Introduction

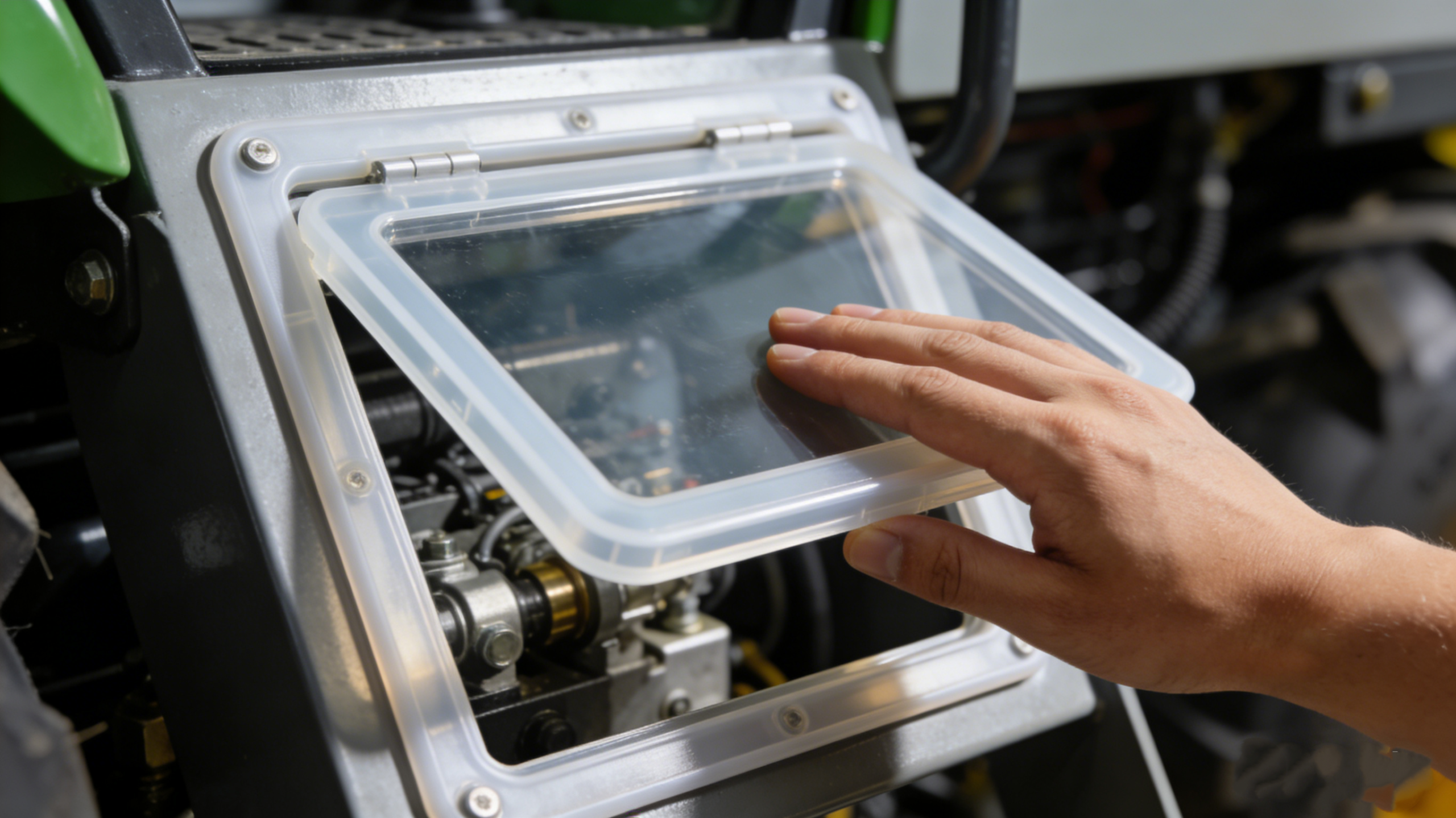

Transparent components used in agricultural machinery play multiple roles, including visibility, protection, and structural stability, making material selection a critical factor in overall equipment reliability. Compared with conventional transparent materials, PC injection molded parts demonstrate more stable performance under complex agricultural working conditions.Locking in the right transparent material at the procurement stage can significantly reduce hidden costs caused by later failures and replacements.

As procurement thinking shifts from simple product display to decision companionship, buyers focus less on raw parameters and more on real-world risk control. PC injection molded parts are increasingly prioritized precisely because they align with this decision-oriented logic.

Why are transparent parts in agricultural machinery more prone to on-site damage?

Agricultural machinery transparent parts are continuously exposed to high impact, strong vibration, and harsh climates, causing many materials to crack, yellow, or fail structurally over time. In contrast, PC injection molded parts rely on excellent impact resistance and molecular stability to deliver more reliable performance. Once a transparent part fails, it not only affects operational judgment but may also trigger broader equipment safety risks. By evaluating polycarbonate and injection molding during material selection, procurement teams can reduce usage risks at the source.

Impact stress: PC materials absorb energy through toughness when struck by stones or tools, minimizing sudden breakage.

Environmental adaptability: PC transparent parts maintain stable mechanical properties under temperature cycling and UV exposure.

Structural integrity: One-piece injection molding eliminates weak joints and improves overall strength.

Long-term cost: Reduced replacement frequency helps control total lifecycle maintenance expenses.

🙂 Choosing PC injection molded parts is essentially an upfront investment in durability.

How do PC injection molded parts reduce maintenance risks for transparent components?

During the operational lifecycle of agricultural machinery, maintenance frequency of transparent parts directly affects downtime and efficiency. PC injection molded parts leverage high toughness and consistent processing quality to minimize microcracks and stress concentration over time. Reducing unpredictable maintenance events is a key metric in procurement value assessment. When combined with PC material properties and industrial injection molding quality control, their risk-mitigation advantages become clearer.

Stable transparency: PC resists haze formation, ensuring long-term visual clarity.

Processing consistency: Injection molding guarantees uniform dimensions and performance across batches, reducing assembly deviations.

Fatigue resistance: PC transparent parts are less prone to early failure under repeated vibration.

Service collaboration: Experienced suppliers such as Xiamen Ruicheng can engage early in material and structural optimization.

🔧 PC injection molded parts shift maintenance from reactive fixes to predictable management.

How should buyers evaluate the true value of PC transparent parts at the procurement stage?

When sourcing transparent parts for agricultural machinery, comparing price or basic parameters alone rarely reflects real value. The advantages of PC injection molded parts are more evident in long-term stability and supplier collaboration, which are central to decision companionship. A truly valuable transparent part consistently reduces uncertainty throughout the equipment lifecycle. By referencing engineering plastic applications and supply chain quality management, buyers can build a more complete evaluation framework.

Service life expectation: PC transparent parts allow lifecycle planning during the design phase.

Supporting capability: Custom injection solutions reduce future retooling and rework risks.

Quality traceability: Standardized molding and inspection records enable rapid issue resolution.

Stable partnership: Working with suppliers like Xiamen Ruicheng ensures continuous technical support.

📈 Evaluating PC injection molded parts means evaluating the safety margin of the procurement decision.

Key comparison points for transparent material decisions in agricultural machinery

| Comparison Dimension | PC Injection Parts | Acrylic | Ordinary Glass | Other Transparent Plastics |

|---|---|---|---|---|

| Impact Resistance | High | Medium | Low | Medium |

| Environmental Adaptability | Excellent | Average | Poor | Average |

| Injection Molding Suitability | Stable | Stable | Not applicable | Limited |

| Maintenance Cost | Low | Medium | High | Medium |

If you are reassessing your transparent material strategy for agricultural machinery, now is the right time to engage with a professional team, contact us

From product display to decision logic in PC transparent part applications

The application of PC injection molded parts in agricultural machinery should go beyond surface-level product presentation and into decision logic. By integrating real operating conditions, maintenance models, and supplier collaboration, PC transparent parts become a more reliable option. When procurement focus shifts from unit cost to long-term value, material advantages truly stand out.

1.Application scenarios: Covers cabins, protective covers, and inspection windows.

2.Risk control: Proactively avoids downtime caused by material failure.

3.Collaborative development: Joint optimization of injection structure and thickness with suppliers.

4.Ongoing support: Stable technical response during mass production and after-sales stages.

Frequently Asked Questions (FAQ)

Question: What is the core advantage of your PC injection molded transparent parts for agricultural machinery?

Answer: We use high-impact PC materials combined with stable injection processes and full-process inspection to ensure long-term reliability under harsh agricultural conditions, addressing buyers’ core needs for safety and durability.

Question: What information is required to start a custom PC transparent part project?

Answer: Usage environment details, structural drawings, and expected volumes help Xiamen Ruicheng quickly complete process evaluation and provide actionable quotations.

Question: How are delivery timelines managed for different order volumes?

Answer: Trial and mass-production orders follow different scheduling strategies, with flexible capacity reserved to support urgent requirements.

Question: How are quality or delivery issues handled after procurement?

Answer: Clear quality criteria and response mechanisms ensure timely rework, replacement, or corrective solutions once issues are confirmed.

Question: Can you support customization for special agricultural operating conditions?

Answer: Yes, material and structural adjustments are available based on temperature variation, impact levels, and usage frequency, with clear timelines and cost implications.

Conclusion

In agricultural machinery transparent part procurement, the value of PC injection molded parts extends beyond material performance to comprehensive risk control. By considering operating environments, maintenance models, and supplier collaboration, buyers can make more rational decisions. Prioritizing PC injection molded parts lays a stronger foundation for long-term, stable machinery operation. Partnering with experienced manufacturers such as Xiamen Ruicheng further amplifies this decision advantage.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!