Introduction

Precision instruments place extremely high demands on gear dimensional stability, where even minor deviations can be amplified over long-term operation, ultimately leading to noise, efficiency loss, or system failure. For precision gears produced through injection molding, dimensional stability is never determined by a single parameter, but by the long-term interaction between material selection, mold design, and process control.

In real-world projects, many buyers discover that gears meeting initial inspection standards may still experience dimensional drift during service, and the real differentiation lies in a manufacturer’s ability to systematically control long-term stability risks. Xiamen Ruicheng supports customers through decision-stage collaboration, identifying and mitigating these risks early.

Why Do Injection-Molded Precision Gears Experience Dimensional Drift During Use?

After molding, precision instrument gears can still be influenced by environmental factors and residual internal stress, causing gradual dimensional changes that often appear only after assembly. Material crystallization behavior, molding shrinkage, and post-processing methods all have long-term effects, with injection molding and material shrinkage being critical yet frequently underestimated factors. Focusing solely on mold-cavity dimensions while ignoring long-term material behavior almost guarantees dimensional stability issues.

Residual stress: Rapid cooling during molding traps internal stress that is gradually released over time.

Environmental response: Temperature and humidity fluctuations amplify thermal expansion and moisture absorption effects.

Structural sensitivity: Gear roots and thin-wall areas are highly sensitive to micro-shrinkage.

Lack of stabilization: Without annealing or stabilization treatments, latent deformation risks remain.

⚙️ Understanding the root causes of dimensional drift is the first step toward stable precision gears.

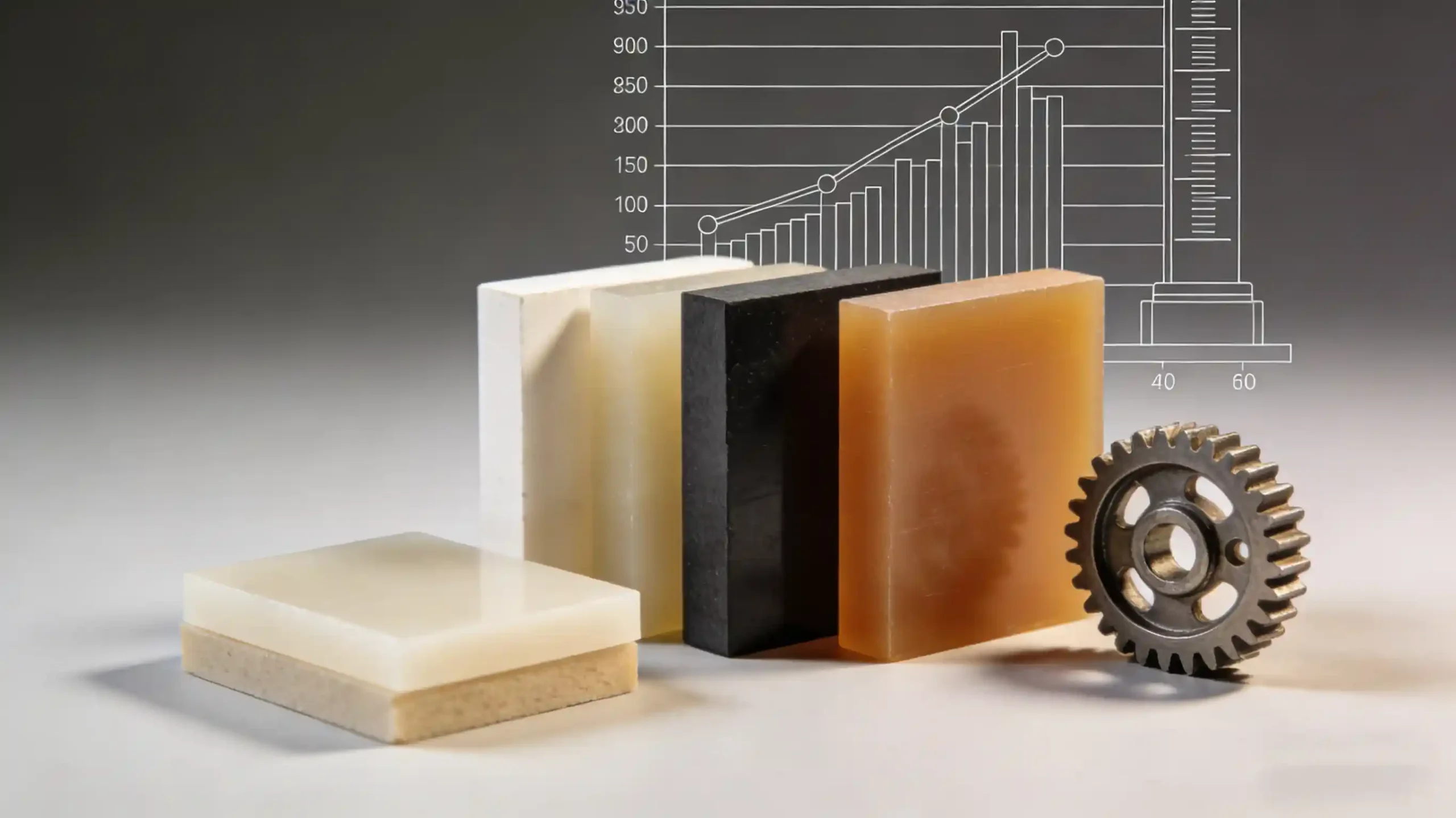

How Can Material Selection Improve Long-Term Dimensional Stability of Gears?

In precision instrumentation, materials are not selected merely for feasibility but for their ability to maintain geometry over long service cycles. Choosing engineering plastics with low moisture absorption and low creep, supported by systematic evaluation of engineering plastics and dimensional stability, helps avoid repeated post-assembly adjustments. Material selection decisions often determine whether a project is viable for mass production.

Moisture resistance: Low hygroscopic materials minimize dimensional fluctuation under varying environments.

Creep control: Maintaining shape under continuous load is non-negotiable for precision gears.

Formulation consistency: Stable resin batches ensure consistency across production lots.

Application validation: Simulating real operating conditions validates long-term material behavior.

🧩 Selecting the right material establishes a safety margin for dimensional stability.

How Does Injection Molding Process Control Affect Gear Dimensional Consistency?

Even with optimal materials, poor process control can still result in unstable dimensions. Melt temperature, packing pressure profiles, and cooling balance directly influence molecular orientation and crystallization, making injection molding parameters and mold temperature control decisive variables. A stable process window matters more than short-term machine tuning success.

Packing strategy: Proper packing pressure and time reduce post-mold shrinkage.

Balanced cooling: Uniform cooling minimizes warpage and localized dimensional deviation.

Process monitoring: Real-time parameter tracking prevents batch-to-batch variation.

Knowledge accumulation: Continuous project feedback refines process databases.

📐 Process stability is the invisible backbone of dimensional consistency.

Comparison of Dimensional Stability Control Strategies for Precision Gears

| Control Strategy | Stability Duration | Risk Level | Typical Application |

|---|---|---|---|

| Conventional molding | Short-term | High | Non-critical components |

| Material optimization | Mid-term | Medium | General precision needs |

| Enhanced process control | Mid–long term | Low | Precision instruments |

| Integrated system approach | Long-term | Very low | High-end precision systems |

If you are evaluating which solution fits your application, now is the right time to consult a professional team: contact us

From Product Display to Decision Partnership in Stability Solutions

Precision gear procurement should not stop at sample evaluation but extend into long-term stability decision support. Xiamen Ruicheng integrates material assessment, mold engineering, and process validation into a unified service model, enabling customers to foresee risks and costs before committing. This shift from “selling parts” to “supporting decisions” is becoming a key differentiator in advanced injection molding.

1.Early assessment: Identify dimensional stability risks at the concept stage.

2.Co-developed solutions: Define molding strategies aligned with real operating conditions.

3.Process validation: Verify long-term performance through pilot production.

4.Mass production assurance: Establish traceable and repeatable manufacturing systems.

FAQ – Buyer-Oriented Decision Support

Question 1: What standards does your company use to ensure dimensional stability of precision injection-molded gears?

Answer: Key dimensional tolerances are defined based on application requirements and verified through in-process inspection and long-term simulation testing.

Question 2: What information is required for custom gear development?

Answer: Engineering drawings, operating environment, load conditions, and expected service life enable rapid feasibility analysis and proposal development.

Question 3: How do delivery timelines vary by order volume?

Answer: Different scheduling strategies are applied for pilot runs and mass production while maintaining dimensional consistency.

Question 4: How are dimensional deviations handled after delivery?

Answer: A standardized reinspection process identifies root causes, followed by corrective actions or replacement as defined by responsibility agreements.

Question 5: Do you support continuous process optimization during long-term cooperation?

Answer: Yes, process parameters can be continuously refined to match lifecycle changes and performance requirements.

Conclusion

Dimensional stability of precision instrument gears is not a single-factor issue but the result of coordinated material, process, and decision-level control. A systematic injection molding strategy reduces long-term risks while improving reliability and scalability. Choosing a partner with decision-support capability is the key to achieving stable mass production. Xiamen Ruicheng applies this philosophy across every precision gear project.

For expert assistance in implementing solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!