High-Quality Prototypes, Low-Cost

What Sets Us Apart

Eco-Sustainable

100% recycled plastics processed via energy-smart CNC systems. Zero-waste certified by ISO 14001 reports — eco-accuracy redefined.

Fully Equipped

5-axis CNC for aerospace geometries, 3-axis systems for high-volume precision — ISO-certified across medical, automotive & electronics tooling.

Premium Quality

Aerospace-grade polymers with ISO 9001:2015 certified 99.9% defect-free production. Laser-verified ±0.01mm tolerances — engineered reliability."

Lifetime Service

From delivery to certified maintenance, our 24/7 engineers guarantee 12-hour emergency response — precision sustained beyond production.

Machining Processes

Milling

Engraving

Drilling

Polishing

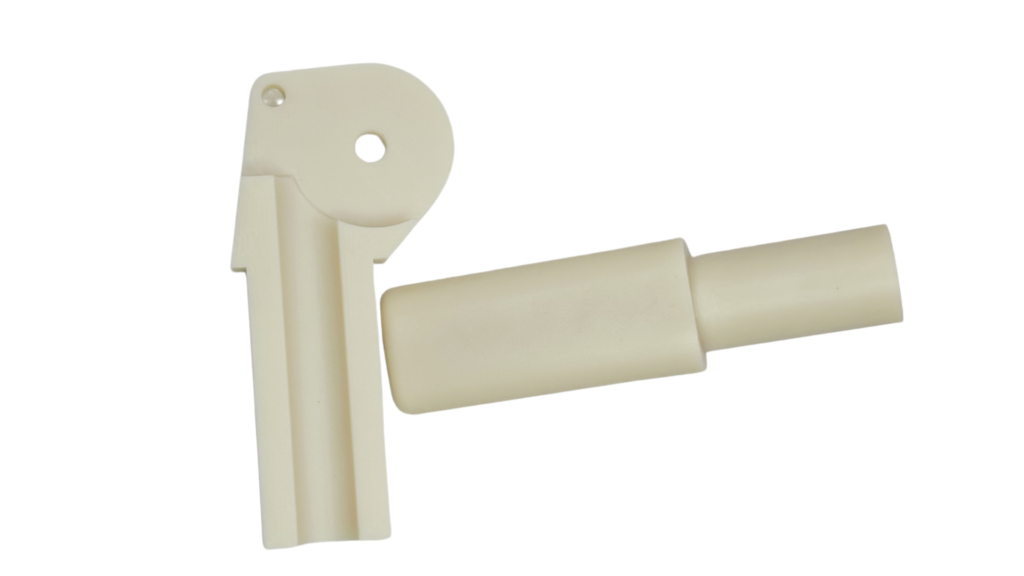

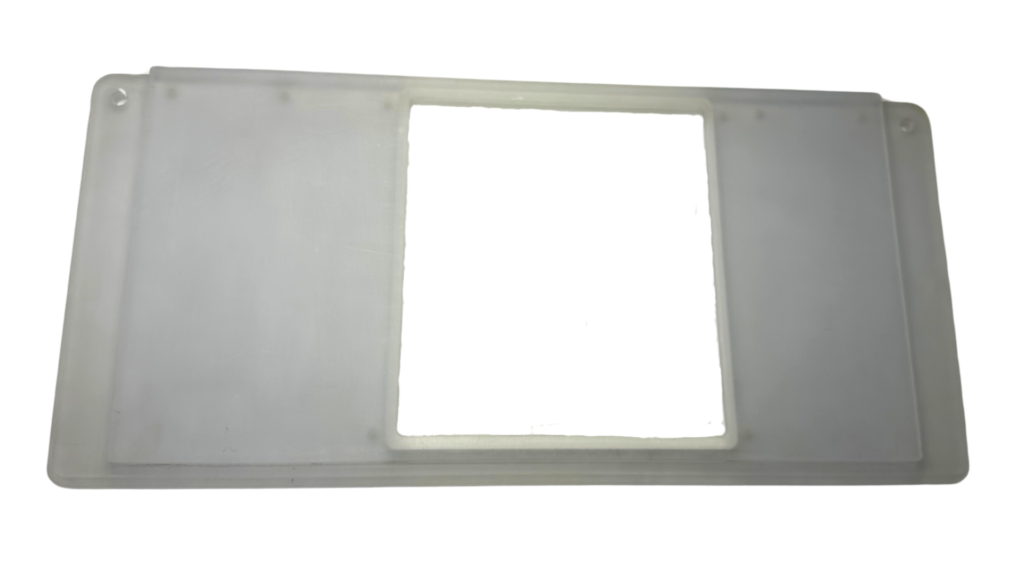

Materials you can choose

ABS

PP

Nylon

Acrylic

PC

OTHER

With You Through Every Process Step

Step 1: Precision Programming Before Production

Before machining begins, we analyze your product and create optimized CNC programs to ensure precision and efficiency.

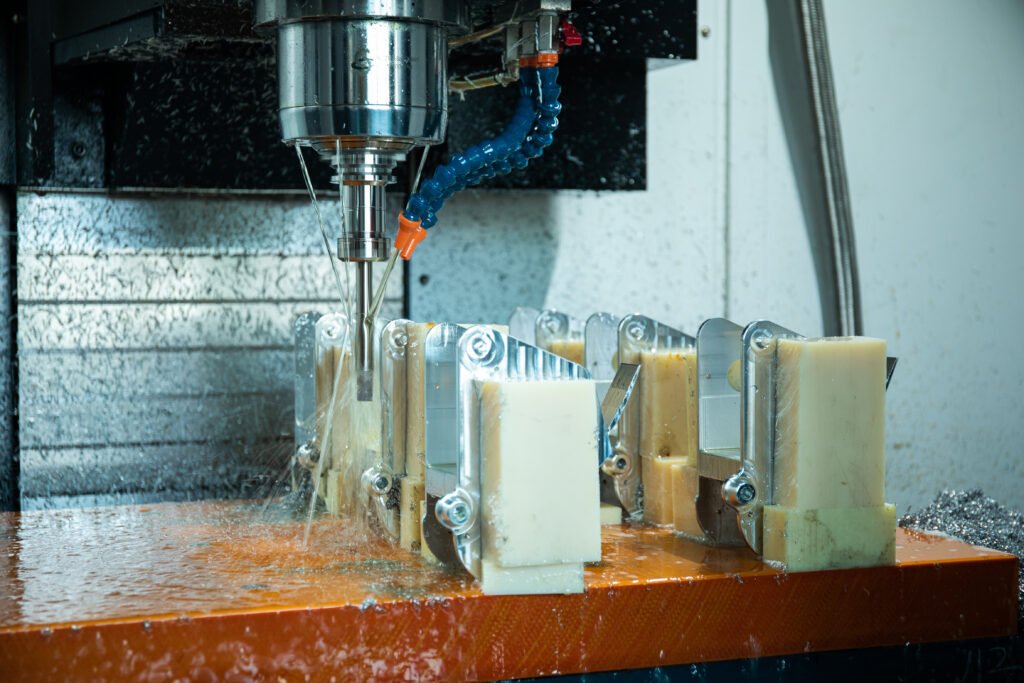

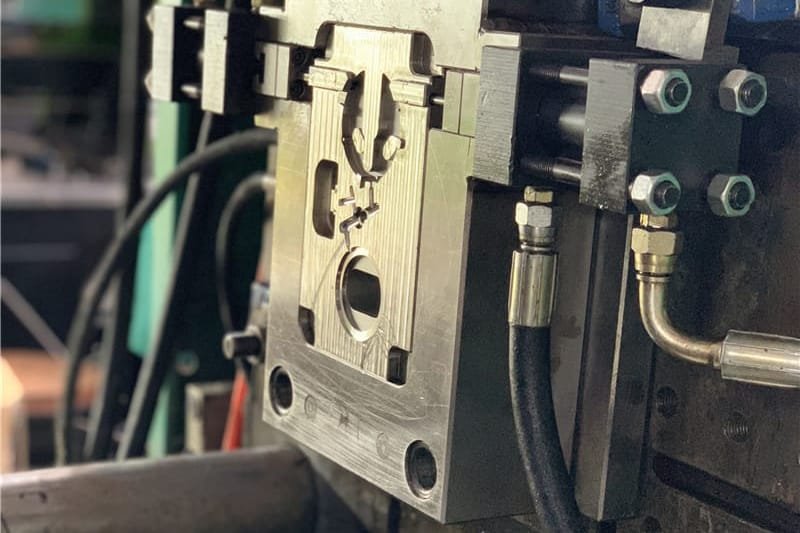

Step 2: High-Speed, High-Accuracy CNC Cutting

With advanced CNC machines, we transform digital designs into high-accuracy parts, ensuring quality in every cut.

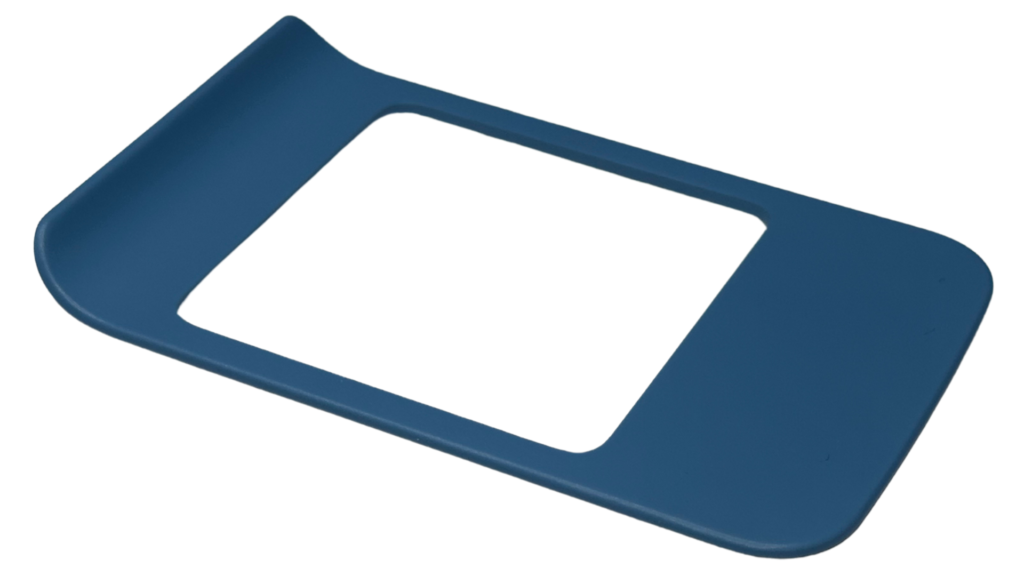

Step 3: CNC Machining Finishes

Standard (As-Milled)

The finish option with the quickest turnaround. Machined parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. CNC machining surface finish is comparable to 125 uin Ra finish.

Bead Blast

The part surface is left with a smooth, matte appearance.

Anodized

Type II (MIL-A-8625, Type II) creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and are usually associated with aluminum. Type III (MIL-A-8625/MIL-PRF-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

PTFE Impregnated Hard Anodize

A hard coat anodize process that embeds PTFE to create a self-lubricating, dry contact surface with Type 3 hard coat’s protective properties. This finish can be used on aluminum alloys or titanium and increases the service life of the product. This finish conforms to the AMS-2482 Type 1 Hard Coat Anodizing with Teflon (Non-Dyed).

Passivation

Improves corrosion resistance for 200 and 300 series and precipitation hardened corrosion-resistant steels. Thickness is negligible, about 0.0000001”. Conforms to ASTM A967, AMS-QQ-P-35, MIL-STD-171, ASTM A380, or AMS 2700.

Powder Coat

This process is where powdered paint is sprayed onto a part and baked in an oven. This creates a strong, wear- and corrosion-resistant, more durable layer than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

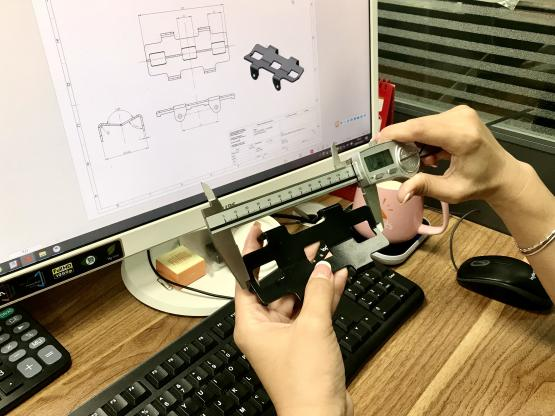

Step 4: PRODCUTS INSPECTION

Does the Standard Inspection include a dimensional report?

No. A standard inspection is a simple dimensional check and no documentation will ship with your parts.

How can I receive a dimensional inspection report?

Upgrade to Formal Inspection with Dimensional Report, CMM Inspection with Dimensional Report, or First Article Inspection to receive a full dimensional inspection report that is correlated to your drawing.

What are your tolerances for CNC machined parts?

- +.005”/-.005” local tolerances across most geometries in metals, +/- 0.010″ for plastics. Will vary for large parts, specifically when holding flatness over large parts after heat treatment.

- Finish requirements for “As Milled” finish will have a minimum 125 surface finish for CNC parts.

- All fabricated parts have a 0.010” dimensional and 1° angular tolerance.

- Tapped holes not explicitly called out as Features on the quoted CAD model may be machined to the diameters specified in that model.

- No surface treatments (e.g. anodize, bead blast, iridite, powder coat, etc.) will be applied unless you have paid for them and we have specifically acknowledged them.

Can you verify GD&T geometric tolerances like position, flatness, surface profile, parallelism, etc..?

- Yes. lf your part has GD&T requirements, it must be inspected using a Coordinate Measuring Machine. Please included your requirements when you placing the order.

Step 5: Package

In the packaging phase, we ensure that all products are securely packaged to protect them during transit and storage. Each item is carefully wrapped using appropriate protective materials such as bubble wrap, foam inserts, and corrugated boxes. Our packaging process is designed to prevent damage, preserve product integrity, and ensure that all items reach their destination in perfect condition. Clear labeling and detailed documentation are also included to facilitate easy identification and handling. Our commitment to quality extends to every aspect of the process, including packaging, ensuring complete customer satisfaction.

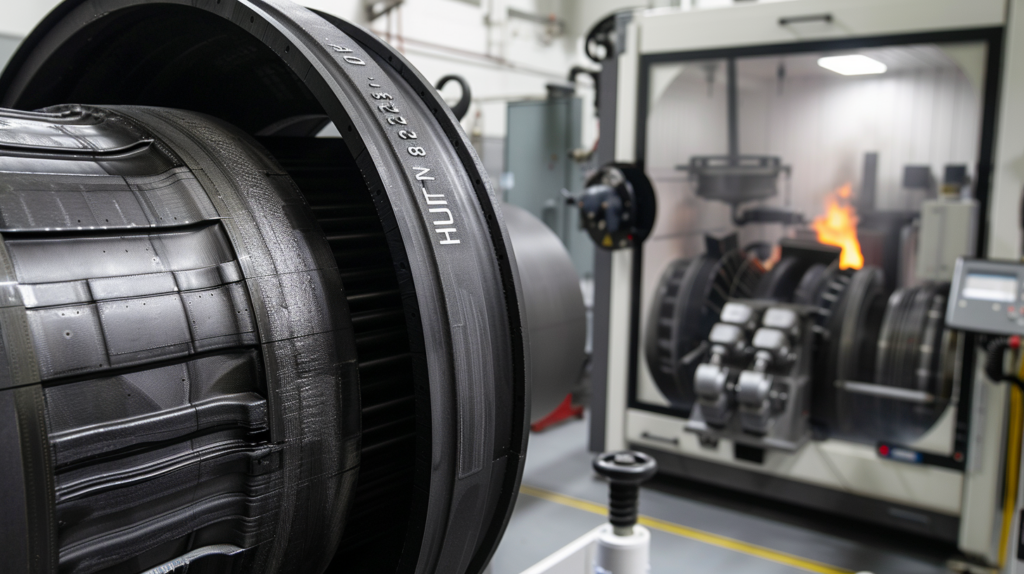

Application Industry

Medical

Automotive

Consumer Electronics

Aerospace

Consumer Goods

Common Questions

Most Popular Questions

This depends on the size of the part. Our team can confirm the estimated production time of the part to you on the day we receive the inquiry.

Drawings in IGS or STEP format, part materials and surface requirements

Plastics (ABS, PC, PMMA, PEEK, PP, PA, PA + 30% GF ect), brass, stainless steel, aluminum alloy, steel

The maximum size that can be processed is 1.8 meters long * 1.3 meters wide * 0.2 meters thick, without disassembling parts

Plastics: polishing, painting, silk screen, electroplating, silk screen, etc.

Metals: polishing, painting, powder coating, anodizing, electroplating, silk screen

Still have questions?

If you place an order now, you will enjoy the following free services:

1, Free design improvement suggestions or modification;

2, Free simple DFM report;

3, Free VDI texture catalogue can be shipped by your courier account;