: Define constraints based on equipment conditions and chemical media.

2.Structural optimization: Balance corrosion resistance with injection molding feasibility.

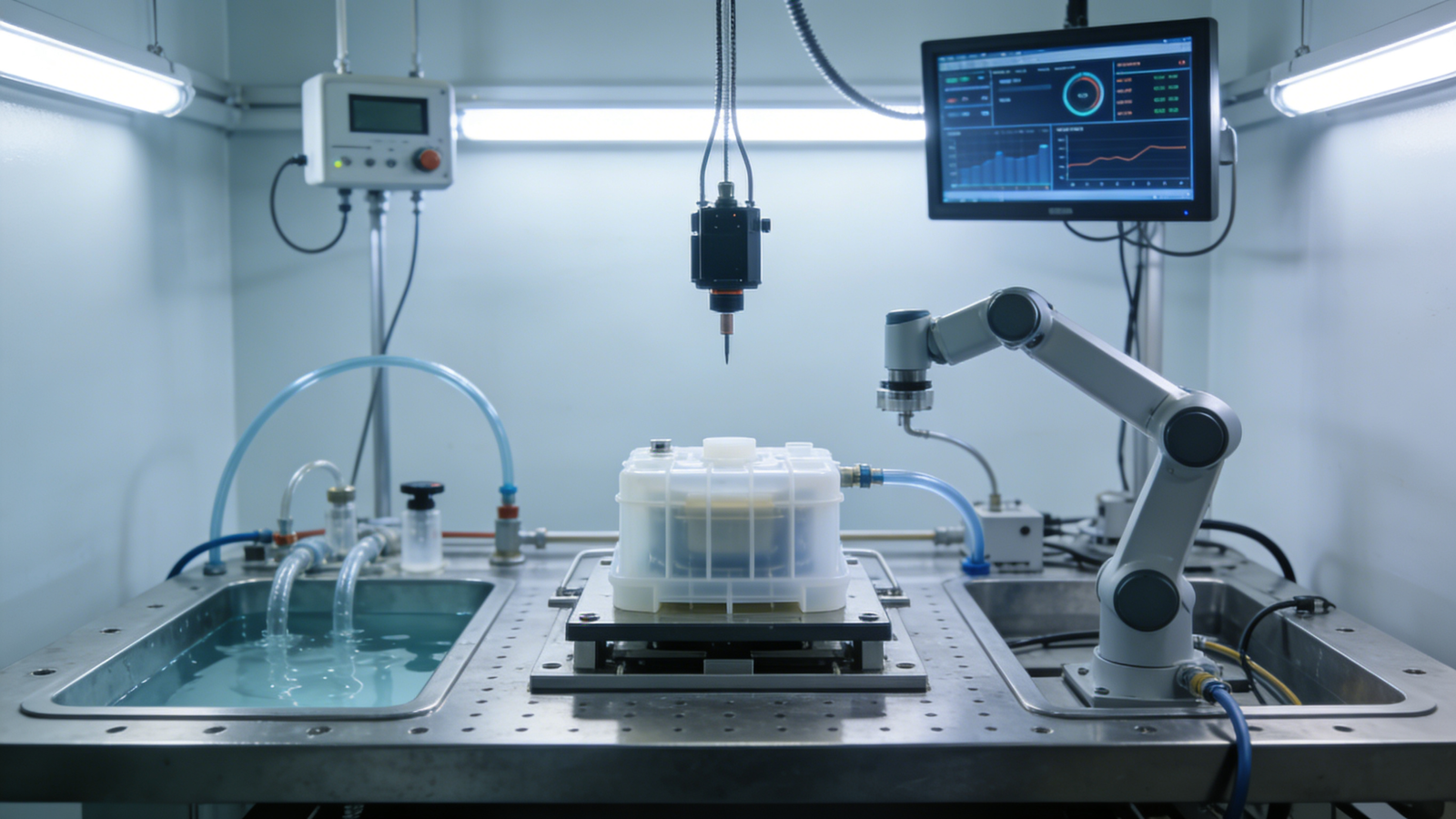

3.Process validation: Reduce mass-production risk through trial molds and pilot batches.

4.Stable delivery: Ensure long-term supply consistency with reproducible processes.

Frequently Asked Questions (FAQ)

Question 1: What are the core advantages of your PPS chemical-resistant injection molded parts?

Answer: Xiamen Ruicheng integrates PPS material stability with structural design and strict process control, ensuring corrosion resistance is validated under real operating conditions.

Question 2: What information is required to start sourcing PPS corrosion-resistant injection molded parts?

Answer: Media type, operating temperature range, component drawings, and expected service life enable us to complete a preliminary feasibility evaluation within 12 hours.

Question 3: What are the MOQ and lead times for different order volumes?

Answer: Low-volume pilot production is supported for validation, while standard mass production lead times are typically 15–20 days and adjustable to project schedules.

Question 4: How are quality or dimensional issues handled after delivery?

Answer: Xiamen Ruicheng provides full traceability and re-inspection mechanisms, offering replacement or process optimization once issues are confirmed.

Question 5: Can you support customization for special chemical operating conditions?

Answer: Yes, we support customization for high-temperature, high-corrosion, or complex structural requirements, with clear timelines and cost implications defined upfront.

Conclusion

The value of PPS chemical-resistant injection molded parts in chemical equipment corrosion protection lies in their long-term compatibility with complex operating conditions rather than isolated material metrics. With proper component selection and injection molding strategies, companies can significantly reduce maintenance frequency and improve equipment reliability. Only by selecting PPS injection molded parts from an application-driven perspective can their full engineering value be realized.

For expert assistance in implementing PPS chemical-resistant injection molded parts for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!