Introduction

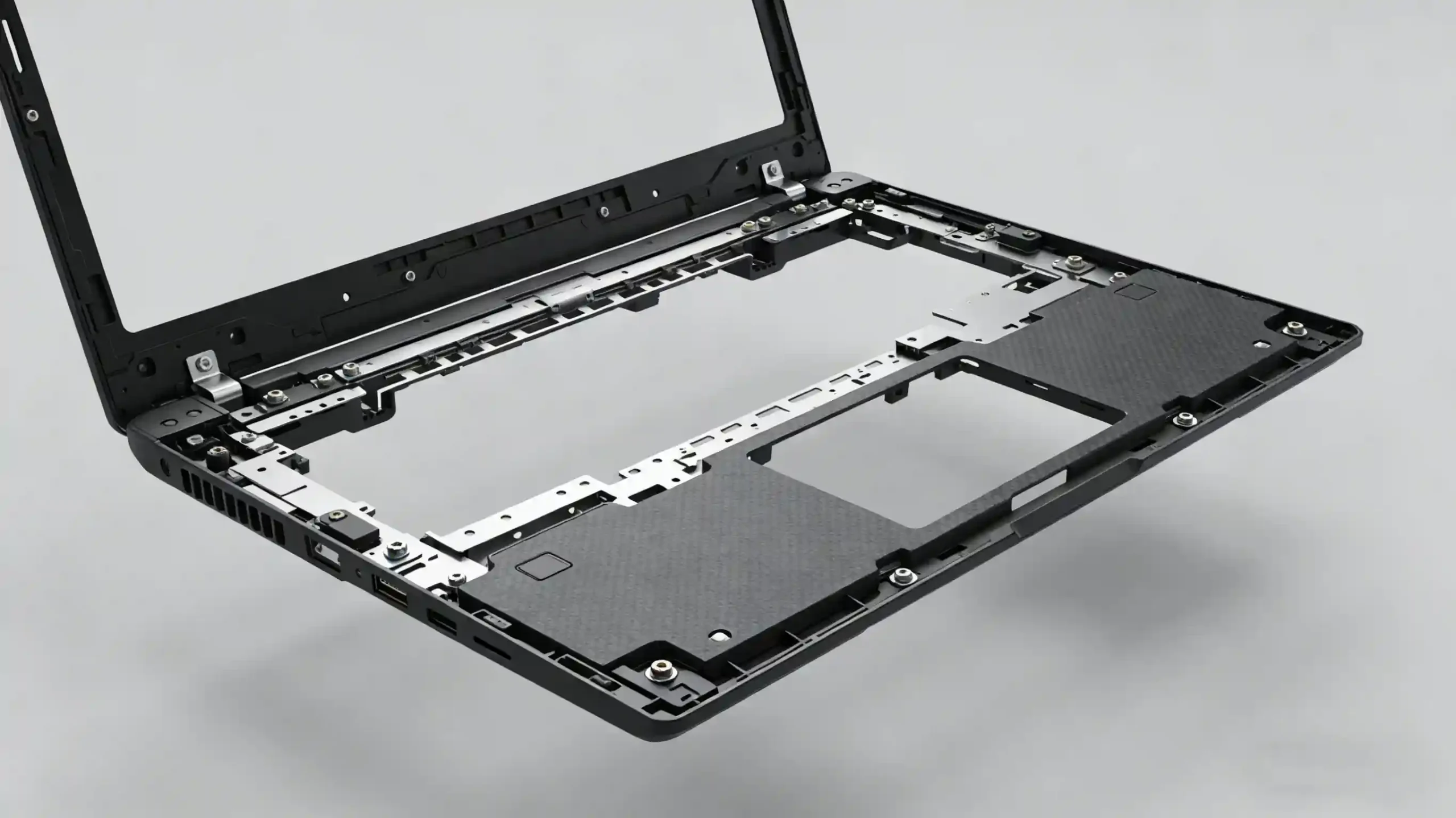

As laptops continue to evolve toward thinner, lighter, and more premium designs, the housing is no longer just a protective shell but a key contributor to product competitiveness. PC thin-wall injection molding provides a proven manufacturing route to reduce overall weight while maintaining structural integrity and visual refinement. Lightweight design today reflects manufacturing maturity rather than material compromise.

In real procurement decisions, buyers focus more on finished appearance, supply stability, and long-term consistency than on isolated material parameters. Xiamen Ruicheng leverages advanced PC thin-wall injection molding processes to deliver plastic housings with visual depth and tactile quality that can exceed metal solutions. True premium perception is ultimately determined by process stability and execution capability.

How Does PC Thin-Wall Injection Molding Truly Reduce Laptop Housing Weight?

PC thin-wall injection molding achieves weight reduction through optimized structural thinning and mechanical load redistribution, avoiding the secondary machining and assembly burdens common in metal housings. By utilizing the high strength-to-weight ratio of polycarbonate, housings maintain impact resistance even at reduced wall thickness, while injection molding enables one-piece forming that eliminates unnecessary components. When wall thickness control and melt flow design are balanced, lightweight outcomes become a natural result rather than a risk.

Structural integration: Ribs and shell surfaces are designed as a unified structure to support thin-wall regions under load.

Flow optimization: Gate and runner layouts ensure stable filling and uniform molecular orientation.

Part consolidation: Fewer metal reinforcements and fasteners directly reduce overall assembly weight.

Mass-production consistency: Mature processes keep weight and performance uniform across batches.

💡 Lightweight success depends on structural and process synergy, not extreme thinning alone.

Will Thin-Wall Design Compromise Strength and Durability?

In PC thin-wall injection molding, strength is determined less by thickness and more by material orientation and structural layout. By controlling polymer melt flow direction and cooling rates, local reinforcement zones are formed without increasing overall wall thickness. Well-engineered thin-wall designs often reduce residual stress and improve long-term durability.

Load distribution: Curved surfaces and ribs disperse impact forces during drops.

Material toughness: PC retains crack resistance even in reduced cross-sections.

Process window control: Stable molding parameters prevent brittleness caused by over-packing.

Lifecycle validation: Multi-stage durability testing confirms structural reliability.

🛡️ Durability comes from system-level design, not thickness accumulation.

How Can Plastic Housings Achieve a Premium Feel Beyond Metal?

Premium perception is not defined by metal alone but by the integration of visual uniformity, tactile feedback, and detail precision. PC thin-wall injection molding supports refined surface texture control and post-processing options while preserving lightweight advantages. When process stability is high, plastic housings often outperform metal in visual consistency.

Texture precision: Mold surface treatments produce fine, uniform textures without a plastic appearance.

Color stability: Optimized material-process matching prevents batch-to-batch variation.

Seamless integration: One-piece molding eliminates joints and gaps for a cleaner aesthetic.

Tactile enhancement: Coatings or micro-textures elevate hand feel and perceived quality.

✨ Premium quality results from repeatable manufacturing excellence.

Decision Comparison: PC Thin-Wall Injection vs. Traditional Housing Solutions

| Decision Factor | PC Thin-Wall Injection | Aluminum CNC | Magnesium Die Casting | Composite Materials |

|---|---|---|---|---|

| Part Weight | Lightest | Heavy | Medium | Light |

| Design Freedom | High | Medium | Medium | Low |

| Surface Consistency | Stable | Color variation risk | Oxidation risk | Hard to control |

| Cost at Scale | Controlled | High | High | High |

If you are evaluating which solution best fits your product positioning, feel free to reach out to us directly at contact us.

Extending from Product Display to Decision Partnership

PC thin-wall injection molding is not a single process but a system capability covering design, validation, and mass production. Xiamen Ruicheng participates early in project development to identify risks and optimize structures before tooling. Reducing decision cost means delivering executable solutions before problems emerge.

1.Early assessment: Evaluate thin-wall feasibility based on real application scenarios.

2.Process validation: Prototype under mass-production conditions.

3.Production assurance: Lock equipment and parameters for consistency.

4.Continuous optimization: Refine details based on market feedback.

Frequently Asked Questions (FAQ)

Question: What is the core advantage of your PC thin-wall laptop housings?

Answer: Our core strength lies in stable wall-thickness control and molding consistency, supported by advanced flow analysis and process monitoring to ensure lightweight structures without sacrificing durability.

Question: How can we start a customized housing project with your team?

Answer: Simply provide preliminary drawings or functional requirements. Xiamen Ruicheng will deliver a feasibility review and quotation with process recommendations within a defined response timeframe.

Question: How do lead times and pricing vary with order volume?

Answer: We support flexible transitions from pilot runs to mass production, offering scalable capacity and volume-based pricing strategies to keep project timelines predictable.

Question: How are consistency issues handled after mass production begins?

Answer: Batch traceability and process audits enable rapid root-cause analysis, with corrective actions or compensation implemented within agreed timelines.

Question: Do you support customized surface or tactile finishes?

Answer: Yes, we offer texture, color, and surface-effect customization within validated process limits, with cycle time and cost implications clarified during proposal stages.

Conclusion

PC thin-wall injection molding provides a mature pathway to achieve both lightweight design and premium perception for laptop housings. Through system-level engineering and stable manufacturing execution, plastic housings can reduce weight while exceeding metal alternatives in consistency and tactile quality. The real value lies in making lightweight design a foundation for brand elevation rather than a compromise. Xiamen Ruicheng enables this transition through full-process manufacturing capability and long-term supply reliability.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!