Custom Injection Molding Service

Tight tolerances on complex parts made in the US or internationally.

Our experienced team manages the job for you.

Get a quote today and receive your first mold.

No Minimum Order Quantities

ISO 9001:2015, ISO 13485 & AS9100D certified

DFM feedback from expert engineers

What kind of manufacturer do you need?

Thousands Delivered

Thousands of successful projects delivered, reflecting our extensive experience and reliability

Years of Experience

A team of over 100 skilled professionals dedicated to supporting your projects from concept to completion.

ISO-Certified

ISO-compliant for consistent, safe, and high-quality products.

LOW QUANTITY

Starting from 500 pieces, providing flexibility and customization for diverse client needs.

Our plastic injection molding process is tailored for manufacturers seeking reliable, custom prototypes and end-use parts with low MOQs and quick turnaround times. With a range of injection machines from 80 tons to 1400 tons, we can handle projects of all sizes while maintaining precise tolerances, whether you need small, intricate components or larger, durable parts.

We know that manufacturing challenges like unpredictable lead times, inconsistent quality, and design complexity can be major pain points. That’s why we’re committed to providing consistent quality and expert support throughout the entire injection molding process. Our team ensures each part meets your exact specifications, helping you bring high-quality products to market efficiently and reliably.

Welcome to Your Custom Injection Molding Service

Injection Molding Materials

We have wide selection of more than 100 thermoplastic and thermoset materials. And if you’re looking for alternative material options, check out our guide to resin substitutes for ABS, PC, PP, and other commonly molded plastics.

ABS

Acetal

Acetal Copolymer

Acetal Homopolymer/Delrin

ETPU

HDPE

LCP

LDPE

LLDPE

Nylon

PBT

PC/ABS

PC/PBT

PEEK

PEI

PET

PETG

PMMA (Acrylic, Plexiglas)

Polycarbonate

Polypropylene

PPA

PPE/PS

PS

PSU

TPU

How to get your custom injection-molded products

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

Step 1: PROJECT ANALYSIS & MOULD DESIGN (3-7 days)

At Ruicheng, we carefully analyze your project needs and design precise moulds using advanced CAD software. Our experienced engineers ensure high quality and efficiency, tailored to your requirements.

Step 2: MOULD MATERIAL PREPARATION (within 1 day)

At Ruicheng, we carefully choose the right mould material based on your plastic type, production needs, and working conditions. Our experts recommend durable materials like high-grade steel or aluminum to ensure long-lasting, high-quality mould performance.

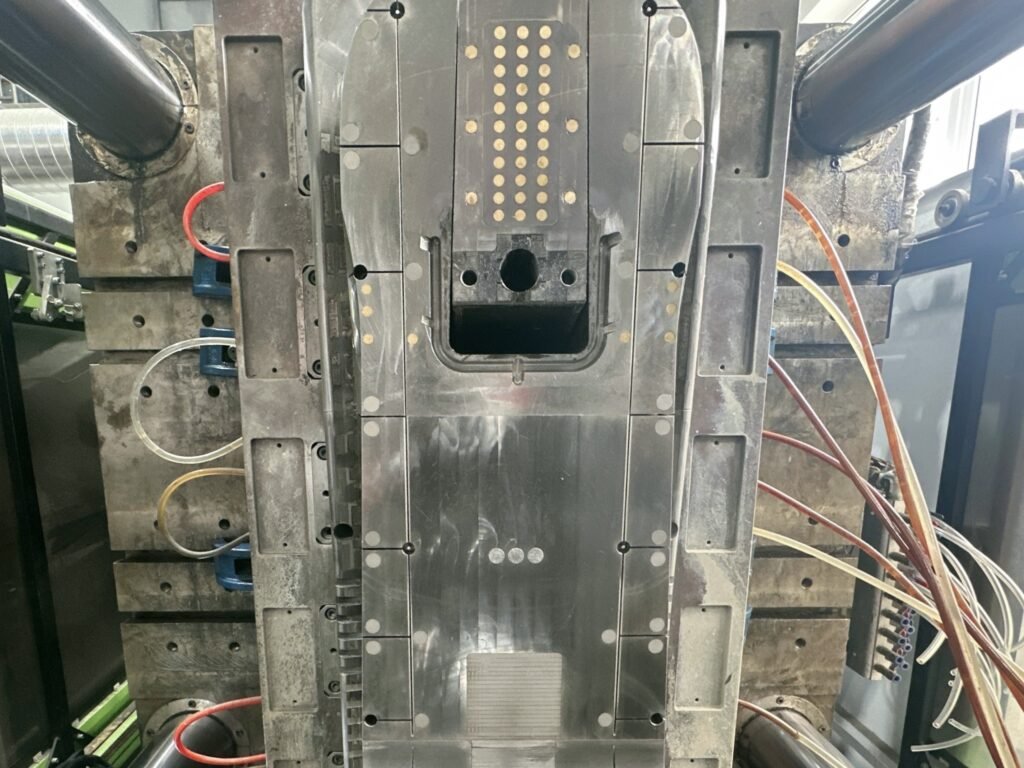

Step 3: MOLD PROCESSING (15-25 days)

we use high-precision CNC machining and EDM technology to craft detailed and accurate molds. Heat and surface treatments enhance durability, while strict quality inspections ensure top performance for every mold.

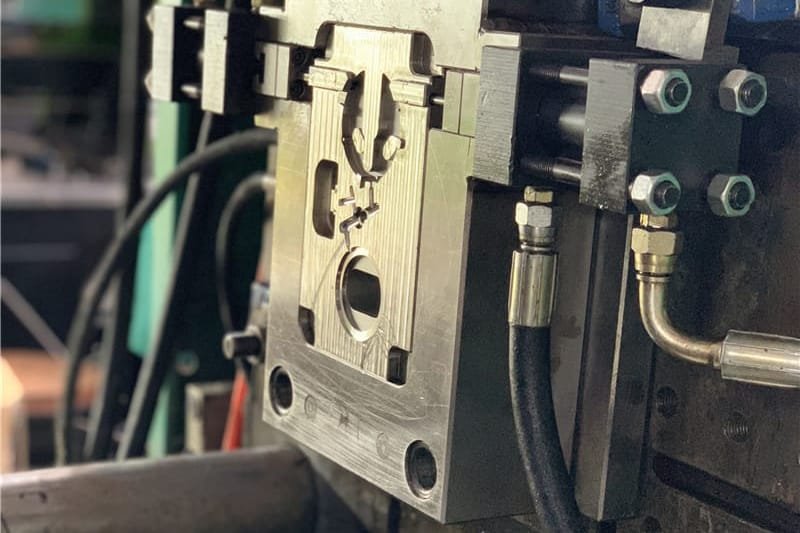

Step 4: MOULD TRIAL (1-3 days)

Mould trials ensure optimal performance and precision. We use black material for T0 samples to spot any issues easily, testing for accuracy and quality. Adjustments are made as needed, guaranteeing consistent, high-quality production.

Step 5: INJECTION PRODUCTION (5-10 days)

We move from testing to full-scale injection molding with advanced machines, ensuring precision and efficiency. Automated processes maintain consistent quality, while strict inspections guarantee defect-free parts that meet all specifications.

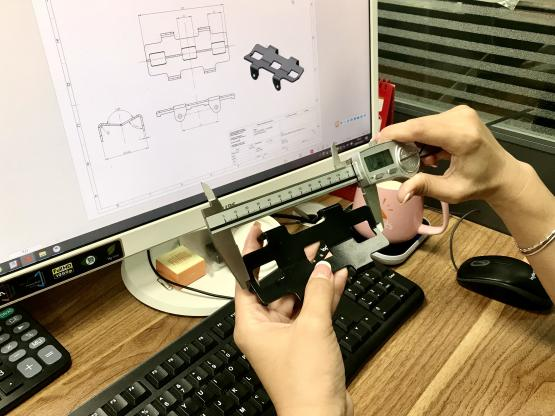

Step 6: PRODCUTS INSPECTION (within 1 day)

We conduct rigorous inspections to ensure every part meets high-quality standards. Using advanced optical and mechanical testing, we detect and correct defects, providing detailed quality reports to guarantee performance before delivery.

Step 7: Package (within 1 day)

At Ruicheng, we use protective packaging like bubble wrap, foam, and sturdy boxes to prevent damage during transit. Clear labeling and detailed documentation ensure safe handling and easy identification, guaranteeing products arrive in perfect condition.

ISO-Certified Quality Assurance

Our process adheres to ISO standards, guaranteeing consistent quality and reliability.

Low Minimum Order Quantity (MOQ)

Flexible MOQs starting from 500 pieces, allowing for small-batch and prototype runs.

Comprehensive Design Support

From mold design to product optimization, we work closely with you at every stage.

Quick Turnaround Times

Efficient production processes ensure faster lead times without compromising quality.

Expert Problem-Solving Team

Our experienced specialists are here to address any injection molding challenges you face.

Precise Tolerance Capability

Advanced equipment enables us to meet strict tolerance requirements for complex designs.

Wide Range of Machine Sizes

From 80 to 1400-ton injection machines, we handle both small and large parts with precision.

ISO-Certified Quality Assurance

Our process adheres to ISO standards, guaranteeing consistent quality and reliability.

Application Industry

Automotive

Medical

Electronics Enclosure

Aerospace

If you place an order now, you will enjoy the following free services:

1, Free design improvement suggestions or modification;

2, Free simple DFM report;

3, Free VDI texture catalogue can be shipped by your courier account;