Introduction

Equipment maintenance procurement often suffers from budget overruns caused by frequent part replacement and unplanned downtime, while the selection of injection molded parts directly determines long-term maintenance costs. Shifting from one-time purchase thinking to full life-cycle cost control is the core path to maintenance cost reduction.

From the perspective of Xiamen Ruicheng, injection molding is not only about materials and parameters, but about real operating conditions, failure modes, and sustainable supply capability. Through early-stage material selection and process coordination, maintenance costs can be effectively controlled before mass production.

Which Injection Molded Parts Should Be Prioritized Under High Maintenance Costs?

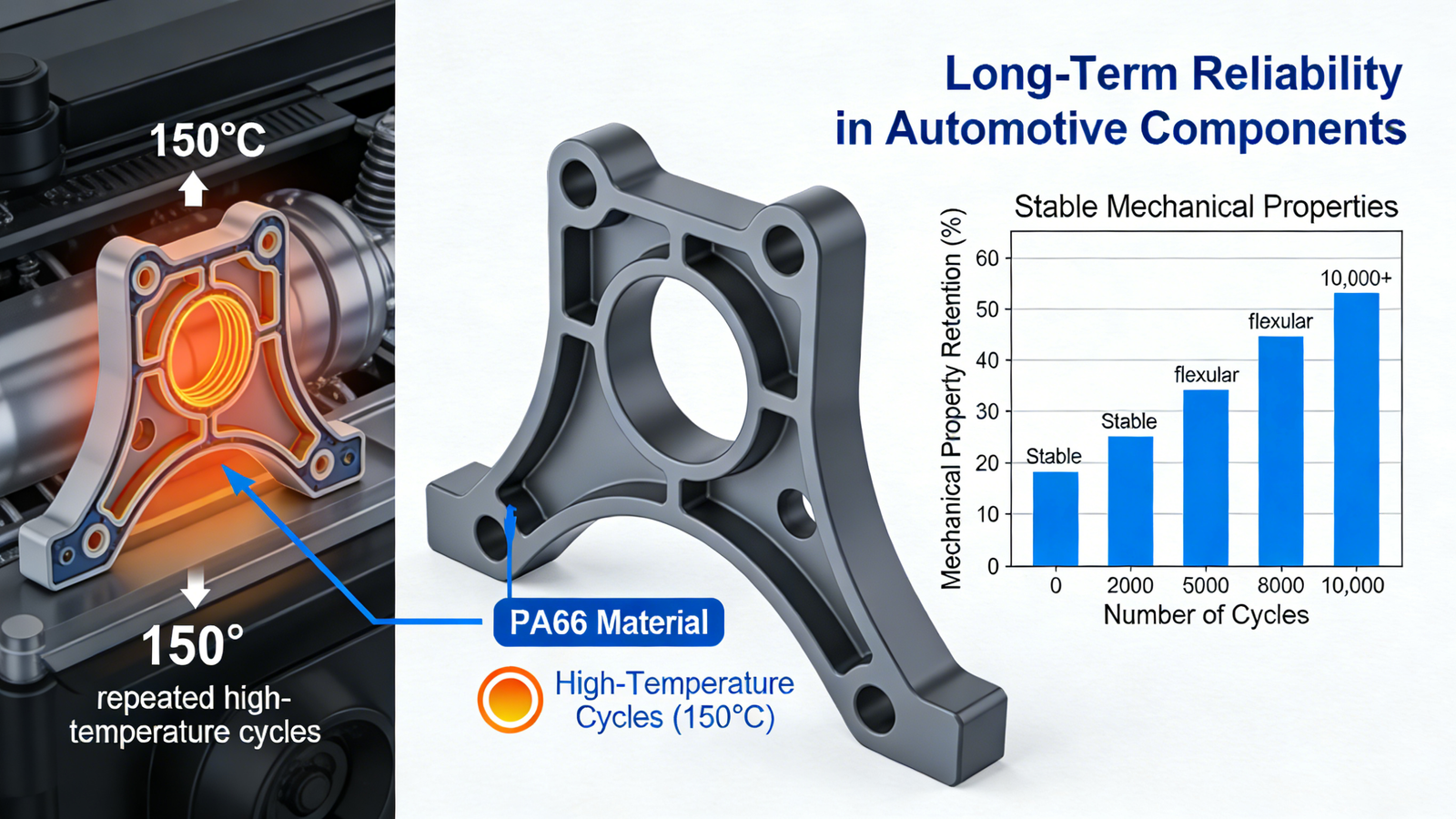

In equipment maintenance scenarios, frequent wear, chemical exposure, and thermal fatigue are the main causes of cost escalation, and the right choice of engineering plastics and structural design can significantly extend replacement intervals. At Xiamen Ruicheng, we leverage engineering plastics and wear-resistant injection molded parts to reduce maintenance frequency through material screening and molding stability. Only by aligning selection with real loads instead of parameter stacking can true cost reduction be achieved.

Material Durability: Matching high wear and fatigue resistance to actual load conditions reduces unplanned downtime.

Structural Optimization: Stress distribution is optimized during injection molding to prevent early crack propagation.

Process Stability: A stable molding window ensures batch consistency and reduces maintenance uncertainty.

Supply Continuity: Long-term mold and raw material management ensures continuous spare part availability.

🔧 Systematic selection from material to process is the first step in controlling maintenance costs.

How Can Life-Cycle Design of Injection Molded Parts Reduce Long-Term Maintenance Expenses?

Equipment maintenance is not a one-time issue but a continuous investment throughout the equipment’s life cycle, and life-oriented design balances initial procurement and long-term maintenance costs. At Xiamen Ruicheng, we integrate life-cycle assessment with injection molding to move maintenance decisions upstream into the design phase. This approach aligns procurement decisions with real usage scenarios.

Life Prediction: Safety factors are set based on operating data to avoid over- or under-design.

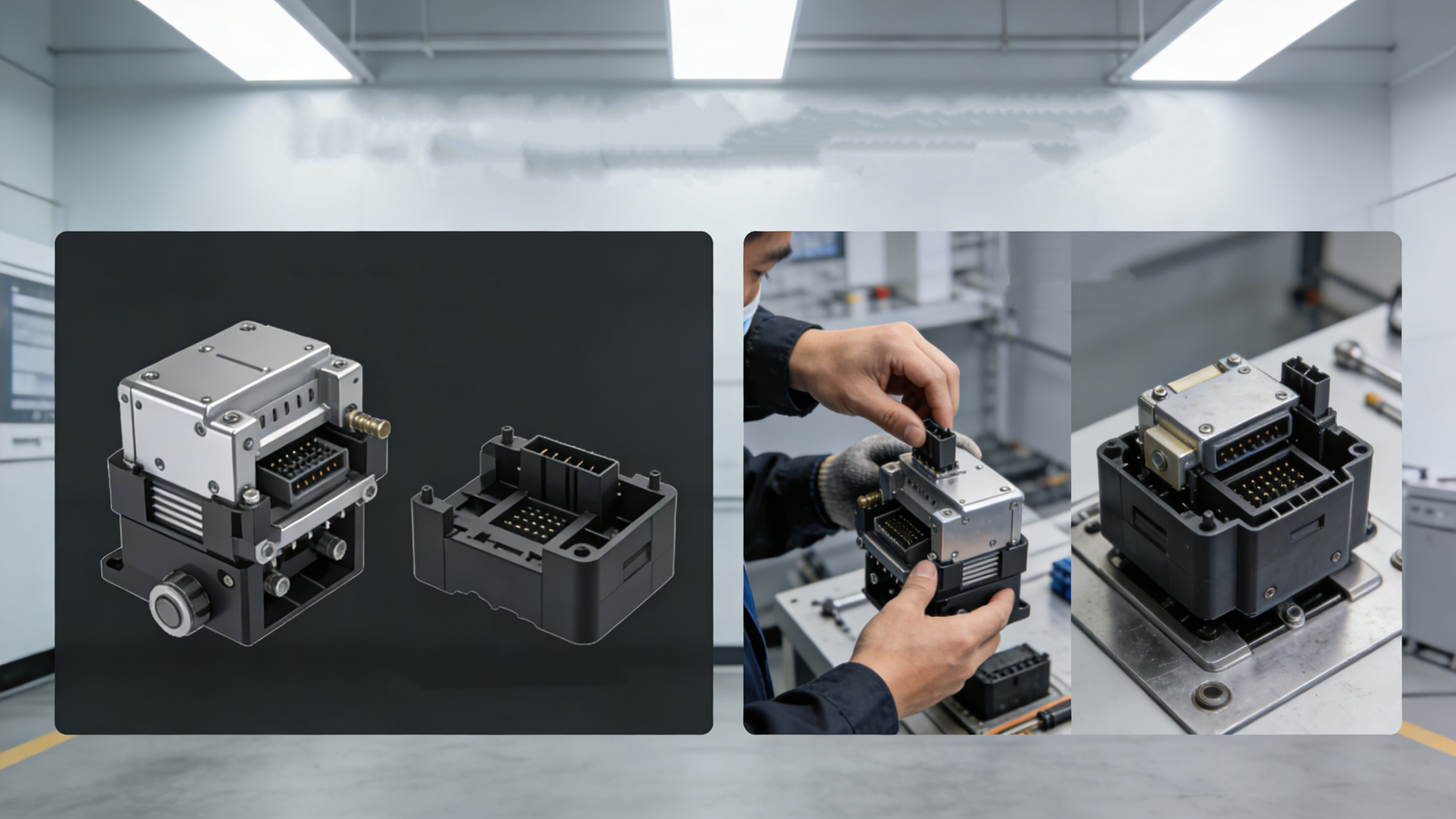

Replaceability: Modular injection molded part design shortens maintenance time and lowers labor costs.

Consistency Control: Process monitoring minimizes abnormal wear caused by batch variation.

Verification Testing: Accelerated life testing before mass production reduces downstream risk.

⏳ Life-cycle design turns maintenance from reactive spending into controlled investment.

How Can Maintenance Procurement Avoid Repeated Replacement Caused by Poor Part Selection?

Selection mistakes often result from a disconnect between parameters and real operating conditions, leading to repeated early failures of injection molded parts. Xiamen Ruicheng emphasizes early communication with procurement teams through material selection and failure analysis. Scenario-based validation significantly reduces trial-and-error costs.

Condition Simulation: Selection validation is based on actual temperature, media, and load conditions.

Risk Front-Loading: Potential failure modes are exposed during the sample stage.

Collaborative Review: Engineering and maintenance teams jointly participate in decision-making.

Data Accumulation: Historical maintenance data is converted into reliable selection references.

⚠️ Correct selection saves far more budget than frequent replacement.

Maintenance Cost Comparison and Selection Reference for Injection Molded Parts

| Comparison Dimension | Standard Plastics | Engineering Plastics | Optimized Structures | Xiamen Ruicheng Solution |

|---|---|---|---|---|

| Service Life | Short | Medium | Long | Long |

| Replacement Frequency | High | Medium | Low | Low |

| Downtime Risk | High | Medium | Low | Low |

| Total Maintenance Cost | High | Medium | Low | Low |

Want to know which solution best fits your maintenance scenario? Feel free to contact us

Upgrading Maintenance Procurement From Product Display to Decision Support

Maintenance procurement should not stop at product display, but should cover the entire decision chain before, during, and after purchasing. Xiamen Ruicheng delivers solution-oriented injection molding services to help buyers lock in maintenance costs early.

1.Requirement Analysis: Reverse-engineering materials and structures from maintenance pain points.

2.Solution Validation: Samples and testing run in parallel to reduce decision risk.

3.Mass Production Coordination: Stable processes ensure long-term consistency.

4.Continuous Support: Maintenance feedback data drives next-round optimization.

Frequently Asked Questions (FAQ)

Question 1: What are your core advantages in reducing maintenance costs with injection molded parts?

Answer: We combine material durability, structural life design, and stable process control, quantifying replacement cycles and failure rates so maintenance costs can be evaluated at the procurement stage.

Question 2: What information is required to initiate procurement and quotation?

Answer: Please provide operating conditions, environmental media, load frequency, and expected service life. We deliver selection recommendations and quotations within 12 hours.

Question 3: What are your delivery timelines for different order volumes?

Answer: Small-batch trial production is supported, with standard mass production delivery in 7–10 days. Urgent orders can be supported via flexible production lines.

Question 4: How are quality or life-span issues handled after delivery?

Answer: Reinspection is supported within 7 days of receipt. Once responsibility is confirmed, replacement or technical optimization is arranged within 48 hours.

Question 5: Do you support customized solutions for special maintenance conditions?

Answer: Yes. We provide material or structural customization based on specific conditions, with timelines and costs communicated transparently in advance.

Conclusion

When facing high maintenance costs, equipment procurement should not focus solely on unit price, but on real operating conditions and full life-cycle performance. By partnering with an injection molding manufacturer like Xiamen Ruicheng, maintenance costs can be effectively controlled at the design stage. When selection, process, and supply form a closed loop, maintenance shifts from a cost center to a pillar of stable operation.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!