Introduction

The blend ratio of PC/ABS alloy significantly impacts the reliability, aesthetic stability, and long-term performance of electronic devices during structural design and casing selection. At Xiamen Ruicheng, we have found that missteps in ratio selection often stem not from material performance issues, but from insufficient understanding of device application scenarios.

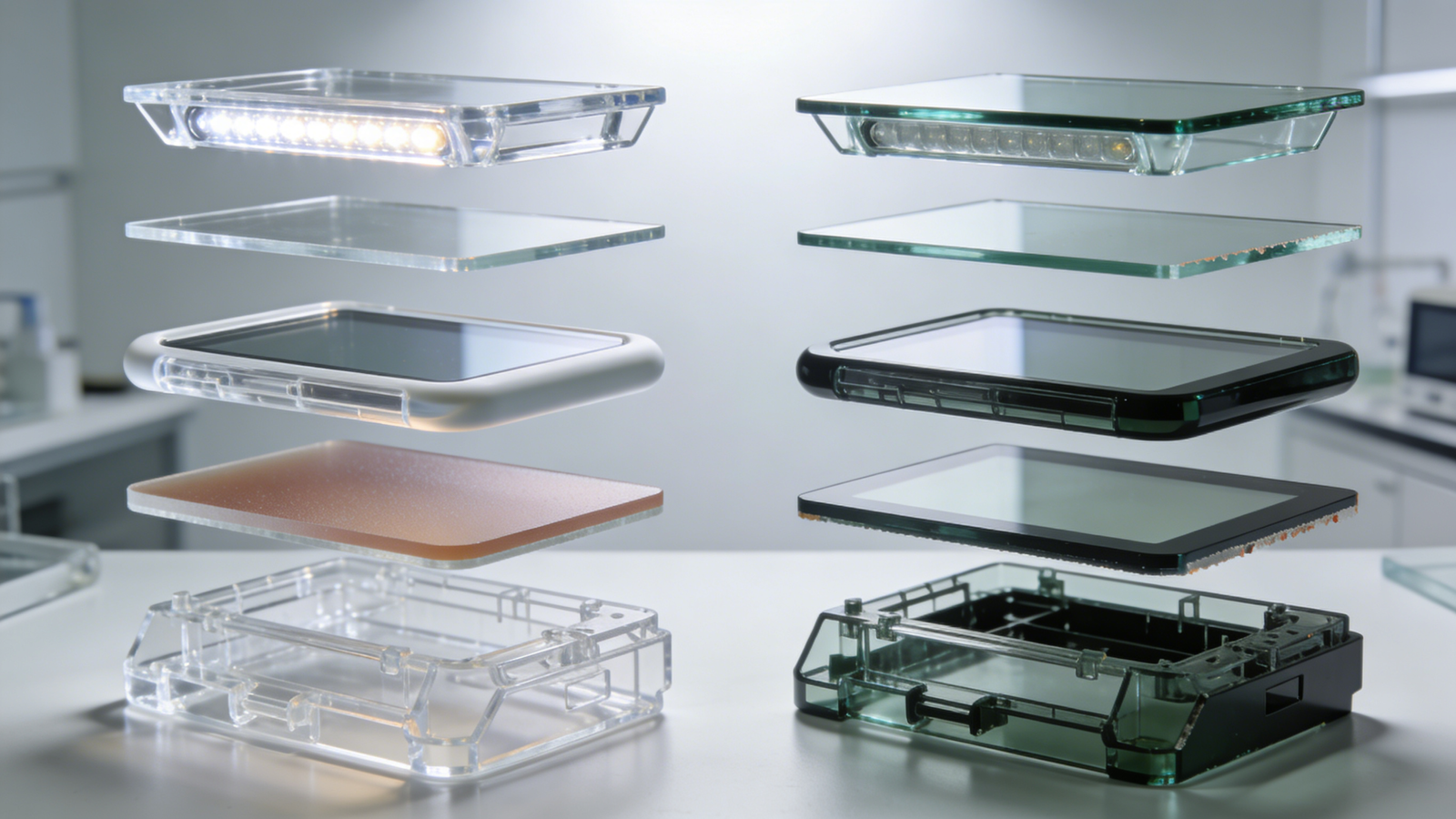

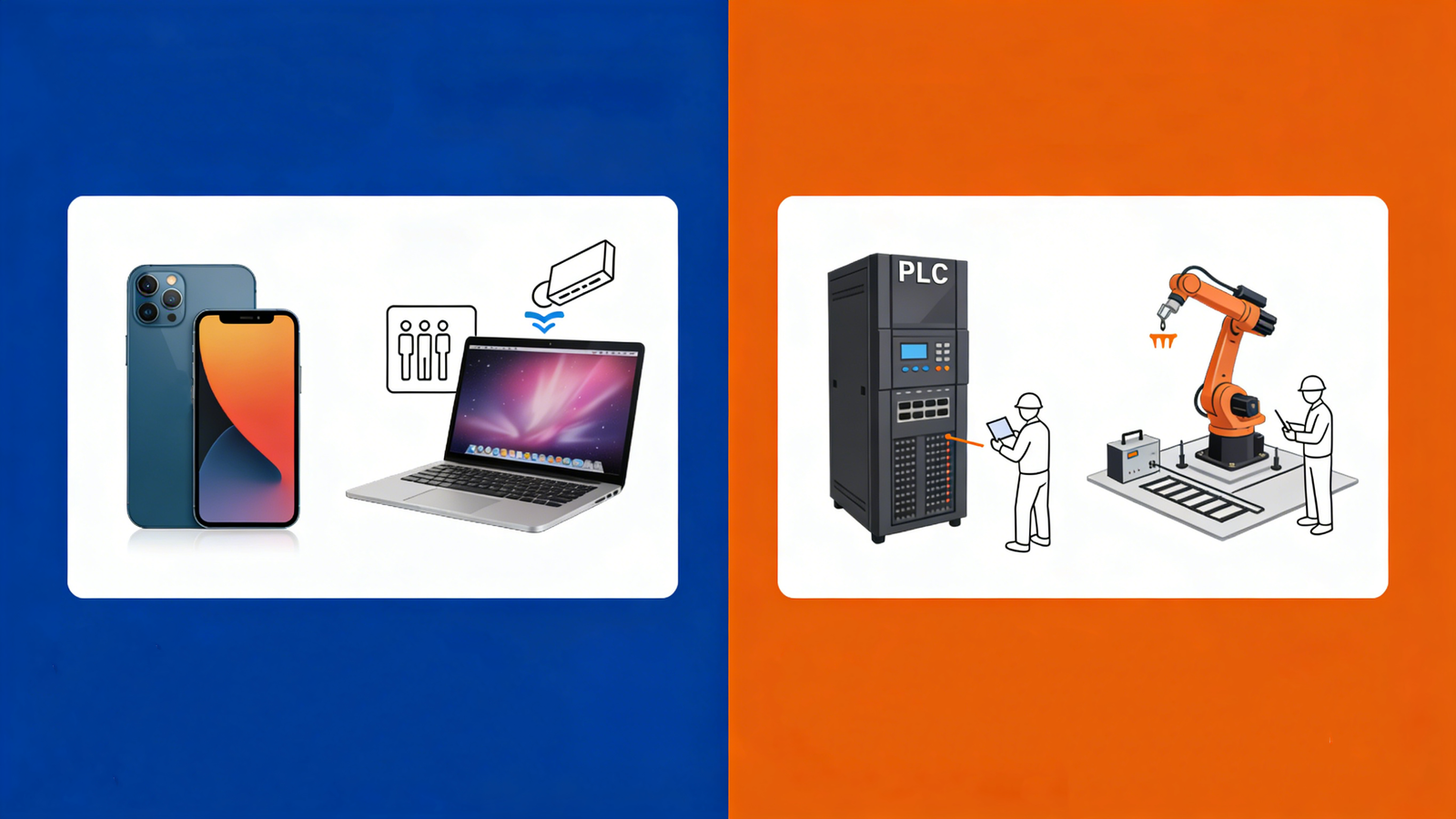

From consumer electronics to industrial control devices, different equipment focuses on different priorities in terms of heat resistance, impact resistance, and visual consistency. Early involvement in ratio customization during the decision-making phase can effectively reduce the risk of mold rework and corrections, which is the core value of transitioning from "product display" to "decision-making support."

What are the differences in PC/ABS ratio priorities across different electronic devices?

Different types of electronic devices exhibit significant differences in usage environment, expected lifespan, and assembly methods, making the customization of the PC/ABS blend ratio essential. At Xiamen Ruicheng, we reverse-engineer material structures based on application scenarios, avoiding sole reliance on material specifications. The real operating conditions of the device are the core consideration in determining the priority of the PC/ABS blend ratio, such as industrial equipment focusing more on heat resistance rather than surface gloss, while consumer electronics prioritize impact resistance and visual consistency.

Usage Environment: Devices exposed to high temperatures or confined spaces require a higher PC proportion for structural stability.

Mechanical Load: Parts subject to frequent assembly/disassembly or stress rely more on the impact-resilient properties of ABS.

Aesthetic Requirements: Devices with higher aesthetic demands need to balance the flowability of ABS and the rigidity of PC.

Assembly Methods: Snap-fit and thin-wall structures benefit from a ratio that favors the toughness of ABS.

🔧 Distinguishing device types is the first step in customizing the PC/ABS ratio.

How does the PC/ABS ratio affect injection molding stability?

During injection molding, variations in the PC/ABS ratio directly affect melt flow, molding window, and yield control. At Xiamen Ruicheng, we customize ratios to match mold structures and production cycle requirements. The ratio is not necessarily better when higher performance is achieved, but it should be aligned with molding conditions, such as a higher PC ratio improving heat resistance but potentially increasing internal stress during molding, affecting injection molding stability. Additionally, changes in ABS ratio impact surface quality and demolding performance.

Flow Behavior: An increase in ABS ratio helps stabilize thin-wall filling.

Shrinkage Control: Adjusting the PC ratio can reduce dimensional fluctuations but requires mold temperature management.

Internal Stress: An imbalanced ratio may cause cracking issues in later stages.

Yield Management: A consistent ratio helps shorten machine tuning time and maintain batch consistency.

⚙️ Molding stability determines whether the ratio customization can truly be implemented in mass production.

How to determine the optimal ratio between cost and performance?

In the decision-making process for electronic device procurement, balancing material cost with performance is often critical, and the PC/ABS ratio is a key lever for cost control. At Xiamen Ruicheng, we help clients clearly define which performance characteristics are "non-negotiable" and which can be compensated for by structural design. The truly cost-effective ratio plan comes from clearly ranking the priorities of needs, rather than simply reducing the PC content or chasing high-performance labels. By evaluating material costs and product lifecycle, the ratio plan can remain sustainable during mass production.

Critical Performance Needs: Confirm whether heat resistance or impact resistance is a non-negotiable requirement.

Structural Compensation: Optimize rib placement and wall thickness to reduce reliance on high PC ratios.

Batch Size: Large-scale production suits a more stable and repeatable ratio plan.

Long-Term Supply: Avoid using rare ratios subject to supply volatility.

💡 Optimizing the ratio is about making procurement decisions more controllable.

Comparison of PC/ABS Ratios for Different Electronic Devices

| Device Type | Focus on PC Ratio | Focus on ABS Ratio | Key Considerations | Applicable Scenarios |

|---|---|---|---|---|

| Consumer Electronics | Medium | High | Aesthetics & Impact Resistance | Smartphones, Wearables |

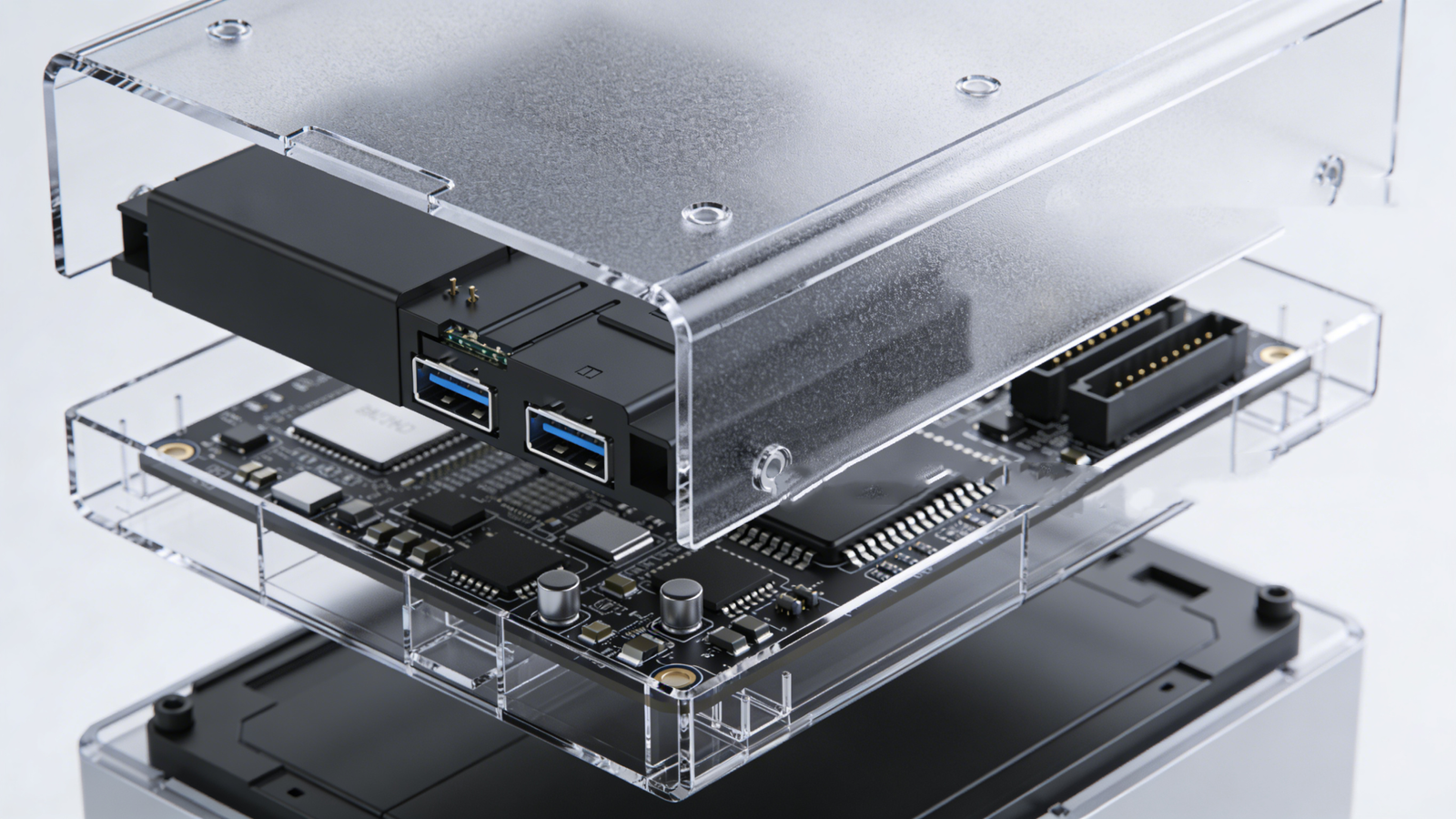

| Industrial Equipment | High | Medium | Heat Resistance & Dimensional Stability | Controller Housings |

| Medical Electronics | High | Low | Stability & Consistency | Diagnostic Equipment |

| Communication Equipment | Medium-High | Medium | Long-term Reliability | Routers, Base Stations |

Want to know which ratio suits your device best? Feel free to contact us

How Xiamen Ruicheng Supports PC/ABS Ratio Decision-Making

At Xiamen Ruicheng, we typically get involved in the material ratio assessment before design finalization, transforming demand clarification, sample validation, and mass production evaluation into a closed-loop process. We focus on whether the ratio decision can remain stable and feasible over the next three to five years, rather than achieving short-term optimization in parameters.

1.Demand Breakdown: Translate device usage scenarios into actionable material specifications.

2.Sample Validation: Verify the feasibility of the ratio through small batch trial molds.

3.Mass Production Evaluation: Ensure long-term stability by aligning with production line capabilities.

4.Risk Warning: Identify potential impacts on supply and delivery timelines due to ratio imbalances.

FAQ Module Title

Question 1: What are the core advantages of your PC/ABS ratio customization service?

Answer: We set the ratio baseline based on real application scenarios and production experience, ensuring stability in performance, processing, and supply to avoid discrepancies between theoretical parameters and actual usage.

Question 2: What information do we need to provide for the PC/ABS ratio customization project?

Answer: We recommend providing device usage details, structural drawings, and expected annual production volume. Xiamen Ruicheng can provide initial ratio suggestions and process feasibility analysis within 12 hours.

Question 3: How does order size affect lead time and MOQ for different quantities?

Answer: We support small batch verification during trial production, and MOQ varies based on the complexity of the ratio and annual demand, with regular delivery times ranging from 7–10 days.

Question 4: How do you handle performance mismatches after mass production?

Answer: We offer ratio review and process tracing mechanisms. After confirming issues, we can quickly adjust the plan and suggest alternative ratios.

Question 5: Do you support customized ratios for specific operational conditions?

Answer: Yes, we customize ratios based on parameters such as temperature, load, and usage frequency. The evaluation is completed within 3 working days, and the cost typically increases by 5%-15% over standard products.

Conclusion

The varying needs of different types of electronic devices for PC/ABS alloy ratios stem from differences in usage scenarios and risk tolerance. Xiamen Ruicheng helps clients transition from "parameter comparison" to "long-term controlled plans" through early ratio decision-making involvement. Ratio customization is not a one-time choice, but a continuous decision-making process throughout design to mass production. This is the long-term value we create for clients through our injection molding services.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!