Introduction

As a high-performance engineering plastic, PEEK is increasingly used in environments involving sustained heat, chemical exposure, and mechanical loads. In injection molded parts manufacturing, its long-term thermal stability directly determines whether components can reliably support continuous equipment operation rather than short-term testing conditions. More manufacturers are now shifting their focus from nominal heat resistance values to real-world, long-duration performance.From Xiamen Ruicheng’s practical project experience, the long-term heat resistance of PEEK injection molded parts depends on the combined alignment of material systems, process control, and application scenarios.

In high-end equipment, semiconductor manufacturing, medical devices, and aerospace-related applications, PEEK molded components are often required to maintain dimensional and mechanical stability under continuous high temperatures.What truly defines whether PEEK parts can “withstand long-term heat” is not a single material parameter, but a systematic injection molding and application engineering capability.

Are PEEK injection molded parts truly suitable for long-term high-temperature environments?

The performance of PEEK injection molded parts under continuous high-temperature conditions is not determined solely by the material’s heat resistance rating, but is closely related to crystallinity control, residual stress management, and applied mechanical loads. Properly engineered PEEK molded components can maintain stable performance in environments exceeding 200 °C over extended periods. At Xiamen Ruicheng, we combine PEEK material characteristics with optimized high-temperature injection molding processes to reduce thermal aging risks. When supported by validated process control, PEEK injection molded parts are capable of long-term heat resistance rather than short-term thermal tolerance. This capability directly addresses the core concerns of high-end equipment manufacturers.

Thermal material foundation: PEEK’s high glass transition and melting temperatures provide an inherent base for long-term thermal stability.

Process stability control: Precise mold temperature and cooling rate management supports a stable crystalline structure.

Structural load alignment: Rational design disperses stress and reduces creep risks at elevated temperatures.

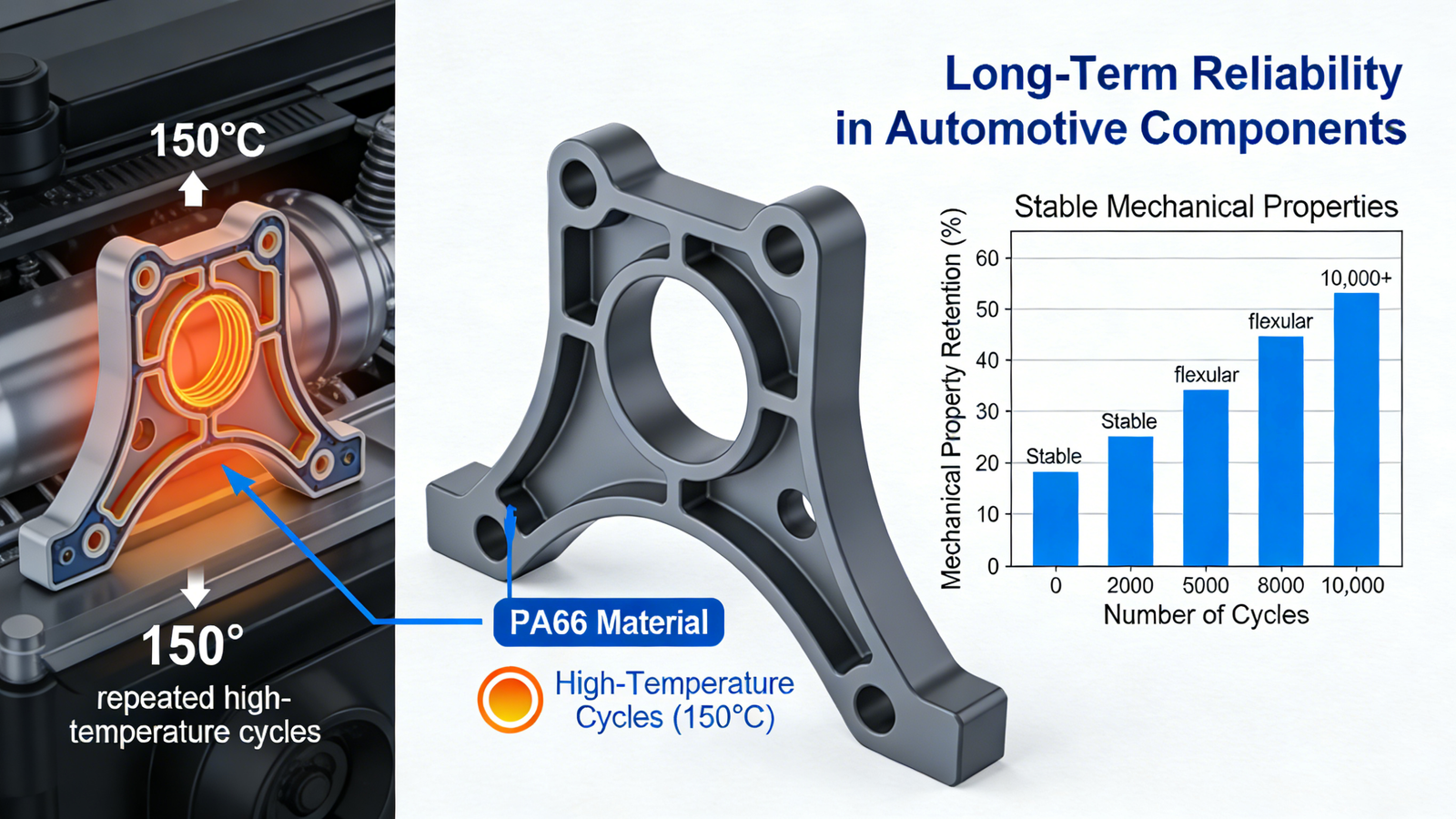

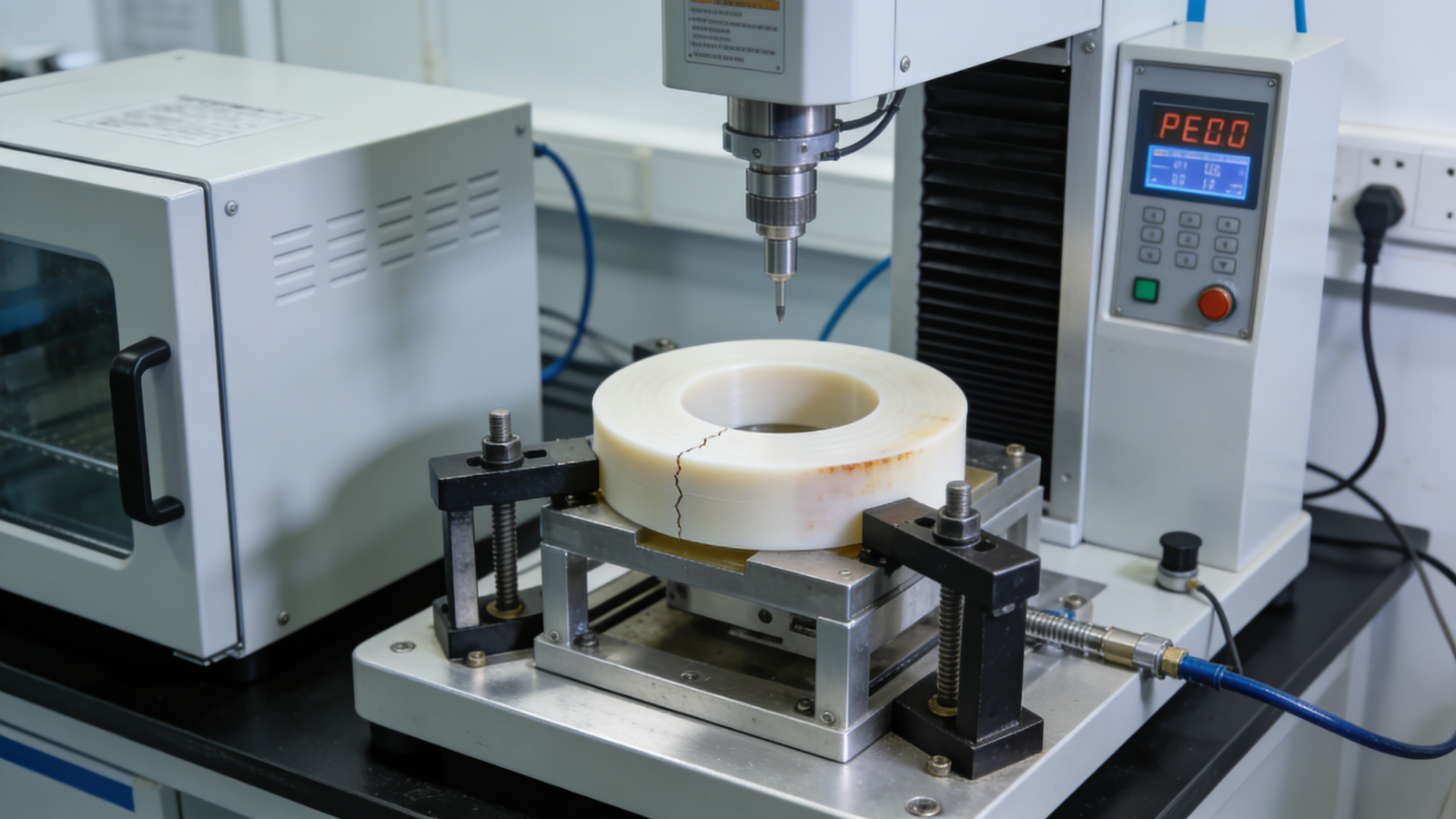

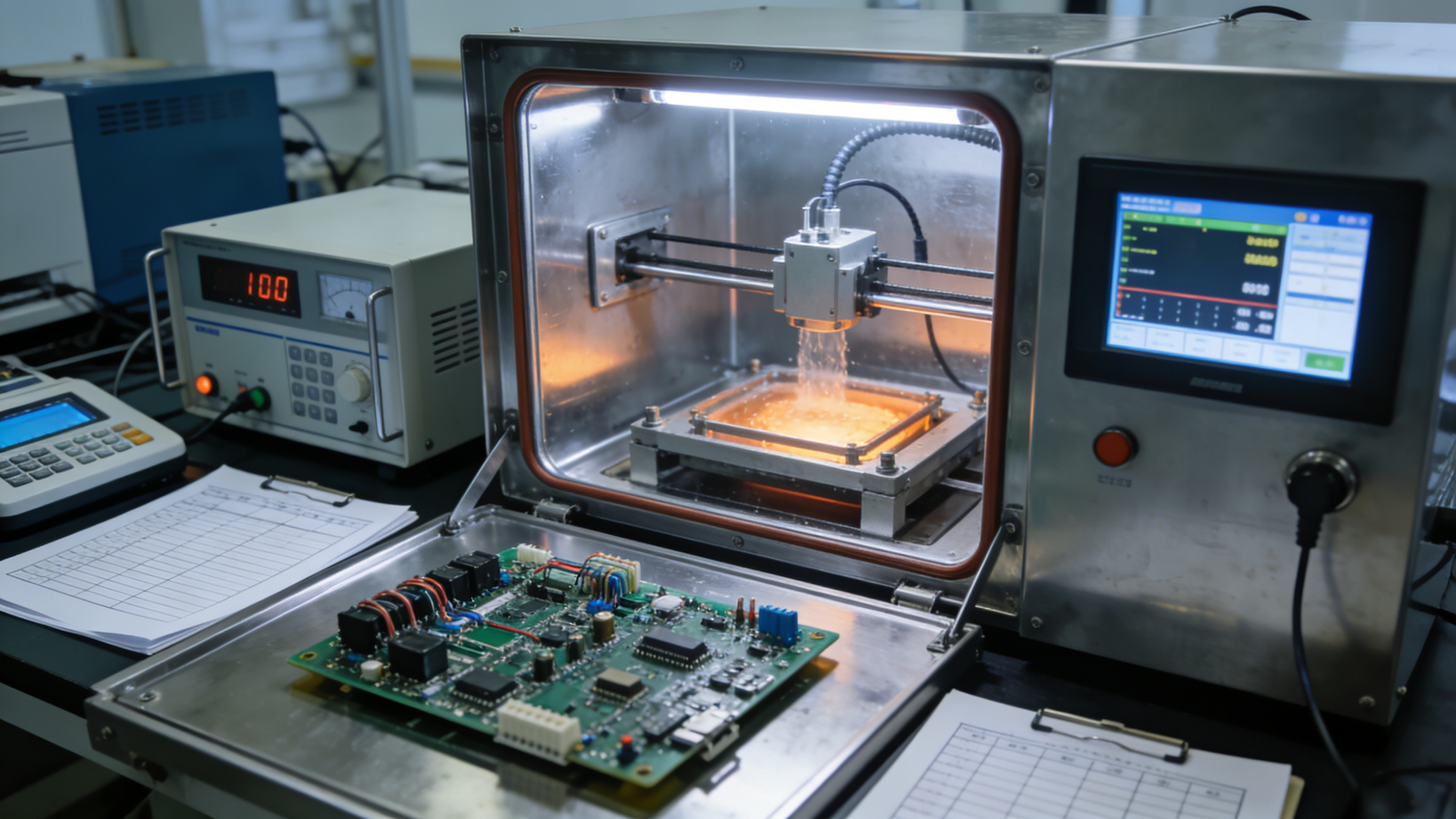

Application-level validation: Simulated operating-condition aging tests confirm long-term reliability.

🔥 For PEEK, long-term heat resistance is a system-level outcome, not a single material advantage.

Will PEEK injection molded parts experience performance degradation under prolonged heat exposure?

Under sustained high-temperature conditions, PEEK molded parts may experience mechanical or dimensional changes if they are not properly designed or processed. However, these risks can be effectively controlled through appropriate material grade selection and process optimization. At Xiamen Ruicheng, we routinely validate long-term performance using thermal aging tests combined with engineering plastic heat resistance evaluations. When injection parameters and application conditions are properly matched, PEEK maintains reliable performance even under long-term heat exposure. This is a key reason why experienced processors are preferred by B2B buyers.

Thermal aging influence: Prolonged heat may cause molecular relaxation, which can be mitigated through material grade selection.

Dimensional stability risk: Thermal cycling amplifies residual stress, making process control critical.

Performance retention strategy: Optimized crystallinity slows down performance degradation.

Verification and traceability: Long-term test data supports procurement decisions and reduces application risks.

🧠 The long-term stability of PEEK is built on verifiable processing and testing systems.

Which application scenarios truly require long-term heat-resistant PEEK injection molded parts?

Not all high-temperature environments justify the use of long-term heat-resistant PEEK injection molded parts, but their value becomes evident in scenarios involving continuous operation, high downtime costs, or strict safety requirements. At Xiamen Ruicheng, we evaluate necessity by combining high-temperature industrial applications with tailored injection molding solutions. When equipment must operate reliably under heat for extended periods, PEEK injection molded parts often deliver superior lifecycle value.

Continuous-operation equipment: Semiconductor tools and high-temperature testing systems demand extreme stability.

High-reliability components: Medical and aerospace-related parts cannot tolerate performance failure.

High-temperature chemical environments: PEEK excels where heat and chemical exposure coexist.

Lifecycle-driven selection: Focus shifts from material cost to total service life.

🚀 Applications that truly require PEEK prioritize long-term reliability over short-term heat resistance.

Reference Comparison of Long-Term Heat Resistance in Injection Molded Materials

| Comparison Dimension | PEEK Injection Parts | PPS Injection Parts | High-Temp PA | PI Materials |

|---|---|---|---|---|

| Continuous Heat Resistance | High | Medium | Medium–Low | Very High |

| Dimensional Stability | Excellent | Good | Average | Excellent |

| Long-Term Aging Performance | Stable | Controllable | Prone to degradation | Stable |

| Injection Molding Feasibility | Mature | Mature | Mature | Limited |

If you are evaluating which material best fits long-term high-temperature requirements, consider discussing real operating conditions with us directly: contact us

Xiamen Ruicheng’s Perspective on Long-Term Heat Resistance in PEEK Injection Molding

Whether PEEK injection molded parts can withstand long-term heat fundamentally depends on whether the manufacturer has systematic engineering capability rather than just equipment or material access. At Xiamen Ruicheng, every PEEK project follows a closed-loop process from design evaluation and mold structure optimization to process window definition and validation testing. This application-result-oriented manufacturing logic is what truly supports customer expectations for long-term thermal reliability.

1.Requirement identification: Define continuous operating temperature, load, and service life targets.

2.Process alignment: Adjust injection and mold temperature strategies for high-temperature materials.

3.Process validation: Verify long-term stability through functional and aging tests.

4.Production assurance: Ensure batch consistency and traceability in mass production.

Frequently Asked Questions (FAQ)

Question: What is the core advantage of your PEEK high-temperature injection molding service?

Answer: Xiamen Ruicheng combines stable high-temperature process control with real application aging validation to ensure that PEEK components maintain performance under continuous heat exposure.

Question: What information is required to start a PEEK injection molding project?

Answer: We typically require operating temperature range, continuous runtime expectations, structural drawings, and target service life to quickly assess feasibility and propose process solutions.

Question: What are the delivery timelines for different order volumes?

Answer: For small-batch validation and mass production, we offer flexible scheduling. Samples are typically delivered within 7–10 working days, with production timelines confirmed based on part complexity and volume.

Question: How are long-term performance issues handled after delivery?

Answer: Xiamen Ruicheng provides technical analysis and corrective support based on application scenarios, with process adjustments or improvements implemented once responsibility is confirmed.

Question: Do you support customization for special high-temperature operating conditions?

Answer: Yes, we support customization of material grades, structural design, and processing strategies based on specific thermal, mechanical, and environmental requirements.

Conclusion

Whether PEEK high-temperature injection molded parts can withstand long-term heat exposure depends not on material labels but on a deep understanding of continuous-use conditions. Through systematic material selection, process control, and validation, PEEK injection molded components can reliably perform in sustained high-temperature environments. From Xiamen Ruicheng’s experience, long-term heat resistance is a capability that can be engineered and verified, not a vague performance claim. This is the core value procurement teams should evaluate when selecting a PEEK injection molding partner.

For expert assistance in implementing solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!