Introduction

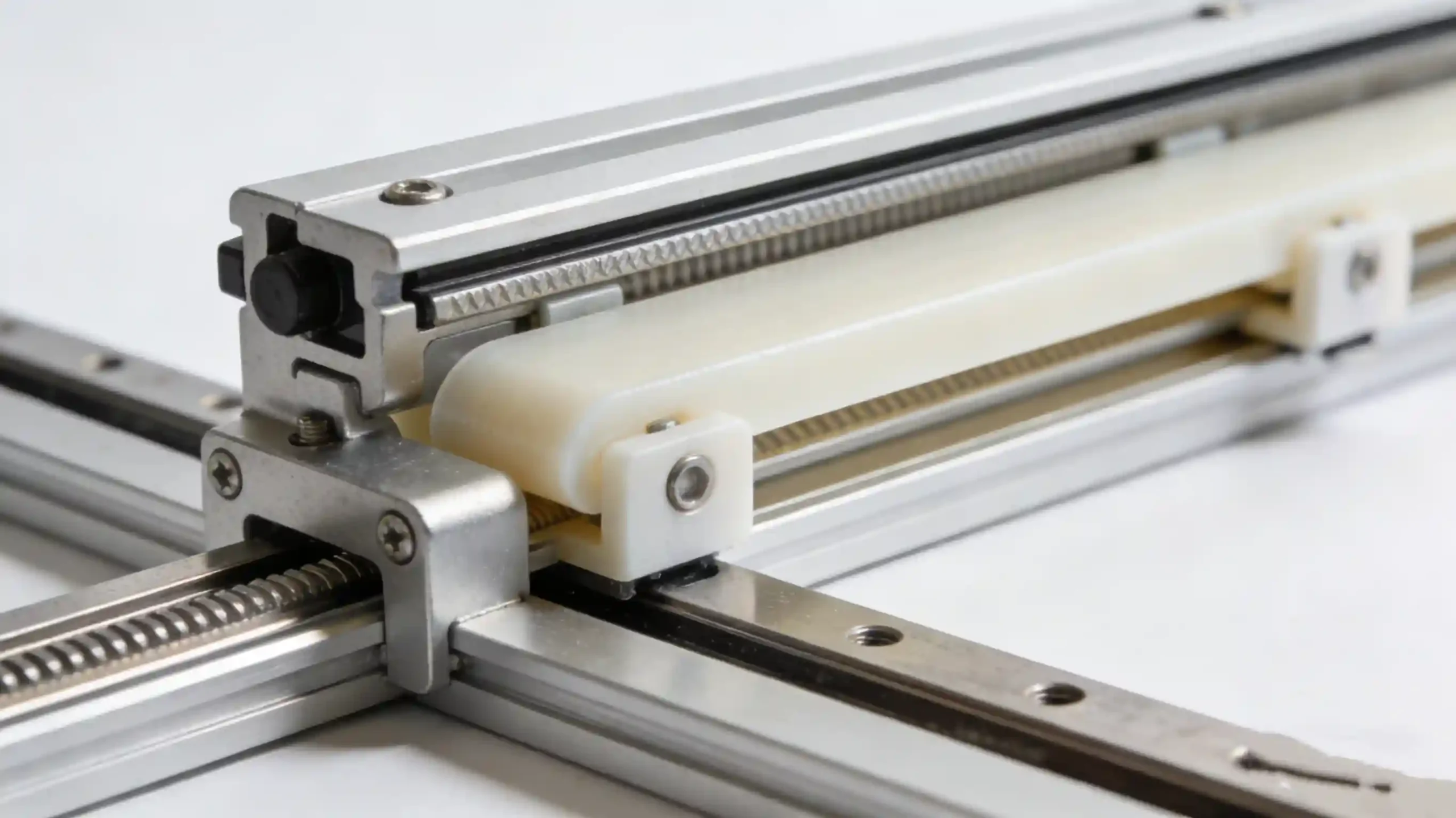

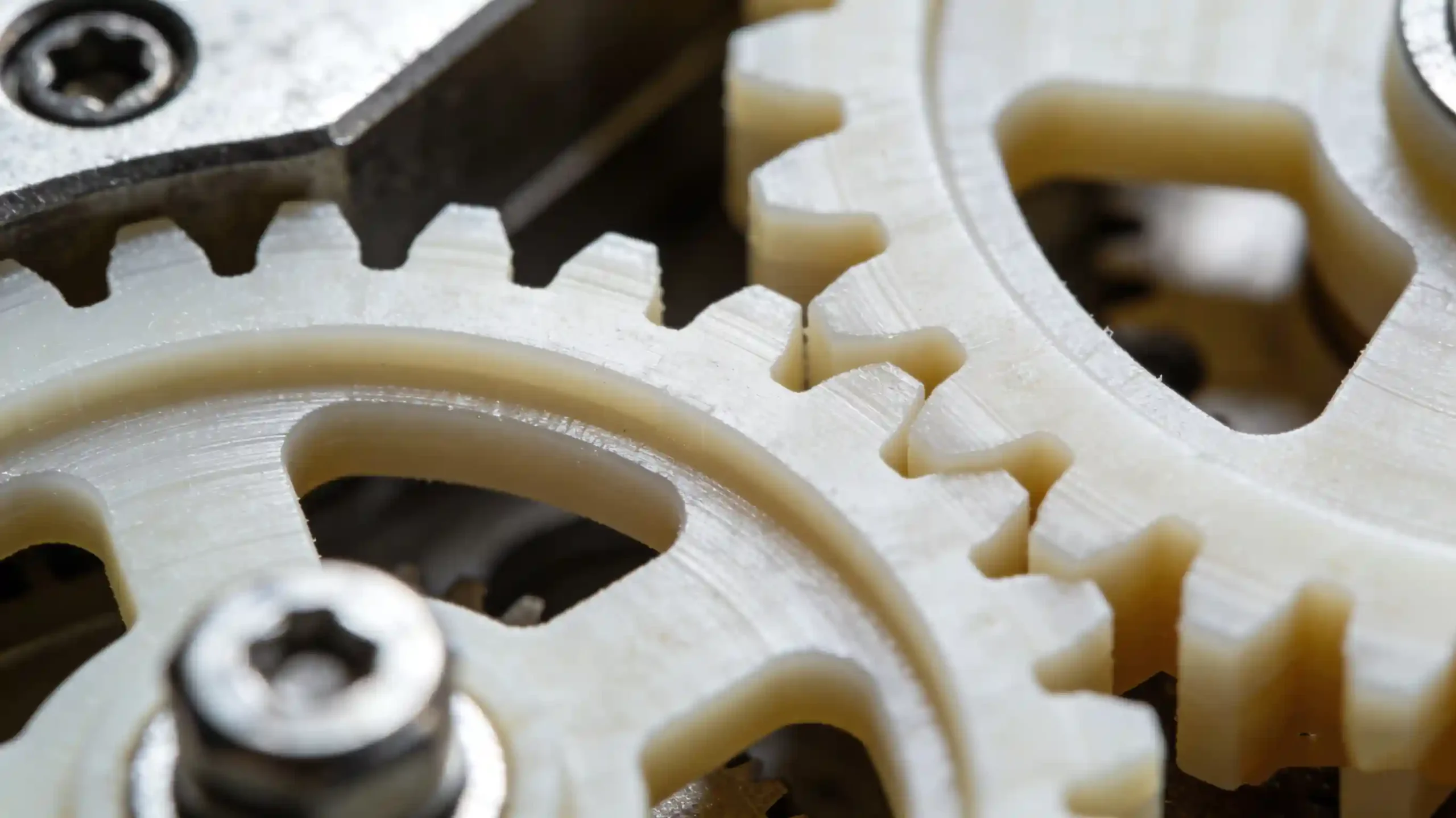

The stable operation of precision machinery relies heavily on the long-term consistency of transmission components, and material selection often defines the upper limit of system lifespan. As a key engineering plastic, POM is widely used in injection-molded transmission structures that demand wear resistance, self-lubrication, and dimensional stability.

Under complex working conditions, performance is never determined by a single property, but by the overall compatibility between design, process, and application environment. Selecting the right POM injection solution is often more effective in reducing system risk than simply pursuing high numerical specifications.

Why Do Precision Machines Prefer POM Wear-Resistant Injection-Molded Transmission Parts?

Precision machinery operates under high speed, tight tolerances, and long duty cycles, which place strict requirements on friction control and dimensional retention. POM injection parts can maintain stable performance under fluctuating loads while ensuring batch consistency through a mature polyoxymethylene material system. Compared with metal machining solutions, injection molding provides advantages in complex structural integration and noise reduction, making it well suited for modular precision mechanisms. The balance POM achieves between wear resistance and manufacturing controllability is the core logic repeatedly validated by Xiamen Ruicheng in precision transmission projects.

Friction control: Coordinated material and surface behavior reduce meshing losses.

Dimensional stability: Precision is maintained under temperature and humidity variations.

Structural integration: One-shot molding minimizes cumulative assembly errors.

Cost efficiency: Lifecycle cost optimization replaces short-term unit pricing.

⚙️ Choosing the right material system is the first step toward stable precision transmission.

How Can You Verify That the Wear Resistance of POM Injection Parts Is Truly Reliable?

Wear resistance is not a single test value but the result of coupling material formulation, mold design, and real operating conditions, which must be evaluated using wear resistance methodologies aligned with actual loads. Through optimized injection processing, POM reduces debris generation during low-friction operation, protecting adjacent components and extending system life. True reliability is reflected in stable performance trends over long-term operation rather than impressive initial data. At Xiamen Ruicheng, operating-condition simulation is introduced early to minimize selection errors.

Condition matching: Wear performance must correspond to real loads and speeds.

Long-term testing: Short tests cannot reflect actual wear evolution.

System interaction: Performance depends on mating parts and lubrication states.

Data traceability: Stable batch control matters more than peak values.

🧩 Wear resistance is about predictability over time, not numbers on paper.

How Does the Injection Molding Process Affect the Accuracy and Service Life of POM Transmission Parts?

Even minor variations in injection parameters can be amplified in the operating behavior of precision transmission systems, especially in crystallinity control and cooling uniformity, which strongly influence final dimensional stability. A well-defined injection molding window reduces internal stress concentration and lowers early failure risk. Process stability often plays a greater role in service life than one-time molding accuracy,which is why Xiamen Ruicheng insists on process validation before mass production.

Thermal strategy: Balanced cooling prevents localized shrinkage.

Flow design: Minimizes performance deviation caused by molecular orientation.

Mold precision: Cavity consistency defines batch consistency.

Process monitoring: Stable parameters ensure predictable lifespan.

🔧 Injection molding is the key to converting material potential into reliability.

Comparison of POM Injection Solutions for Different Precision Transmission Applications

| Application Scenario | Primary Demand | Design Focus | Risk Concern |

|---|---|---|---|

| Gear transmission | Low noise | Tooth profile accuracy | Wear accumulation |

| Sliding mechanism | Smooth motion | Surface condition | Sticking risk |

| Coupling structure | Dimensional stability | Structural symmetry | Stress concentration |

| Integrated assemblies | High integration | One-piece molding | Tolerance stack-up |

Wondering which solution best fits your project? Feel free to contact us.

From Product Display to Decision Partnership

Procurement for precision machinery should not stop at sample comparison but extend to long-term operational risk management. By clarifying requirements early and jointly evaluating material-process compatibility, the optimal injection route can be locked in before mass production. A mature supply model supports customers by reducing uncertainty throughout the decision-making process. Xiamen Ruicheng emphasizes transparent processes and technical consensus rather than one-way quotations.

1.Requirement breakdown: Define real operating conditions and performance limits.

2.Solution validation: Use samples and testing to lower decision risk.

3.Mass-production planning: Balance delivery schedules with consistency.

4.Ongoing support: Provide lifecycle technical feedback.

FAQ

Question 1: What are the core advantages of your POM wear-resistant injection-molded transmission components for precision machinery?

Answer: We align wear life, dimensional accuracy, and operating environment requirements, defining clear performance boundaries and ensuring long-term consistency through process control and batch traceability.

Question 2: What information should we prepare to quickly initiate a customized project?

Answer: Basic drawings, operating condition descriptions, and expected service life targets allow us to assess feasibility before moving into quotation and sample validation.

Question 3: How do delivery and cooperation models differ across order volumes?

Answer: Small batches prioritize validation speed, while large volumes emphasize stable delivery, with capacity planning adjusted accordingly.

Question 4: How are performance deviations handled after delivery?

Answer: Issues are evaluated against pre-confirmed technical standards, followed by corrective actions such as replacement or process adjustment within the agreed timeframe.

Question 5: Do you support customization for special operating conditions?

Answer: Yes, targeted design optimization is available once operating parameters are clarified, with cycle time and cost impact assessed in advance.

Conclusion

Selecting transmission components for precision machinery is a system-level decision where material, process, and application environment must work together. POM injection solutions enable a long-term balance between performance and cost when evaluated holistically. Reliable choices come from understanding and controlling lifecycle risks rather than comparing isolated parameters. Partnering with a supplier that supports decision-making ensures precision systems operate longer and more steadily.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!