Introduction

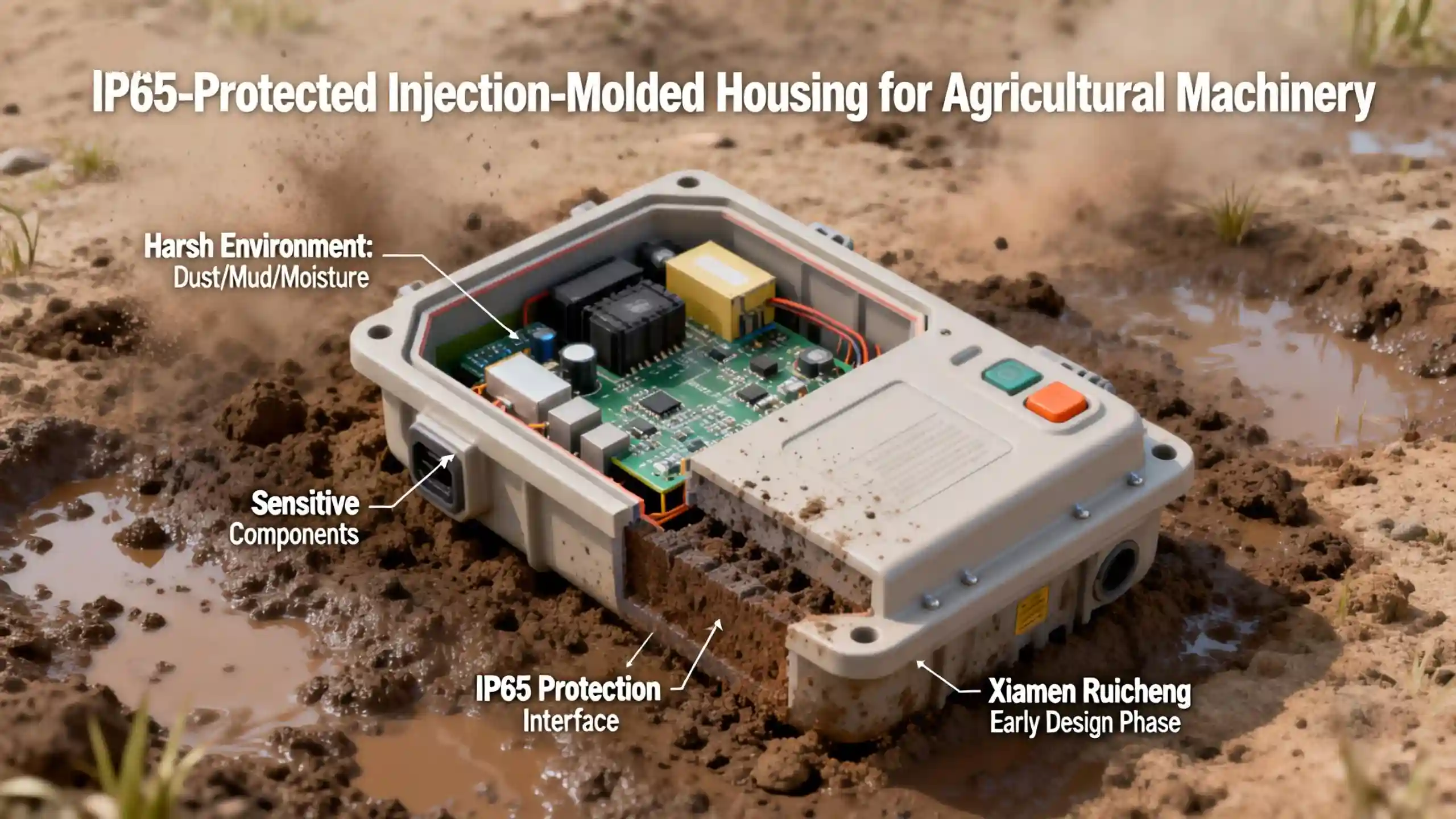

Agricultural machinery often operates under continuous high-temperature exposure, vibration, and long-duty cycles, which places strict demands on the stability of plastic components. Heat-resistant PS injection molded parts are widely used in control housings, protective covers, and internal structural components due to their dimensional consistency and molding stability. The real challenge is not the material datasheet itself, but whether the material can maintain stable performance under real operating conditions.

In real procurement cases, many buyers find that even materials labeled as heat-resistant still deform, age, or fail during assembly. Only by reversing material selection from actual application scenarios can decision risks caused by parameter-only thinking be effectively avoided.

Why must agricultural machinery use heat-resistant PS injection molded parts?

Agricultural machinery is exposed to engine residual heat, direct sunlight, and prolonged operation, which significantly increases thermal stress on plastic components. Standard PS materials tend to soften and lose dimensional accuracy under heat, while modified heat-resistant PS injection molded parts maintain rigidity and surface integrity at elevated temperatures. The true value of heat-resistant PS lies in its ability to retain structural and functional consistency under continuous thermal loads. By systematically evaluating heat-resistant PS material properties and plastic applications in agricultural machinery, long-term maintenance and replacement costs can be effectively reduced.

Thermal stability: The material resists performance degradation under repeated heat cycles, ensuring long-term reliability.

Dimensional retention: Injection molded parts maintain assembly tolerances under heat, preventing loosening or interference.

Processing compatibility: Heat-resistant PS offers stable flow behavior during injection molding, supporting complex geometries.

Cost balance: Compared with high-end engineering plastics, it delivers required heat resistance at a more controllable cost.

🔥 Selecting heat-resistant PS is not about chasing higher numbers, but ensuring predictable performance under real operating conditions.

How can you determine whether heat-resistant PS fits your specific agricultural equipment?

Different agricultural machines vary significantly in heat source location, operating duration, and ambient temperature, which leads to very different material requirements. Relying solely on HDT or Vicat softening point often fails to reflect real-world performance. Only by aligning material selection with equipment structure and usage scenarios can the benefits of heat-resistant PS be fully realized. Referencing injection molded part design principles and plastic heat deformation behavior helps build a more accurate evaluation.

Operating condition mapping: Identify continuous operating temperatures and peak thermal spikes to avoid material mismatch.

Structural compatibility: Evaluate deformation risks based on wall thickness and rib design.

Assembly interaction: Consider thermal expansion differences when mating with metal or other plastic components.

Service life expectation: Assess long-term thermal aging based on expected equipment lifespan.

🧩 True compatibility means aligning material behavior with the real rhythm of machine operation.

What common procurement pitfalls exist when selecting heat-resistant PS injection molded parts?

Many buyers fall into the trap of believing that higher heat-resistance ratings automatically mean higher safety margins, while ignoring processing stability and batch consistency. Over-specifying heat resistance may introduce molding difficulties or unnecessary cost increases. A reliable heat-resistant PS solution balances performance, manufacturability, and supply stability. Combining insights from injection molding process stability and material selection strategies is critical.

Ignoring batch consistency: Material variation between batches can lead to assembly and quality issues.

Overlooking process capability: Existing molding equipment limitations may be incompatible with overly demanding materials.

Underestimating validation effort: Lack of early testing shifts risk into mass production.

Unstable supply chain: Neglecting supplier continuity and technical support increases long-term risk.

⚠️ Avoiding procurement pitfalls is fundamentally about reducing uncontrollable risks before mass production.

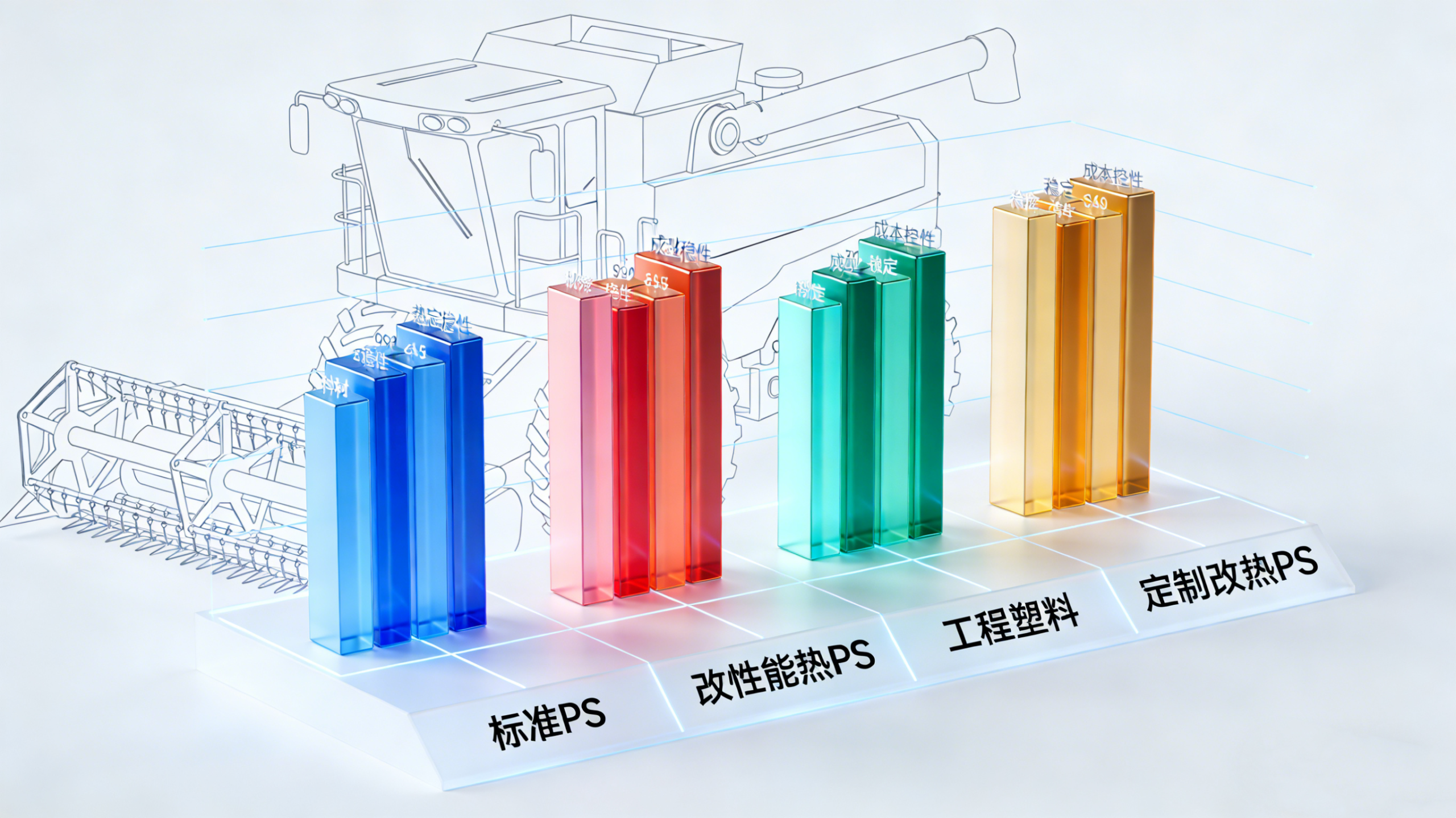

Key Comparison Points for Heat-Resistant PS Solutions in Agricultural Machinery

| Comparison Aspect | Standard PS | Modified Heat-Resistant PS | Engineering Plastics | Customized Heat-Resistant PS |

|---|---|---|---|---|

| Thermal stability | Low | Medium–High | High | Customized to application |

| Molding stability | High | High | Medium | High |

| Cost control | Low | Medium | High | Controllable |

| Application flexibility | Low | Medium | Low | High |

If you are seeking an optimal balance between performance and cost while ensuring application-specific fit, feel free to contact us for direct consultation.

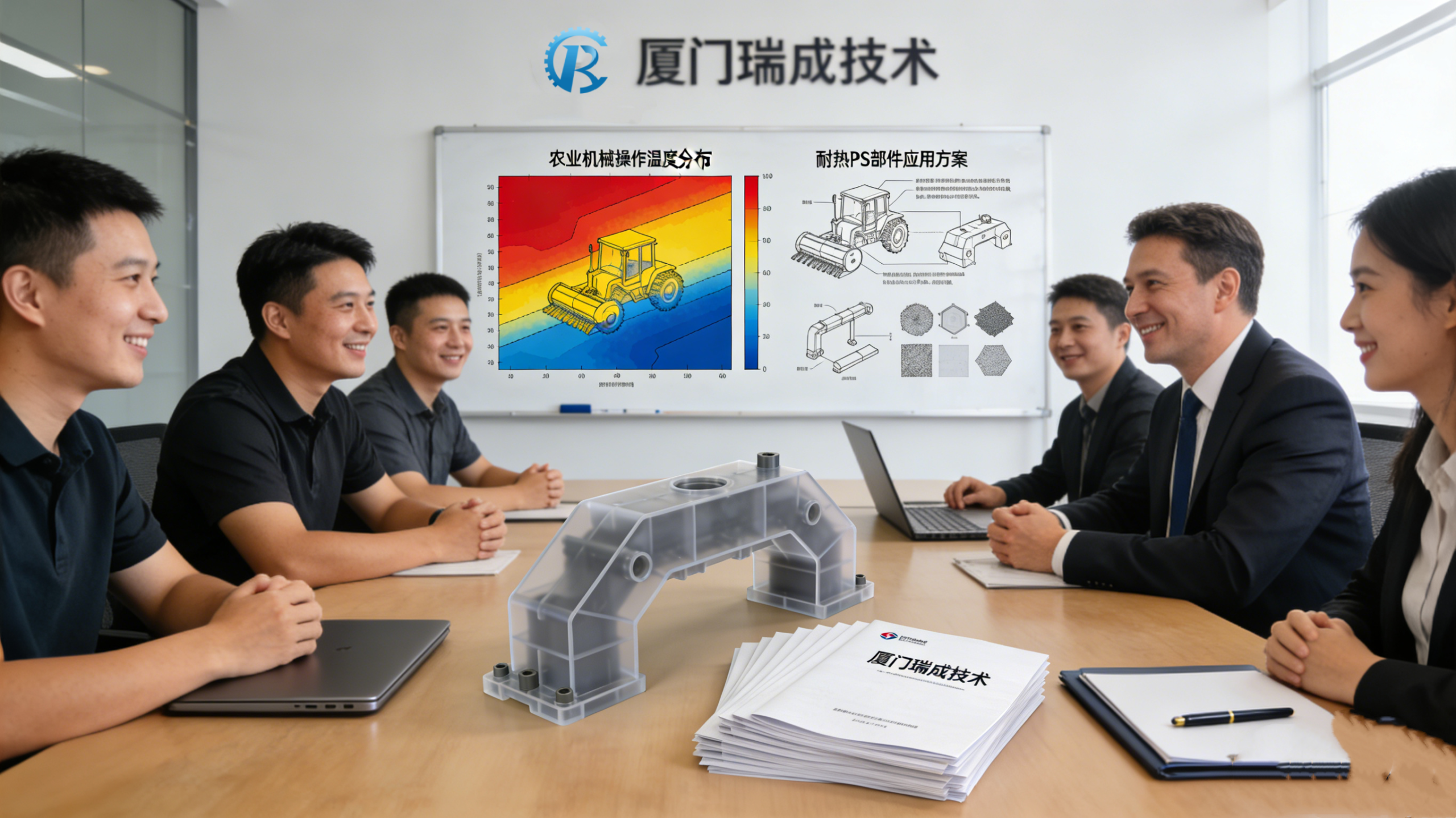

How Xiamen Ruicheng Supports Decision-Making for Heat-Resistant PS Injection Solutions

As a manufacturing partner specializing in injection molding solutions, Xiamen Ruicheng has accumulated extensive experience in heat-resistant PS applications for agricultural machinery. Rather than simply recommending materials, we start from real operating conditions, structural design, and production objectives to build implementable solutions. Shifting material risk forward through early validation and process control is the core of how we support customer decisions.

1.Application-driven material selection: Material choices are defined by real operating environments, not isolated parameters.

2.Process-integrated design: Mold design and injection parameters are optimized together to ensure stable outcomes.

3.Batch consistency assurance: Long-term reliability is ensured through controlled sourcing and process monitoring.

4.Continuous technical support: Data-driven improvement support continues throughout mass production and iteration.

Frequently Asked Questions (FAQ)

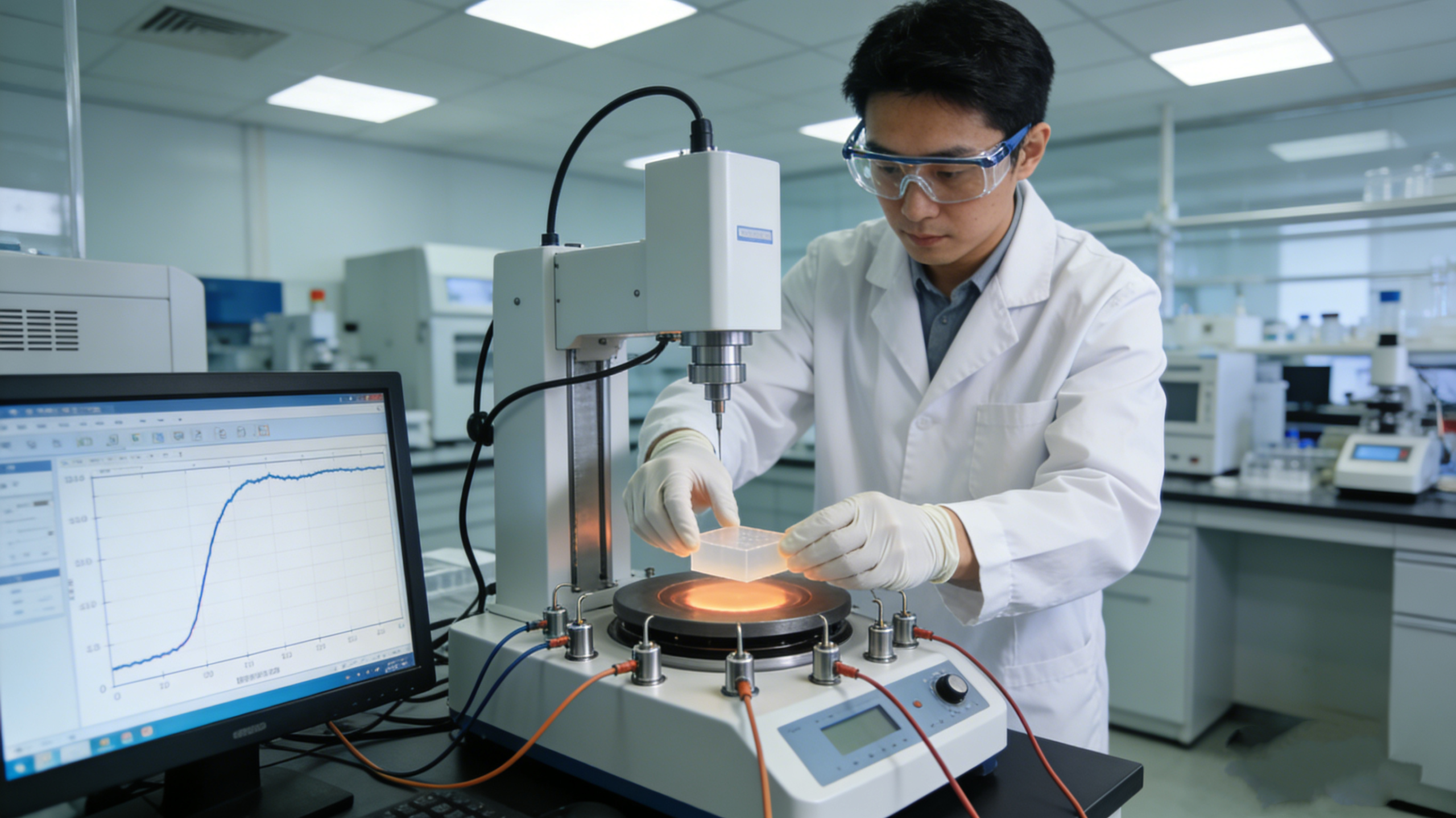

Question: What is the core quality baseline of your heat-resistant PS injection molded parts?

Answer: We focus on real thermal performance under operating conditions, supported by defined temperature ranges, internal validation processes, and ongoing inspection to ensure long-term structural reliability in agricultural machinery.

Question: What information is required to start a customized heat-resistant PS project?

Answer: Providing operating temperature ranges, installation locations, structural drawings, and expected annual volumes allows us to quickly evaluate feasibility and deliver an accurate proposal.

Question: How do MOQ and lead time vary with order volume?

Answer: We support both pilot runs and mass production, with MOQ and lead time flexibly defined based on mold complexity and capacity planning.

Question: How are post-production quality issues handled?

Answer: Xiamen Ruicheng follows a clear issue identification and response process, enabling rapid adjustments to materials or processes to minimize downtime risk.

Question: Can you support customization for special operating conditions?

Answer: Yes, we support tailored solutions for high temperature, vibration, or unique installation constraints, with clear timelines and cost impacts defined at the proposal stage.

Conclusion

Selecting the right heat-resistant PS injection molded parts for agricultural machinery is a systematic decision that integrates operating conditions, structural design, and supply capability. An application-driven selection logic helps avoid hidden risks caused by parameter-only decisions. When material choice and manufacturing strategy form a closed loop, heat-resistant PS components become a reliable part of long-term machine performance.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!