Introduction

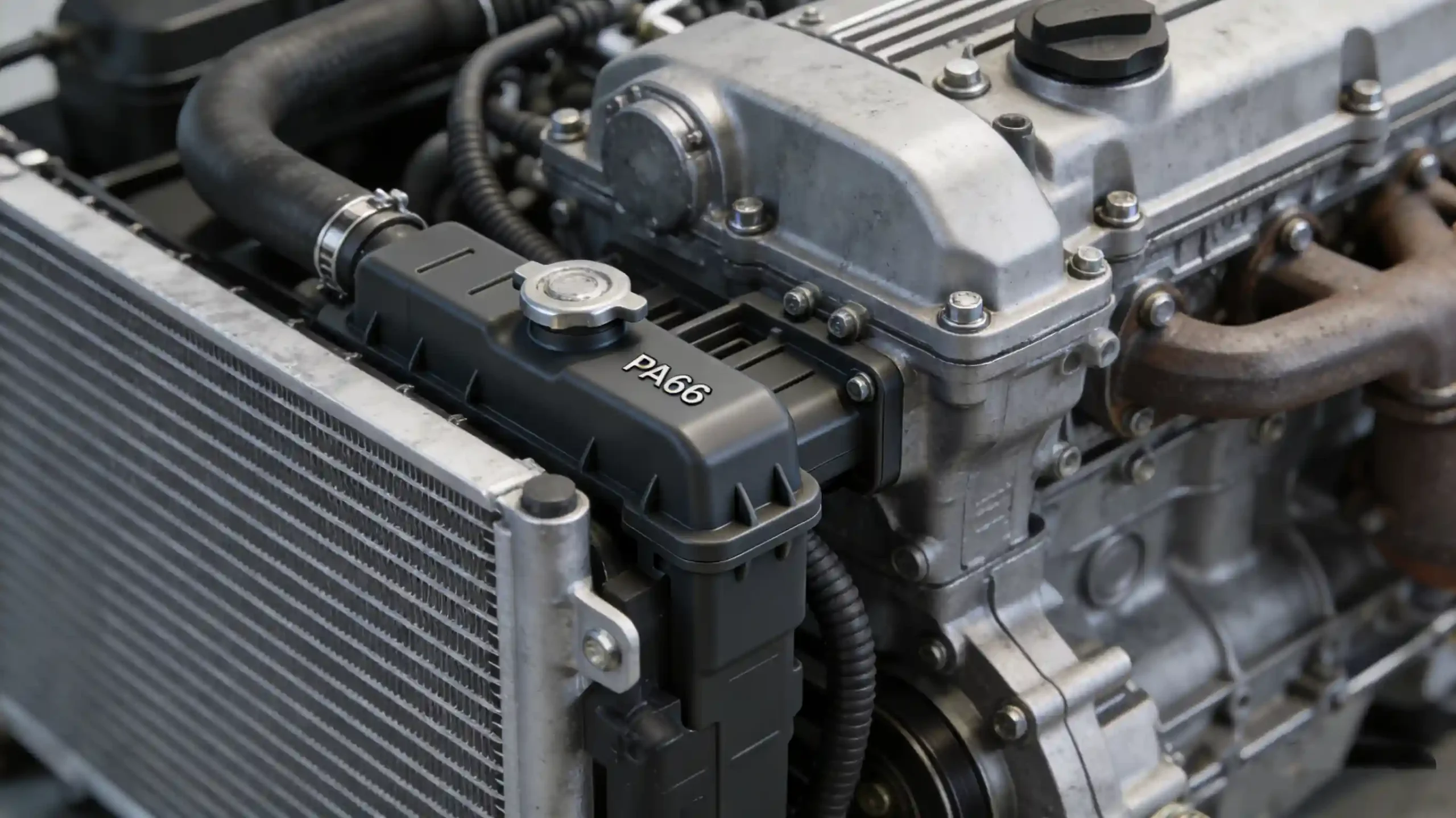

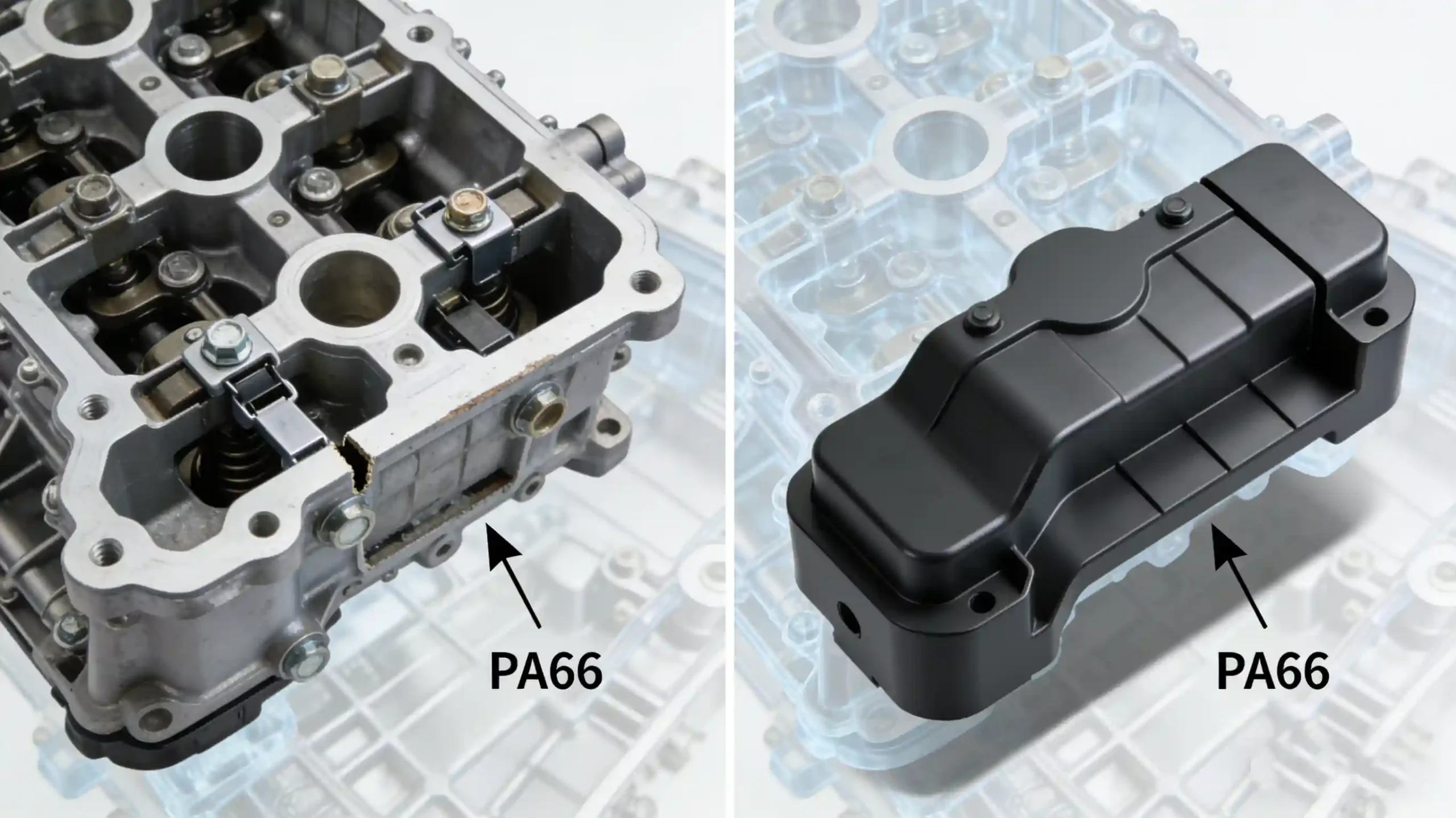

Engine components are increasingly designed with higher integration and lighter weight, making complex cavities and intricate geometries a standard requirement rather than an exception. Such complexity often leads to incomplete filling, visible weld lines, and dimensional instability during injection molding, directly impacting system reliability. Complex structures are placing unprecedented demands on material flow behavior and process stability.

PA66 injection molded parts are widely adopted in engine peripheral components due to their balanced flowability, mechanical strength, and thermal resistance. With proper mold design and process coordination, complex cavity filling becomes an engineered outcome rather than a trial-and-error risk. Material selection is now a decisive factor in overcoming complex filling challenges.

How Do PA66 Injection Molded Parts Address Insufficient Filling in Complex Engine Cavities?

In complex engine cavities, long flow paths and frequent cross-section changes often cause short shots when conventional materials are used. PA66 maintains continuous melt flow performance even in intricate structures, and its flow window can be further optimized through material modification, as detailed in PA66. When material flow behavior aligns with cavity geometry, filling challenges are systematically reduced. Combined with optimized injection molding parameters, filling risks can be effectively controlled.

Flow continuity: The melt front remains stable in long and thin flow paths, preventing premature freezing.

Shear response: Viscosity remains controllable under high shear, adapting to complex section transitions.

Process compatibility: Injection speed and packing profiles can be coordinated with material behavior.

Structural tolerance: Thin walls and rib features achieve higher filling reliability.

🙂 PA66 transforms complex cavity filling from uncertainty into controllability.

Do Complex Cavity Structures Increase Process Risks in PA66 Injection Molding?

Complex geometries inherently demand a narrower and more disciplined process window, where minor parameter deviations may amplify defect risks. PA66 offers strong thermal stability and predictable crystallization behavior, enabling a wider and more forgiving molding window even in complex cavities. With early-stage mold flow analysis, potential risks can be identified before tooling validation. By combining simulation with disciplined process control, complexity becomes a manageable variable rather than a production threat.

Thermal window: Stable flow is maintained across a wider melt temperature range.

Crystallization control: Dimensional changes during cooling are more predictable and compensable.

Simulation validation: Short-shot and weld-line risks are identified early.

Mass-production consistency: Batch-to-batch variation is effectively minimized.

🛠️ Complexity does not equal high risk when the right material and method are applied.

Can Choosing PA66 Injection Molded Parts Reduce Overall Manufacturing Costs for Engine Components?

Complex cavities are often associated with high scrap rates and repeated machine adjustments, which gradually inflate unit costs. The filling stability and dimensional consistency of PA66 injection molded parts reduce trial runs and rework frequency, while enabling structural integration through engineering plastics solutions. When yield improvement becomes consistent, complex designs can actually drive cost optimization. This outcome has been repeatedly validated by Xiamen Ruicheng in engine component programs.

Yield improvement: Scrap rates caused by insufficient filling are significantly reduced.

Setup efficiency: Stable process windows shorten machine tuning cycles.

Structural integration: Multi-part assemblies can be consolidated into single molded components.

Long-term value: Production cost curves become smoother and more predictable over time.

💡 True cost reduction comes from stability, not from simply lowering piece price.

Key Comparison Factors for PA66 Injection Solutions in Complex Engine Cavities

| Comparison Dimension | Conventional Materials | Modified PA66 | Optimized PA66 | Xiamen Ruicheng Solution |

|---|---|---|---|---|

| Complex filling capability | Average | Good | Excellent | Stable and controllable |

| Process window | Narrow | Medium | Wider | Wide and repeatable |

| Mass-production consistency | High variation | Controllable | Stable | Highly consistent |

| Total cost impact | Relatively high | Moderate | Optimized | Best long-term value |

When long-term yield and delivery stability become priorities, this decision point deserves deeper discussion, contact us

From Product Display to Decision Partnership in PA66 Injection Molding

The value of PA66 injection molded parts in complex cavity applications extends beyond material properties alone, encompassing full-cycle manufacturing decision support. Xiamen Ruicheng integrates early structural evaluation, mid-stage process validation, and long-term production support to convert material advantages into sustainable delivery capability. This transition from product display to decision partnership helps customers maintain certainty in complex purchasing decisions.

1.Early evaluation: Identify complex filling risks during the design stage.

2.Process validation: Synchronize trial molding with simulation-driven adjustments.

3.Production support: Establish stable process windows to ensure consistency.

4.Continuous optimization: Refine solutions based on real-world usage feedback.

Frequently Asked Questions About Procuring PA66 Injection Solutions for Complex Cavities

Question: What are the core advantages of your PA66 injection molded parts for complex cavity filling?

Answer: We define material flow grades and molding windows based on specific structural requirements, supported by mold flow analysis and process monitoring to ensure stable filling at cavity extremities.

Question: What information is required to initiate a customized PA66 injection project?

Answer: Complete drawings, operating conditions, and annual demand forecasts enable Xiamen Ruicheng to complete feasibility assessments and quotations within committed response timelines.

Question: How are MOQ and lead times handled across different order volumes?

Answer: Flexible strategies are applied for pilot runs and mass production, balancing validation needs with capacity assurance.

Question: How are filling or dimensional issues addressed after mass production begins?

Answer: Issues are assessed through established quality criteria, with corrective or replacement actions executed within agreed response periods.

Question: Do you support customized optimization for special structural requirements?

Answer: Yes, we provide dual-track material and process customization based on cavity complexity, with clear timelines and cost implications.

Conclusion

Complex cavity filling is no longer a single-variable challenge tied solely to material performance, but a system-level outcome of coordinated material, design, and process decisions. The application of PA66 injection molded parts in engine components demonstrates how informed selection can significantly reduce structural uncertainty. When manufacturing decisions are managed systematically, complexity itself becomes a competitive advantage. Through its decision-partnership approach, Xiamen Ruicheng ensures this advantage is consistently realized in mass production.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!