Introduction

In electronics manufacturing, automated logistics, and chemical packaging applications, PE anti-static injection molded parts have become fundamental components for ensuring operational safety and product yield, with their value extending far beyond basic material specifications. What truly drives purchasing decisions is whether a supplier can integrate materials, processing, and certification into a unified, reliable solution rather than merely listing parameters.

As global buyers place increasing emphasis on compliance, SGS certification has evolved into a critical credential for cross-border procurement, directly influencing market access efficiency and total project cost. Injection molding suppliers capable of providing SGS certification and supporting audits and re-testing on an ongoing basis are now pivotal partners throughout the B2B decision chain.

Which suppliers can provide SGS certification?

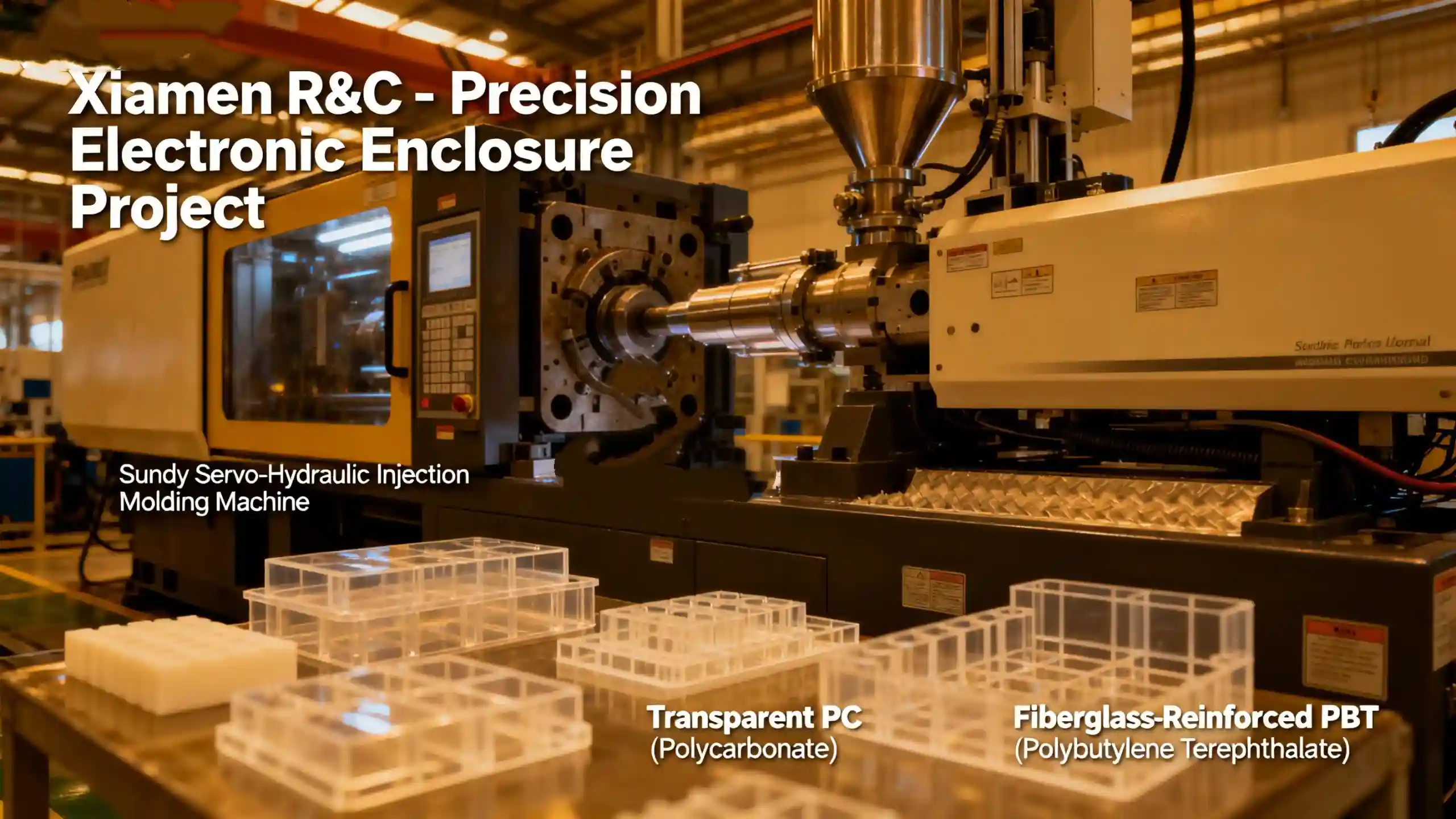

Suppliers capable of delivering SGS-certified PE anti-static injection molded parts typically maintain mature raw material controls and testing systems, enabling consistent performance across mass-production batches, which makes them well suited for long-term cooperation. Represented by Xiamen Ruicheng, such injection molding manufacturers embed certification procedures into their production management through long-term cooperation with third-party testing bodies, significantly reducingcompliance risks for buyers. During evaluation, procurement teams should focus on the coverage of SGS certification and whether the materials meet the industry definition of anti-static plastics, thereby assessing the supplier’s technical depth.

Certification scope: Whether certification covers raw materials, surface resistance, and finished parts determines usability across applications.

Production consistency: Stable molding processes and batch control underpin successful sampling and re-testing.

Documentation readiness: Complete and traceable reports shorten internal approval cycles.

Re-certification capability: Support for annual or project-based re-testing reflects commitment to long-term quality.

📌 Identifying certification-capable suppliers at the outset is key to minimizing downstream uncertainty.

How does SGS certification influence procurement decisions?

SGS certification is not merely a label but a trust mechanism spanning product development, pilot runs, and final delivery, directly affecting internal approvals and customer audits. When PE anti-static injection molded parts are used for export or critical workstations, SGS reports often determine whether a project proceeds. By understanding how surface resistivity and quality management systems are reflected in reports, buyers can better evaluate certification value.

Internal approval efficiency: Standardized reports reduce repetitive clarification.

Customer audit success rate: Third-party validation lowers skepticism.

Upfront risk control: Potential non-compliance issues are identified before mass production.

Long-term cost optimization: Avoids repeated testing and schedule delays.

📌 Certification enables procurement teams to address uncertainty early rather than reactively.

How can buyers assess long-term supplier suitability?

Long-term cooperation depends not only on price or single deliveries but on system robustness, responsiveness, and continuous improvement. In PE anti-static injection projects, Xiamen Ruicheng applies project-based coordination and milestone reviews to establish stable collaboration models. Buyers can assess alignment by reviewing capabilities in injection molding processes and overall supply chain management.

Project coordination model: Dedicated technical and commercial contacts.

Response speed: Transparency and efficiency in addressing issues.

Continuous improvement records: Ability to refine tooling and processes based on feedback.

Capacity flexibility: Stable delivery during demand fluctuations.

📌 Suppliers suited for long-term partnerships demonstrate reliability through operational details.

Comparison of PE anti-static injection supply models

| Comparison Dimension | Trading Supplier | Small Processing Shop | Integrated Molding Manufacturer | Project-Based Partner |

|---|---|---|---|---|

| Certification support | Limited | Unstable | Comprehensive | Comprehensive & customizable |

| Technical involvement | Low | Medium | High | High |

| Risk control | Weak | Medium | Strong | Strong |

| Best fit stage | Trial sourcing | Small batches | Stable mass production | Long-term strategic cooperation |

When selecting suppliers, if you aim to establish a compliant and scalable supply system from the outset, feel free to reach out at contact us

Decision companionship from selection to execution

In sourcing PE anti-static injection molded parts, what is truly scarce is not material data but decision companionship spanning selection, certification, pilot production, and delivery. When suppliers proactively participate in requirement clarification and risk assessment, procurement shifts from passive comparison to active control. This approach is particularly valuable for projects requiring SGS certification support.

1.Requirement clarification: Helping buyers define application scenarios and compliance boundaries.

2.Solution co-development: Avoiding risks early through material and structural planning.

3.Process validation: Building confidence through samples and testing.

4.Ongoing support: Delivering stability and predictability during mass production.

Frequently Asked Questions (FAQ)

Question: What are the most critical evaluation criteria when sourcing SGS-certified PE anti-static injection molded parts?

Answer: Buyers should define required resistance ranges, applicable standards, and SGS test items, and confirm the supplier’s ability to maintain stable mass production and re-testing aligned with real-world risk.

Question: What information is required to initiate cooperation and receive a quotation?

Answer: Typically, application descriptions, target market requirements, estimated volumes, and preliminary drawings enable suppliers to assess certification and process feasibility efficiently.

Question: How do delivery terms and pricing differ across order volumes?

Answer: Small batches emphasize validation and flexibility, while large volumes depend on capacity stability, with lead times and pricing negotiated based on project phase.

Question: How are certification or quality issues handled after delivery?

Answer: Established suppliers define responsibility based on test results and provide rework, re-testing, or replacement solutions with clear response timelines.

Question: Are customized anti-static solutions supported?

Answer: After clarifying operating environments, resistance targets, and service life expectations, suppliers can assess material formulations and tooling adjustments, outlining timelines and cost implications.

Conclusion

When identifying suppliers capable of providing SGS-certified PE anti-static injection molded parts, buyers should shift focus from individual products to comprehensive collaboration capability. Suppliers combining certification expertise, technical depth, and project coordination deliver greater certainty in complex procurement environments. By partnering with injection molding specialists such as Xiamen Ruicheng, companies can reduce compliance risks while gaining sustained decision support throughout their supply chain.

For expert assistance in implementing solutions for your production needs, visit our resource center or

contact us. Let’s help you scale up your manufacturing with precision and efficiency!