Introduction

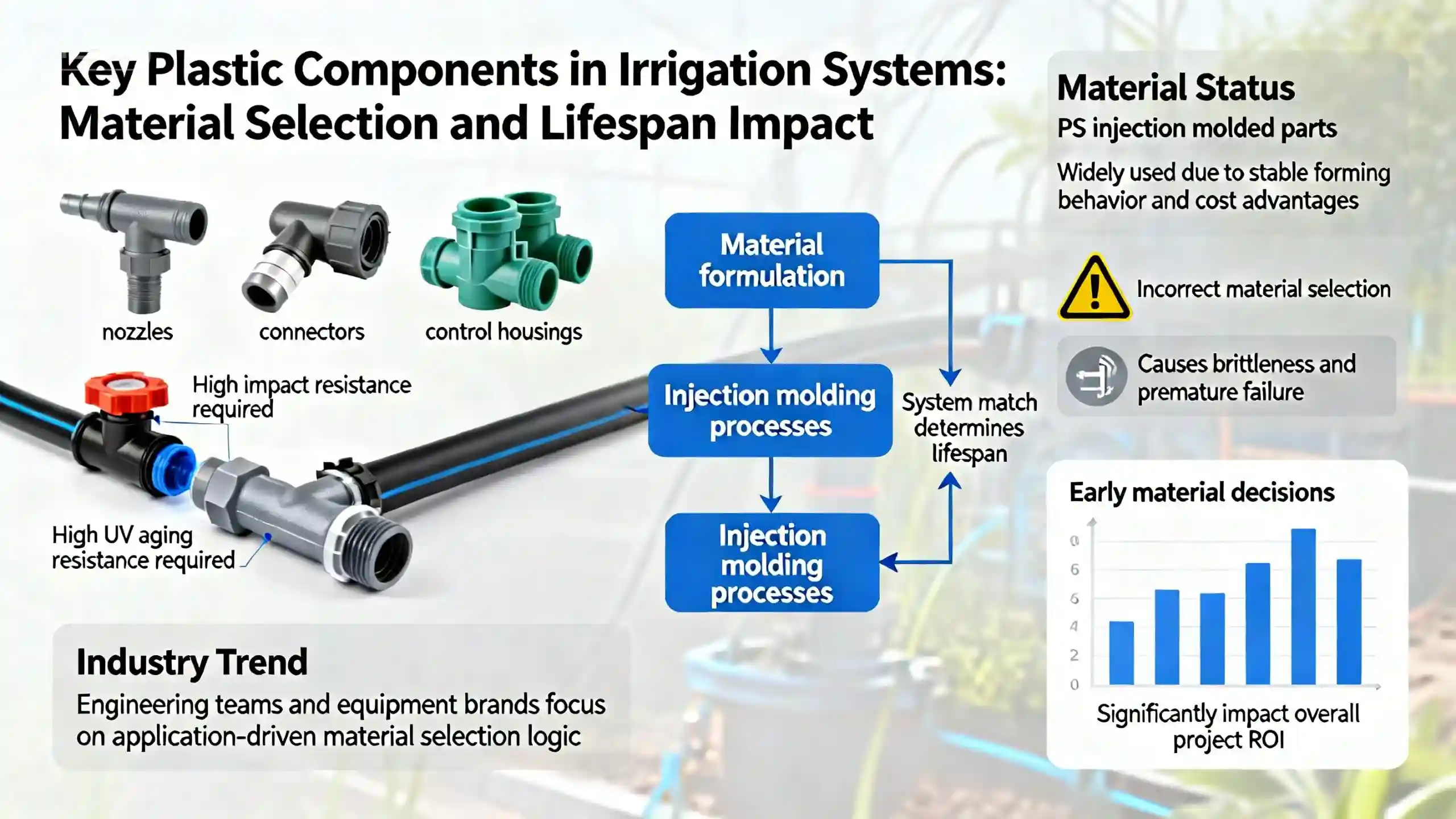

Irrigation equipment is continuously exposed to outdoor environments, placing higher demands on plastic components in terms of impact resistance and UV aging performance, especially for critical parts such as sprinklers, connectors, and control housing shells. PS injection parts are widely used due to their stable molding behavior and cost advantages, but improper material selection often leads to brittleness and premature failure under outdoor conditions.What truly determines the service life of irrigation systems is not a single material parameter, but the systematic match between material formulation and injection molding process.

In real procurement scenarios, more engineering teams and equipment brands are shifting their focus from specification comparison to application-driven material selection logic. Practical experience from Xiamen Ruicheng shows that early-stage selection decisions directly impact overall project ROI.

Why Does the Outdoor Irrigation Environment Accelerate the Failure of PS Injection Parts?

Irrigation equipment typically operates under combined conditions of strong sunlight, high humidity, and repeated mechanical impact, which significantly amplifies the aging risk of PS materials at the molecular level. Ultraviolet radiation damages the molecular chain stability of PS, resulting in reduced impact resistance and progressive embrittlement. Without an effective UV stabilizer system, even initially qualified PS parts will rapidly degrade in outdoor plastics applications.

UV Degradation: Long-term exposure causes surface chalking that gradually penetrates into the structural core.

Thermal Cycling: Day–night temperature variation combined with water pressure generates repeated stress cycles.

Assembly Stress: Installation and maintenance loads amplify cracking risks after material aging.

Maintenance Cost: Frequent component replacement significantly increases total lifecycle cost.

🌞 Outdoor conditions are not a single variable, but a continuous failure multiplier.

How to Balance Impact Resistance and UV Stability When Selecting PS Materials?

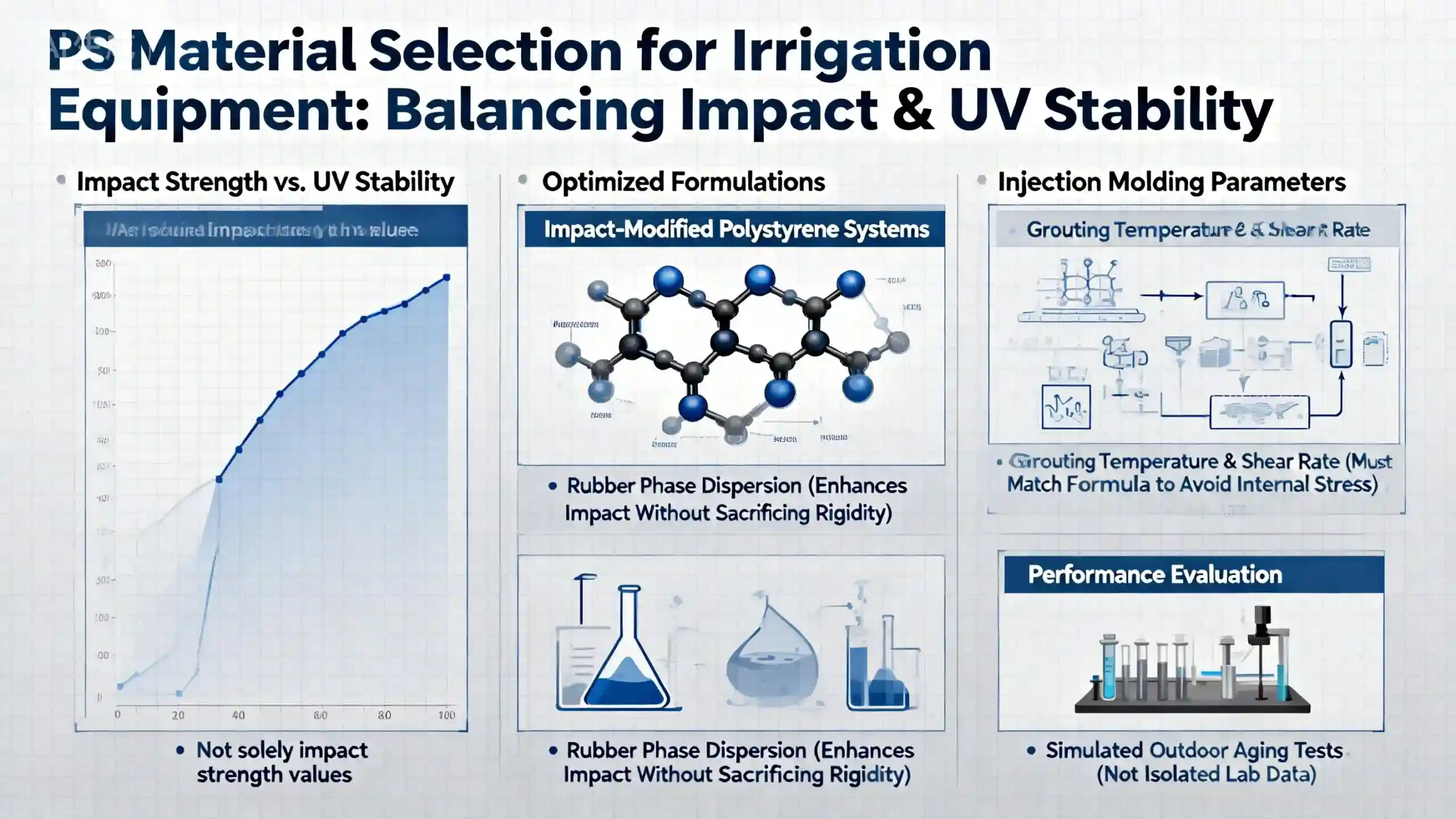

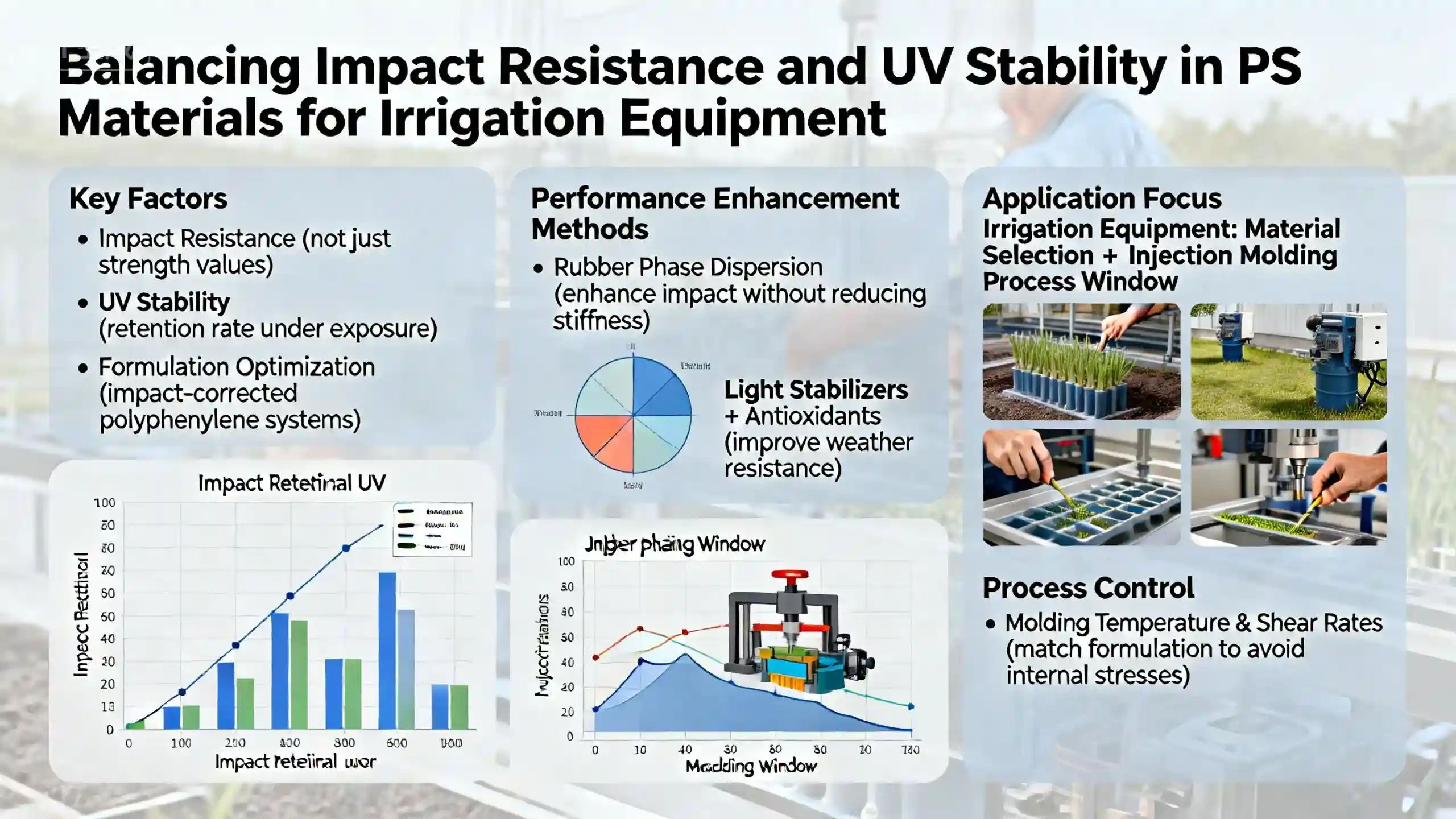

High-impact PS performance is not defined solely by impact strength values, but by its retention rate under UV exposure. Through optimized formulations and impact-modified polystyrene system design, performance degradation can be significantly delayed. In irrigation equipment applications, combining material selection with the injection molding process window is essential for long-term stability.

Modification System: Rubber-phase dispersion enhances impact resistance without excessively sacrificing rigidity.

UV Protection: Incorporating light stabilizers and antioxidant synergies improves weatherability.

Process Compatibility: Injection temperature and shear rate must match the formulation to avoid internal stress.

Application Validation: Performance evaluation should rely on simulated outdoor aging rather than isolated lab data.

🛠️ Reliable material selection comes from balance, not extreme reinforcement.

How Does Injection Molding Affect the Long-Term Aging Resistance of PS Parts?

Even with suitable UV-resistant PS materials, improper injection molding can embed early failure risks. Excessive melt shear and uneven cooling weaken structural stability under UV exposure. When the plastic injection process is poorly controlled, both appearance quality and long-term reliability of PS parts suffer, directly influencing material aging behavior.

Melt Control: Stable melting preserves uniform dispersion of modified components.

Mold Design: Proper gate and runner design minimizes residual internal stress.

Cooling Balance: Uniform cooling prevents localized shrinkage and microcrack formation.

Batch Consistency: Stable processes ensure consistent outdoor performance across production runs.

⚙️ Process details determine whether material performance can truly be realized.

Key Comparison Points for UV-Resistant PS Injection Parts in Irrigation Equipment

| Comparison Dimension | Standard PS | High-Impact PS | UV-Modified PS | Xiamen Ruicheng Solution |

|---|---|---|---|---|

| Impact Stability | Low | Medium | Medium | High |

| UV Durability | Low | Low | Medium | High |

| Outdoor Service Life | Short | Medium | Medium | Long |

| Overall Maintenance Cost | High | Medium | Medium | Low |

Material selection is not only about resin choice, but about system reliability and lifecycle cost control. Learn more about customized solutions and contact us

Decision Path from Selection to Mass Production for Irrigation PS Injection Parts

The successful deployment of UV-resistant high-impact PS injection parts relies on a systematic decision-making process driven by application requirements. Treating material selection as a long-term collaboration decision rather than a one-time purchase is key to risk reduction. Xiamen Ruicheng supports customers through validation, pilot production, and mass manufacturing to ensure stable delivery.

1.Requirement Identification: Define real outdoor conditions and failure risks.

2.Material Verification: Screen solutions through targeted aging and impact tests.

3.Process Lock-In: Establish stable injection parameters during pilot runs.

4.Mass Production Assurance: Maintain batch consistency through process control.

Frequently Asked Questions (FAQ)

Question 1: What are the core advantages of your high-impact PS injection parts for irrigation equipment?

Answer: We focus on impact retention and UV aging resistance, supported by defined formulation strategies and controlled molding processes to ensure long-term outdoor performance and reduced maintenance risk.

Question 2: What information is required to initiate procurement?

Answer: Usage environment, load conditions, annual demand, and assembly requirements help us complete selection evaluation efficiently and propose executable solutions.

Question 3: How do delivery terms vary with different order volumes?

Answer: Small batches support validation phases, while volume orders benefit from production scheduling and raw material locking mechanisms.

Question 4: How are quality or performance issues handled after delivery?

Answer: Clear quality evaluation procedures and responsibility definitions enable rapid root-cause analysis and corrective action.

Question 5: Do you support customization for special operating conditions?

Answer: Yes, formulations and structural designs can be optimized for high UV exposure, strong impact loads, or special installation constraints.

Conclusion

Selecting high-impact UV-resistant PS injection parts for irrigation equipment is fundamentally a system-level decision focused on long-term reliability and cost efficiency. By integrating material modification, UV protection strategy, and injection process optimization, outdoor service life can be significantly extended. Partnering with an experienced manufacturer to move selection decisions forward in the project lifecycle is essential for risk control. Xiamen Ruicheng helps customers transition from product display to true decision partnership.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!