Injection Molding Manufacturer in China

What kind of manufacturer do you need?

COMPLETED PROJECTS

Thousands of successful projects delivered, reflecting our extensive experience and reliability.

INDUSTRY EXPERTS

A team of over 100 skilled professionals dedicated to supporting your projects from concept to completion.

ISO-Certified

ISO-compliant for consistent, safe, and high-quality products.

LOW QUANTITY

Starting from 500 pieces, providing flexibility and customization for diverse client needs.

Our plastic injection molding process specializes in manufacturing high-quality plastic components for the medical industry. From custom prototypes to end-use parts, we cater to medical device manufacturers with low MOQs and quick turnaround times. Equipped with injection machines ranging from 80 tons to 1400 tons, we can handle projects of all sizes, ensuring precise tolerances for intricate, small components or robust, larger parts essential for medical applications. Our expertise ensures your medical products meet the highest standards of accuracy and reliability.

We understand that manufacturing plastic medical products comes with its own unique challenges, such as meeting strict regulatory requirements, achieving precise tolerances, and ensuring consistent quality for critical applications. These pain points can be daunting, but as a professional manufacturer, we specialize in addressing and overcoming these obstacles effectively.

Our team is dedicated to delivering reliable solutions throughout the entire injection molding process. From material selection to precision manufacturing, we ensure each part is produced to meet the highest standards, helping you bring safe, high-quality medical products to market with confidence.

Welcome to Your Custom Injection Molding Service

How to get your custom injection-molded products

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

Step 1: PROJECT ANALYSIS & MOULD DESIGN (3-7 days)

At Ruicheng, we start by thoroughly analyzing your project requirements and then proceed to design the mould. Our experienced engineering team uses advanced CAD software to create precise mould designs that ensure high quality and efficiency, tailored specifically to your project’s needs.

Step 2: MOULD MATERIAL PREPARATION (within 1 day)

At Ruicheng, selecting the right mould material is crucial to ensure durability and performance. We begin by understanding the specific requirements of your project, including the type of plastic, production volume, and operating conditions. Our experts then recommend the most suitable mould materials, such as high-grade steel or aluminum, to match your needs. This careful selection process ensures that the moulds we produce are robust, wear-resistant, and capable of delivering high-quality parts consistently.

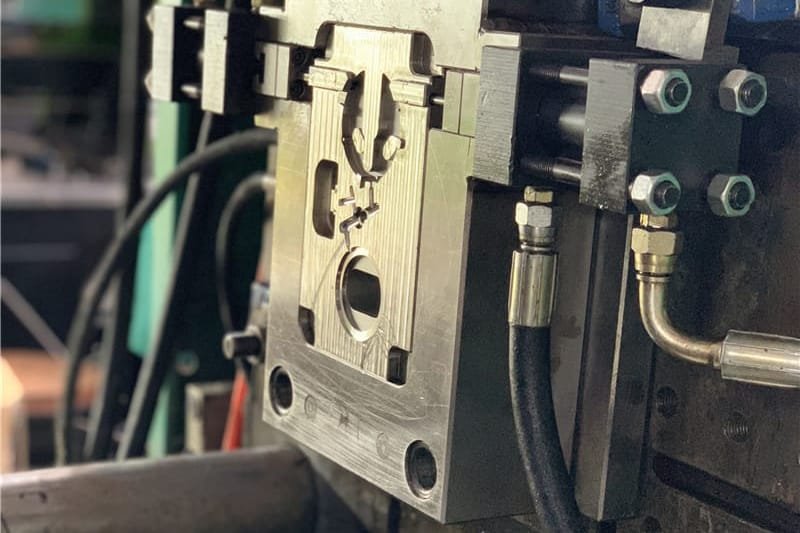

Step 3: MOLD PROCESSING (15-25 days)

At Ruicheng, mold processing is a critical step in ensuring product quality and performance. Our process begins with high-precision CNC machining, which accurately cuts mold materials to the required shapes and dimensions. We then utilize Electrical Discharge Machining (EDM) technology to handle intricate mold details, ensuring precision in every small part. To enhance mold durability, we perform heat treatment and surface treatment, improving the mold’s hardness and corrosion resistance. Finally, we conduct rigorous quality inspections to ensure each mold meets the highest quality standards, providing our clients with the best production solutions.

Step 4: MOULD TRIAL (1-3 days)

The mould trial phase is crucial for validating the mould’s performance and ensuring it meets all project specifications. During this stage, we conduct a series of test runs using the mould to produce sample parts, specifically using black material for T0 samples, as black material most easily reveals any issues. Our team meticulously examines these samples for dimensional accuracy, surface finish, and overall quality. Any necessary adjustments are made to optimize the mould’s performance. This thorough trial process ensures that the mould will produce consistent, high-quality parts in full-scale production, showcasing our commitment to professional and reliable manufacturing solutions.

Step 5: INJECTION PRODUCTION (5-10 days)

In the injection production phase, we transition from testing to full-scale manufacturing. Using advanced injection molding machines, we produce high-quality plastic parts with precision and efficiency. Our automated processes ensure consistent product quality and optimal production speed. Throughout production, we maintain stringent quality control measures, inspecting parts for any defects and ensuring they meet all specifications. This phase is where our expertise and technology come together to deliver reliable and high-performance plastic products to our clients.

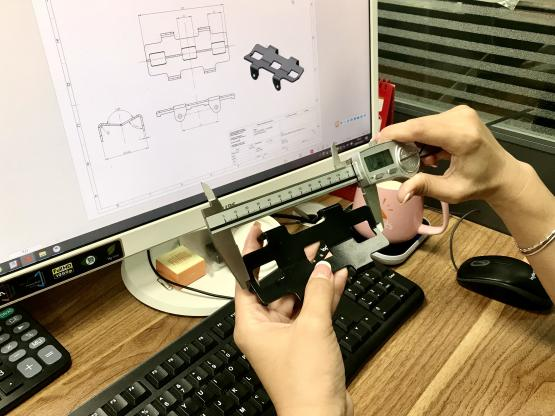

Step 6: PRODCUTS INSPECTION (within 1 day)

In the products inspection phase, we ensure that every produced part meets the highest quality standards. Our inspection process includes rigorous checks for dimensional accuracy, surface finish, and mechanical performance. Using advanced inspection equipment and technologies, such as optical inspection systems and mechanical testing machines, we can identify and correct any potential defects. Through detailed quality reports, we guarantee that all products meet customer requirements and achieve the expected performance standards before final delivery.

Step 7: Package (within 1 day)

In the packaging phase, we ensure that all products are securely packaged to protect them during transit and storage. Each item is carefully wrapped using appropriate protective materials such as bubble wrap, foam inserts, and corrugated boxes. Our packaging process is designed to prevent damage, preserve product integrity, and ensure that all items reach their destination in perfect condition. Clear labeling and detailed documentation are also included to facilitate easy identification and handling. Our commitment to quality extends to every aspect of the process, including packaging, ensuring complete customer satisfaction.

Custom Material Options

We offer a variety of material choices to meet specific durability, flexibility, and aesthetic needs.

Wide Range of Machine Sizes

From 80 to 1400-ton injection machines, we handle both small and large parts with precision.

ISO-Certified Quality Assurance

Our process adheres to ISO standards, guaranteeing consistent quality and reliability.

Low Minimum Order Quantity (MOQ)

Flexible MOQs starting from 500 pieces, allowing for small-batch and prototype runs.

Comprehensive Design Support

From mold design to product optimization, we work closely with you at every stage.

Quick Turnaround Times

Efficient production processes ensure faster lead times without compromising quality.

Expert Problem-Solving Team

Our experienced specialists are here to address any injection molding challenges you face.

Precise Tolerance Capability

Advanced equipment enables us to meet strict tolerance requirements for complex designs.

Application Industry

Syringe

MRI Scanner

Surgical Light Lampshade

Fracture Support Component

If you place an order now, you will enjoy the following free services:

1, Free design improvement suggestions or modification;

2, Free simple DFM report;

3, Free VDI texture catalogue can be shipped by your courier account;